Abstract

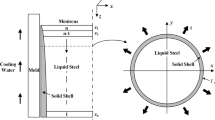

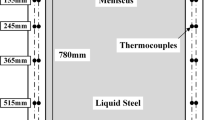

Numerical simulation is the primary approach to evaluate the complex solidification behavior for the continuous casting (CC) process, in which the methods based on the mesh and topology technique have been widely used to solve field variables. For the traditional techniques, such as the finite difference, finite element, and boundary element methods, it is arduous or even impossible to deal with complicated problems that involve multiphase coupling, interface tracking/reconstruction, and self-adaptation due to the inherent weaknesses in the grid structure and mesh dependence. Hence, the present work explores a meshless calculation method for the two-dimensional unsteady heat-transfer problem and proposes an element-free Galerkin (EFG) model for solving heat transfer inside the CC mold based on the moving least-squares approximation. The temperature functions are approximated and constructed by a linear basis and cubic spline weight function over a set of rectangular supporting domain; then, the discrete heat-transfer governing equation based on the EFG method is deduced. The heat flux measured in the real casting process is set as the boundary condition to calculate the nonuniform solidification of the round billet. The calculated results demonstrate that the shell thickness is consistent with that obtained by the square root law of solidification. In addition, the high heat flux region near the meniscus directly determines the growth characteristics of the initial billet shell, which ultimately results in the overall nonuniformity of the shell. The EFG method has the characteristics of fast convergence, high computational accuracy, and great discrete flexibility; it also provides a novel and effective approach for subsequent thermomechanical coupling and crack propagation analysis in the CC process.

Similar content being viewed by others

References

F. Du, X. Wang, X. Han, J. Xu, and M. Yao: Ironmak. Steelmak., 2018, vol. 45, pp. 350–55.

P.H. Hu, X.D. Wang, J.J. Wei, M. Yao, and Q.T. Guo: ISIJ Int., 2018, vol. 58, pp. 892–98.

A.S.M. Jonayat and B.G. Thomas: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 1842–64.

H. Cheng, M.J. Peng, and Y.M. Cheng: Int. J. Numer. Methods Eng., 2018, vol. 114, pp. 321–45.

S. Garg and M. Pant: J. Therm. Stresses, 2017, vol. 40, pp. 846–65.

J.P. Zhang, S.S. Wang, S.G Gong, Q.S. Zuo, and H.Y. Hu: Eng. Anal. Bound. Elem., 2019, vol. 101, pp. 198–213.

L. Zhang, H.F. Shen, Y.M. Rong, and T.Y. Huang: Mater. Sci. Eng. A, 2007, vol. 466, pp. 71–78.

L. Zhang, Y.M. Rong, H.F. Shen, and T.Y. Huang: J. Mater. Process. Technol., 2007, vol. 192, pp. 511–17.

R. Vertnik and B. Sarler: Int. J. Cast Met. Res., 2009, vol. 22, pp. 311–13.

M. Alizadeh, S.A.J. Jahromi, and S.B. Nasihatkon: ISIJ Int., 2010, vol. 50, pp. 411–17.

X. Zhang, X.H. Liu, K.Z. Song, and M.W. Lu: Int. J. Numer. Methods Eng., 2001, vol. 51, pp. 1089–1100.

G.R. Liu and Y.T. Gu: An Introduction to Meshfree Methods and Their Programming, 1st ed., Springer, Dordrecht, 2005, pp. 54–111.

S.S. Pandey, P.K. Kasundra, and S.D. Daxini: Int. J. Theor. Appl. Res. Mech. Eng., 2013, vol. 2, pp. 85–89.

G.R. Liu: Mesh Free Methods Moving Beyond the Finite Element Method, 1st ed., CRC Press LLC, Boca Raton, FL, 2002, pp. 53–265.

J.C. Hostos, A.D. Bencomo, and E.S. Cabrera: Therm. Stresses, 2017, 41, 160–81.

T. Belytschko, Y.Y. Lu, and L. Gu: Int. J. Numer. Methods Eng., 1994, vol. 37, pp. 229–56.

V.P. Nguyen, T. Rabczuk, S. Bordas, and M. Duflot: Math. Comput. Simul., 2008, vol. 79, pp. 763–813.

T.J.R. Hughes: Comput. Meth. Appl. Mech. Eng., 1977, vol. 10, pp. 135–39.

B. Lally, L. Biegler, and H. Henein: Metall. Mater. Trans. B, 1990, vol. 21B, pp. 761–70.

H.B. Yin, M. Yao, and D.C. Fang: ISIJ Int., 2006, vol. 46, pp. 539–45.

X.Z. Zhang and L.J. Xu: Iron Steel, 2005, vol. 40, pp. 25–29.

Acknowledgments

The authors acknowledge the financial support from the National Natural Science Foundation of China (Grant No. 51474047); the Fundamental Research Funds for the Central Universities and the Key Laboratory of Solidification Control and Digital Preparation Technology (Liaoning Province) are also gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted April 2, 2019.

Rights and permissions

About this article

Cite this article

Cai, L., Wang, X., Wang, N. et al. Meshless Method for Nonuniform Heat-Transfer/Solidification Behavior of Continuous Casting Round Billet. Metall Mater Trans B 51, 236–246 (2020). https://doi.org/10.1007/s11663-019-01718-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-019-01718-6