Abstract

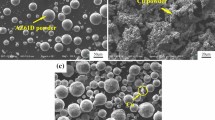

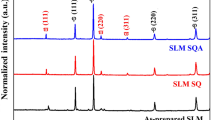

In this study, the microstructure, intermetallic phase, microhardness and wear resistance of unheated and heat-treated Mg-6Al-1Zn-xLa (x = 0.5, 1, 2) alloy that fabricated by selective laser melting was studied. In this paper, La was added by adding La2O3. The grain size was reduced with the La addition which reached smallest with 1% La addition (1.58 μm). The scanning electron microscopy, energy-dispersive x-ray spectroscopy and x-ray diffraction results showed that the secondary phase of Al11La3 was formed during the eutectic reaction. Al11La3 phase still remains after solution treatment at 400 °C for 4h, short rod-shaped discontinuous Mg17Al12 is formed at the grain boundary during aging treatment. The mechanical properties of samples are further improved by aging treatment, microhardness increases with the increase in La content and its value reaches 140 HV for aging-treated Mg-6Al-1Zn-2La. The micro-scratch results show that the wear resistance is related to the La percent and heat treatment method. The residual depth of samples indicates that the addition of La can reduce the micro-wear and short rod-like precipitation of β phase which generates in aging treatment can decrease residual depth as well.

Similar content being viewed by others

References

X.B. Liu, R.S. Chen and E.H. Han, Effects of Ageing Treatment on Microstructures and Properties of Mg-Gd-Y-Zr Alloys with and Without Zn Additions, J. Alloy. Compd., 2008, 465(1–2), p 232–238.

Y. Estrin, S.S. Nene, B.P. Kashyap, N. Prabhu and T. Al-Samman, New Hot Rolled Mg-4Li-1Ca Alloy: A Potential Candidate for Automotive and Biodegradable Implant Applications, Mater. Lett., 2016, 173, p 252–256.

L. Zhang, Z.Y. Cao, Y.B. Liu, G.H. Su and L.R. Cheng, Effect of Al Content on the Microstructures and Mechanical Properties of Mg-Al alloys, Mater. Sci. Eng. A, 2009, 508(1–2), p p129-133.

M. Zhang, C.J. Chen, C. Liu and S.Q. Wang, Study on Porous Mg-Zn-Zr ZK61 Alloys Produced by Laser Additive Manufacturing, Metals, 2018, 8(8), p 635–653.

A. Simch and H. Pohl, Direct Laser Sintering of Iron-Graphite Powder Mixture, Mater. Sci. Eng. A, 2004, 383(2), p 191–200.

M. Salehi, S. Maleksaeedi, H. Farnoush, N.M.L. Sharon, G.K. Meenashisundaram and M. Gupta, An Investigation into Interaction Between Magnesium Powder and Ar Gas: Implications for Selective Laser Melting of Magnesium, Powder Technol., 2018, 333, p 252–261.

D. Herzog, V. Seyda, E. Wycisk and C. ClausEmmelmann, Additive Manufacturing of Metals, Acta Mater., 2016, 117, p 371–392.

B.C. Zhang, H.L. Liao and C. Coddet, Effects of Processing Parameters on Properties of Selective Laser Melting Mg-9%Al Powder Mixture, Mater. Des., 2012, 34, p 753–758.

Y. Li, J. Zhou, P. Pavanram, M.A. Leeflang, L.I. Fockaert, B. Pouran, N. Tümer, K.U. Schröder, J.M.C. Mol, H. Weinans, H. Jahr and A.A. Zadpoor, Additively Manufactured Biodegradable Porous Magnesium, Acta Biomater., 2018, 67, p 378–392.

A.K. Chaubey, S. Scudino, K.G. Prashanth and J. Eckert, Microstructure and Mechanical Properties of Mg-Al-Based Alloy Modified with Cerium, Mater. Sci. Eng. A, 2015, 625, p 46–49.

W.J. Liu, F.H. Cao, L.R. Chang, Z. Zhang and J.Q. Zhang, Effect of Rare Earth Element Ce and La on Corrosion Behavior of AM60 Magnesium Alloy, Corros. Sci., 2009, 51(6), p 1334–1343.

J.B. Liu, K. Zhang, J.T. Han, X.G. Li, Y.J. Li, M.L. Ma, J.W. Yuan, G.L. Shi, M. Li and C.F. Lu, Study on the Microstructure and Mechanical Properties of WE71 Magnesium Alloy, Mater. Sci. Eng. A, 2015, 625, p 107–113.

H. Somekawa, Y. Osawa, A. Singh, K. Washio, A. Kato and M. Toshiji, Effect of Micro-alloying Elements on Deformation Behavior in Mg-Y Binary Alloys, Mater. Trans., 2014, 55(1), p 182–187.

G.X. Xu, Rare Earth, Metallurgical Industry Press, Beijing, 1995, p 56

K.M. Asl, A. Masoudi and F. Khomamizadeh, The Effect of Different Rare Earth Elements Content on Microstructure, Mechanical and Wear Behavior of Mg-Al-Zn Alloy, Mater. Sci. Eng. A, 2010, 527(7–8), p 2027–2035.

H. Yan and Z.W. Wang, Effect of Heat Treatment on Wear Properties of Extruded AZ91 Alloy Treated with Yttrium, J. Rare Earths, 2016, 34(3), p 308–314.

J.H. Zhang, M.L. Zhang, J. Meng, R.Z. Wu and D.X. Tang, Microstructures and Mechanical Properties of Heat-Resistant High-Pressure Die-Cast Mg-4Al-xLa-0.3Mn (x = 1, 2, 4, 6) Alloys, Mater. Sci. Eng. A, 2010, 527(10–11), p 2527–2537.

Q. Yang, F.Q. Bu, T. Zheng, F.Z. Meng, X.J. Liu, D.P. Zhang, X. Qiu and J. Meng, Influence of Trace Sr Additions on the Microstructures and the Mechanical Properties of Mg-Al-La-Based Alloy, Mater. Sci. Eng. A, 2014, 619, p 256–264.

X. Niu, H. Fu and J. Fu, Microstructure and Mechanical Properties of Selective Laser Melted Mg-9wt%Al Powder Mixture, Mater. Lett., 2018, 221, p 4–7.

X.D. Luo, D.L. Qu and G.D. Zhang, Influence of Lanthana on Composition and Structure of Mg-Al Spinel Material Prepared from Decomposed Magnesite, Chin. Rare Earths, 2012, 33, p 59–63.

T. Sakamoto, S. Kukeya and H. Ohfuji, Microstructure and Room and High Temperature Mechanical Properties of Ultrafine Structured Al-5 wt%Y2O3 and Al-5 wt%La2O3 Nanocomposites Fabricated by Mechanical Alloying and Hot Pressing, Mater. Sci. Eng. A, 2019, 748, p 428–433.

C.X. He, S.Z. Bin, P. Wu, C.D. Gao, P. Feng, Y.W. Yang, L. Liu, Y.Z. Zhou, M.C. Zhao, S. Yang and C.J. Shuai, Microstructure Evolution and Biodegradation Behavior of Laser Rapid Solidified Mg-Al-Zn Alloy, Metals, 2017, 7(3), p 105–116.

H. Men and Z. Fan, Effects of Solute Content on Grain Refinement in an Isothermal Melt, Acta Mater., 2011, 59(7), p 2704–2712.

Y. Ali, D. Qiu, B. Jiang, F.S. Pan and M.X. Zhang, Current Research Progress in Grain Refinement of Cast Magnesium Alloys: A Review Article, J. Alloy. Compd., 2015, 619, p 639–651.

L. Du, Effect of Rare Earth La on the Microstructure and Properties of AZ61 Magnesium Alloy, Nanchang University, Nanchang City, Master’s Thesis (2012)

K.W. Wei, M. Gao, Z.M. Wang and X.Y. Zeng, Effect of Energy Input on Formability, Microstructure and Mechanical Properties of Selective Laser Melted AZ91D Magnesium Alloy, Mater. Sci. Eng. A, 2014, 611, p 212–222.

E. Contreras-Piedras, R. Esquivel-Gonzalez, V.M. López-Hirata, M.L. Saucedo-Muñoz, A.M. Paniagua-Mercado and H.J. Dorantes-Rosales, Growth Kinetics of Cellular Precipitation in a Mg-8.5Al-0.5Zn-0.2Mn (wt.%) Alloy, Mater. Sci. Eng. A, 2010, 527(29–30), p 7775–7778.

L.Y. Jiang, D.F. Zhang, X.W. Fan, F. Guo, G.S. Hu, H.S. Xue and F.S. Pan, The Effect of Sn Addition on Aging Behavior and Mechanical Properties of Wrought AZ80 Magnesium Alloy, J. Alloy. Compd., 2015, 620, p 368–375.

W. Tang, E.H. Han, Y.B. Xu and L. Liu, Effect of Heat Treatment on Microstructure and Properties of AZ80 Magnesium Alloy, Acta Metall. Sin., 2005, 41, p 1199–1206.

K.M. Asl, A. Tari and F. Khomamizadeh, The Effect of Different Content of Al, RE and Si Element on the Microstructure, Mechanical and Creep Properties of Mg-Al Alloys, Mater. Sci. Eng. A, 2009, 523(1–2), p 1–6.

J.F. Archard, Contact and Rubbing of Flat Surfaces, J. Appl. Phys., 1953, 24(8), p 981–988.

A. Kumar, G.K. Meenashisundaram, V. Manakari, G. Parande and M. Gupta, Lanthanum Effect on Improving CTE, Damping, Hardness and Tensile Response of Mg-3Al Alloy, J. Alloy. Compd., 2017, 695, p 3612–3620.

Acknowledgments

This research was funded by the State Key Laboratory of Advanced Processing and Recycling of Non-ferrous Metals, Lanzhou University of Technology [Grant No. SKLAB02014006]; the Suzhou Science and Technology Bureau [Grant No. SYG201642]; the open fund for Jiangsu Key Laboratory of Advanced Manufacturing Technology [Grant No. HGAMTL-1701]; and the Jiangsu province 333 talent Project [Grant No. BRA2017098].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, X., Chen, C. & Zhang, M. Effect of Heat Treatment on Microstructure and Micro-Wear Resistance of Selective Laser Melted Mg-Al-Zn Alloy with La2O3 Addition. J. of Materi Eng and Perform 30, 2316–2328 (2021). https://doi.org/10.1007/s11665-021-05516-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05516-7