Abstract

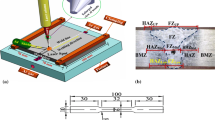

An attempt has been made to join high carbon alloy steel sheet of 0.9 mm thickness by pulse Nd:YAG laser beam welding. Weld melt-pool geometry (i.e., melting depth and width) and the microstructure of the weld zone was analyzed through the optical microscopic images. The tensile strength of the weld joint was assessed through a universal testing machine. The variation of microhardness value in the melt pool zone of the weldment was assessed through Vickers micro indentation method. The effect of laser peak power and scan speed on the melt pool geometry, microstructure, tensile strength, and microhardness value of the weld joint was explored. The outcomes indicated that within the experimental domain for an optimum processing condition (laser peak power: 5 kW, beam diameter: 0.7 mm, pulse duration: 7 ms, and pulse frequency: 5 Hz), full penetrated welding was achieved, which exhibited almost 85% of the base material strength.

Similar content being viewed by others

References

Chung Y D, Fujii H, Ueji R and Tsuji N 2010 Friction stir welding of high carbon steel with excellent toughness and ductility. Scripta Materialia 63: 223–226

Wang L, Wei Y, Zhan X, Yu F, Cao X, Gu C and Ou W 2017 Simulation of dendrite growth in the laser welding pool of aluminum alloy 2024 under transient conditions. Journal of Materials Processing Technology 246: 22–29

Liu S, Mi G, Yan F, Wang C and Jiang P 2017 Correlation of high power laser welding parameters with real weld geometry and microstructure. Optics & Laser Technology 94: 59–67

Ragavendran M, Chandrasekhar N, Ravikumar R, Saxena R, Vasudevan M and Bhaduri A K 2017 Optimization of hybrid laser – TIG welding of 316LN steel using response surface methodology (RSM). Optics and Lasers in Engineering 95: 17–25

Hu Y, He X, Yu G and Zhao S 2017 Capillary convection in pulsed – butt welding of miscible dissimilar couple. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science 231: 2429–2440

Gao X-L, Zhang L-J, Liu J and Zhang J-X 2014 Effects of weld cross-section profiles and microstructure on properties of pulsed Nd:YAG laser welding of Ti6Al4V sheet. The International Journal of Advanced Manufacturing Technology 72: 895–903

Al-Kazzaz H, Medraj M, Cao X and Jahazi M 2008 Nd:YAG laser welding of aerospace grade ZE41A magnesium alloy: Modeling and experimental investigations. Materials Chemistry and Physics 109: 61–76

Tuissi A, Besseghini S, Ranucci T, Squatrito F and Pozzi M 1999 Effect of Nd-YAG laser welding on the functional properties of the Ni-49.6at.%Ti. Materials Science and Engineering A 273–275: 813–817

Akbari Mousavi S A A and Niknejad S T 2009 An Investigation on Microstructure and Mechanical Properties of Nd:YAG Laser Beam Weld of Copper Beryllium Alloy. Metallurgical and Materials Transactions A 40: 1469–1478

Montazeri M and Ghaini F M 2012 The liquation cracking behavior of IN738LC superalloy during low power Nd:YAG pulsed laser welding. Materials characterization 67: 65–73

Tzeng Y, 2000 Parametric analysis of the pulsed Nd:YAG laser seam-welding process Journal of Materials Processing Technology 102: 40–47

Vedani M, 2004 Microstructural evolution of tool steels after Nd-YAG laser repair welding. Journal of materials science 39: 241–249

Ghaini F M, Hamedi M, Torkamany M, and Sabbaghzadeh J, 2007 Weld metal microstructural characteristics in pulsed Nd: YAG laser welding. Scripta Materialia 56: 955–958

Khan M M A, Romoli L, Fiaschi M, Sarri F and Dini G 2010 Experimental investigation on laser beam welding of martensitic stainless steels in a constrained overlap joint configuration. Journal of Materials Processing Technolog 210: 1340–1353

Junaid M, Cheema T A, Haleem H, Saad-ul-Fatah, Rahman K and Park C W, 2019 Effects of thermal material properties on precision of transient temperatures in pulsed laser welding of Ti6Al4V alloy. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science 233: 3170–3181

Sufizadeh A R and Akbari Mousavi S A A, 2017 Microstructures and mechanical properties of dissimilar Nd:YAG laser weldments of AISI4340 and AISI316L steels. International Journal of Minerals, Metallurgy, and Materials 24: 538–549

Lapsanska H, Chmelickova H and Hrabovsky M, 2010 Effect of Beam Energy on Weld Geometric Characteristics in Nd:YAG Laser Overlapping Spot Welding of Thin AISI 304 Stainless Steel Sheets. Metallurgical and materials transactions B 41: 1108–1115

Ventrella V A, Berretta J R and De Rossi W, 2010 Pulsed Nd:YAG laser seam welding of AISI 316L stainless steel thin foils. Journal of Materials Processing Technology 210: 1838–1843

Wu D J, Ma G Y, Niu F Y and Guo D M, 2013 Pulsed Laser Welding of Hastelloy C-276: High-Temperature Mechanical Properties and Microstructure. Materials and manufacturing processes 28: 524–528

Pakmanesh M R and Shamanian M, 2018 Optimization of pulsed laser welding process parameters in order to attain minimum underfill and undercut defects in thin 316L stainless steel foils. Optics & Laser Technology 99: 30–38

Kumar N, Mukherjee M, Bandyopadhyay A 2017 Study on laser welding of austenitic stainless steel by varying incident angle of pulsed laser beam. Optics & Laser Technology 94: 296–309

Balajaddeh M B and Naffakh-Moosavy H 2019 Pulsed Nd: YAG laser welding of 17-4 PH stainless steel: Microstructure, mechanical properties, and weldability investigation. Optics & Laser Technology 119: 105651

Geng Y, Akbari M, Karimipour A, Karimi A, Soleimani A and Afrand M, 2019 Effects of the laser parameters on the mechanical properties and microstructure of weld joint in dissimilar pulsed laser welding of AISI 304 and AISI 420. Infrared Physics & Technology 103: 103081

Ebrahimzadeh H and Mousavi S A A A 2012 Investigation on pulsed Nd:YAG laser welding of 49Ni–Fe soft magnetic alloy. Materials & Design 38: 115–123

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sahoo, C.K., Mallick, S., Kumar, K. et al. Pulse laser welding of high carbon alloy steel: assessment of melt pool geometry and mechanical performance. Sādhanā 46, 13 (2021). https://doi.org/10.1007/s12046-020-01528-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-020-01528-6