Abstract

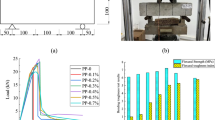

Fiber reinforced concrete (FRC) has been used for many different construction applications and many testing protocols have been developed to determine their mechanical behavior. The present paper focus on the comparisons between four major mechanical tests used for FRC: EN 14651, ASTM 1609, ASTM 1550 and EN 14488. Polypropylene fibers were used as reinforcement in volume ratios of 3 kg/m3, 6 kg/m3 and 10 kg/m3 in a self-consolidating high-strength concrete. The flexural beam tests according to ASTM 1609 and EN 14651 standards were carried on through a closed loop type of control. Comparisons include crack post-peak strength and energy absorption values. The EN 14651 showed to be more precise for low ductile concretes (i.e., low fiber volume fractions). This is due to the notch in the EN standard and different methods used for instrumenting the specimen. The EN 14488 due to its boundary conditions showed much higher results with a deflection-hardening type of behavior. Since the EN 14488’s frame comes into full contact with the specimen, that creates a more rigid material response. This response differs from the other three tests since their support conditions allow rotations and induces cracks to appear in determined locations.

Similar content being viewed by others

References

Alsalman A, Dang CN, Prinz GS, Hale WM (2017) Evaluation of modulus of elasticity of ultra-high performance concrete. Construction and Building Materials 153:918–928, DOI: https://doi.org/10.1016/j.conbuildmat.2017.07.158

Aly T, Sanjayan JG, Collins F (2008) Effect of polypropylene fibers on shrinkage and cracking of concretes. Materials and Structures 41(10): 1741–53, DOI: https://doi.org/10.1617/s11527-008-9361-2

ASTM C1399/C1399M-10 (2015) Standard test method for obtaining average residual-strength of fiber-reinforced concrete. ASTM C1399/C1399M-10, American Society for Testing and Materials International, West Conshohocken, PA, USA

ASTM C1550 (2012) Standard test method for flexural toughness of fiber reinforced concrete (using centrally loaded round panel). ASTM C1550, American Society for Testing and Materials International, West Conshohocken, PA, USA

ASTM C1609/C1609M (2012) Standard test method for flexural performance of fiber-reinforced concrete (using beam with third-point loading). ASTM C1609/C1609M, American Society for Testing and Materials International, West Conshohocken, PA, USA

ASTM C1765-18 (2018) Standard specification for steel fiber reinforced concrete culvert, storm drain, and sewer pipe. ASTM C1765-18, American Society for Testing and Materials International, West Conshohocken, PA, USA

ASTM C1812/C1812M-15e1 (2015) Standard practice for design of journal bearing supports to be used in fiber reinforced concrete beam tests. ASTM C1812/C1812M-15e1, American Society for Testing and Materials International, West Conshohocken, PA, USA

Banthia N, Trottier JF (1995) Test methods for flexural toughness characterization of fiber reinforced concrete: Some concerns and proposition. ACI Materials Journal 92:48–57

Bentur A, Mindess S (2007) Fiber reinforced cementitious composites, 2nd edition. Taylor & Francis, London, UK

Bernard E, Dean SW (2009) Influence of test machine control method on flexural performance of fiber reinforced concrete beams. Journal of ASTM International 6(9):3–11, DOI: https://doi.org/10.1520/JAI102327

Bernard E, Pircher M (2001) The influence of thickness on performance of fiber-reinforced concrete in a round determinate panel test. Cement, Concrete and Aggregates 23(1):27–33, DOI: https://doi.org/10.1520/CCA10522J

Buratti N, Mazzotti C, Savoia M (2011) Post-cracking behaviour of steel and macro-synthetic fibre-reinforced concretes. Construction and Building Materials 25(5):2713–2722, DOI: https://doi.org/10.1016/j.conbuildmat.2010.12.022

CEB-FIP (2012) Model code 2010. CEB-FIP, Federation Internationale du Beton, International Federation for Structural Concrete, Lausanne, Switzerland

Cifuentes H, García F, Maeso O, Medina F (2013) Influence of the properties of polypropylene fibres on the fracture behavior of low-, normal- and high-strength FRC. Construction and Building Materials 45:130–137, DOI: https://doi.org/10.1016/j.conbuildmat.2013.03.098

Conforti A, Minelli F, Plizzari GA, Tiberti G (2017a) Comparing test methods for the mechanical characterization of fiber reinforced concrete. Structural Concrete 19(3):656–669, DOI: https://doi.org/10.1002/suco.201700057

Conforti A, Tiberti G, Plizzari GA, Caratelli A, Meda A (2017b) Precast tunnel segments reinforced by macro-synthetic fibers. Tunnelling and Underground Space Technology 63:1–11, DOI: https://doi.org/10.1016/j.tust.2016.12.005

de Larrard F (1999) Concrete mixture-proportioning - A scientific approach. E & FN SPON, London, UK

di Prisco M, Plizzari G, Vandewalle L (2009) Fiber reinforced concrete: New design perspectives. Materials and Structures 42:1261–1281, DOI: https://doi.org/10.1617/s11527-009-9529-4

EFNARC (1996) European specification for sprayed concrete. European Federation of Producers and Applications of Specialist Products for Structures, Loughborough University, Loughborough, UK, 8–10

EN 14488-5 (2006) Testing sprayed concrete - Part 5: Determination of energy absorption capacity of fiber reinforced slab specimens. EN 14488-5, Europe Standard, Brussels, Belgium

EN 14651 (2005) Test method for metallic concrete - Measuring the flexural tensile strength (limit of proportionality (LOP), residual). EN 14651, European Committee for Standardization, Brussels, Belgium

Fallah S, Nematzadeh M (2017) Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Construction Builduiding Materials 132:170–187, DOI: https://doi.org/10.1016/j.conbuildmat.2016.11.100

Gettu R, Mobasher B, Carmona S, Jansen DC (1996) Testing of concrete under closed-loop control. Advanced Cement Based Materials 3:54–71, DOI: https://doi.org/10.1016/S1065-7355(96)90072-3

Han S, Lee S, Lee J (2010) The flexural toughness of round plastic fiber reinforced shotcrete specimens with ring-supports. Korea Concrete Institute, Seoul, Korea, 733–738

Hesami S, Hikouei IS, Emadi SAA (2016) Mechanical behavior of self-compacting concrete pavements incorporating recycled tire rubber crumb and reinforced with polypropylene fiber. Journal of Cleaner Production 133:228–234, DOI: https://doi.org/10.1016/j.jclepro.2016.04.079

JCISF4 (1994) Method of tests for flexural strength and flexural toughness of fiber reinforced concrete. JCISF4, Japan Concrete Institute, Tokyo, Japan

JSCE-G 552 (2013) Test method for bending strength and bending toughness of steel fiber reinforced concrete. JSCE-G 552, Japan Society of Civil Engineers, Tokyo, Japan

Kim DJ, Naaman AE, El-Tawil S (2008) Comparative flexural behavior of four fiber reinforced cementitious composites. Cement & Concrete Composites 30:917–928, DOI: https://doi.org/10.1016/j.cemconcomp.2008.08.002

Link RE, Banthia N, Mindess, S (2004) Toughness characterization of fiber-reinforced concrete: Which standard to use? Journal of Testing and Evaluation 32(2), DOI: https://doi.org/10.1520/JTE11901

Malhota VM, Carette GG, Bilodeau A (1994) Mechanical properties and durability of polypropylene fiber reinforced high-volume fly ash concret for shotcrete applications. American Concrete Institute Materials Journal 1994:91(5):478–86

Minelli F and Plizzari G. (2009) Round panel vs. beam tests toward a comprehensive and harmonic characterization of FRC materials. In: Brittle matrix composites 9, Woodhead Publishing, Cambridge, UK, 23–32, DOI: https://doi.org/10.1533/9781845697754.23

Mitchell MR, Link RE, Minelli F, Plizarri G (2011) A new round panel test for the characterization of fiber reinforced concrete: A broad experimental study. Journal of Testing and Evaluation 39(5), DOI: https://doi.org/10.1520/JTE103392

Naaman AE (1987) High performance fiber reinforced cement composites: Classification and applications. Proceedings of the IABSE symposium on concrete structures for the future, Paris, France

Navas FO, Navarro-Gregori J, Herdocia GL, Serna P, Cuenca E (2018) An experimental study on the shear behaviour of reinforced concrete beams with macro-synthetic fibres. Construction and Building Materials 169:888–899, DOI: https://doi.org/10.1016/j.conbuildmat.2018.02.023

Olivito RS, Zuccarello FA (2010) An experimental study on the tensile strength of steel fiber reinforced concrete. Composites: Part B 41:246–255, DOI: https://doi.org/10.1016/j.compositesb.2009.12.003

Parmentier B, Vandewalle L, Van Rickstal F (2008) Evaluation of the scatter of the postpeak behaviour of fibre reinforced concrete in bending: A step toward reliability. Proceedings of 7th international RILEM symposium on fibre reinforced concrete: Design and applications, September 17–19, Chennai, India, 133–143

Pereira E (2017) Influência de fibras de aço no comportamiento mecânico e nos mecanismos de fissuração de concretos auto adensáveis. MSc Thesis, Pontifícia Universidade Católica do Rio de Janeiro (PUC-Rio), Rio de Janeiro, Brazil

Plizzari GA, Tiberti G (2006) Structural behavior of SFRC tunnel segments. Tunneling and Underground Space Technology 21:438–439

Rambo DAS (2012) Concretos autoadensáveis reforçados com fibras de aço híbridas: Aspectos materiais e estruturais. MSc Thesis, Universidade Federal do Rio de Janeiro, UFRJ, Rio de Janeiro, Brazil

Rambo DAS, Blanco A, de Figueiredo AD, dos Santos ERF, Toledo RD, Gomes OFM (2018) Study of temperature effect on macrosynthetic fiber reinforced concretes by means of Barcelona tests: An approach focused on tunnels assessment. Construction and Building Materials 158:443–453, DOI: https://doi.org/10.1016/j.conbuildmat.2017.10.046

Rooholamini H, Hassani A, Aliha MRM (2018) Evaluating the effect of macro-synthetic fibre on the mechanical properties of roller-compacted concrete pavement using response surface methodology. Construction and Building Materials 159:517–529, DOI: https://doi.org/10.1016/j.conbuildmat.2017.11.002

Serafini R, Dantas SRA, Salvador RP, Agra RR, Rambo DAS, Berto AF, de Figueiredo AD (2019) Influence of fire on temperature gradient and physical-mechanical properties of macro-synthetic fiber reinforced concrete for tunnel linings. Construction and Building Materials 214:254–268, DOI: https://doi.org/10.1016/j.conbuildmat.2019.04.133

Sorelli L, Meda A, Plizzari GA (2005) Bending and uniaxial tensile tests on concrete reinforced with hybrid steel fibers. Journal of Materials in Civil Engineering 17(5):519–527, DOI: https://doi.org/10.1061/(ASCE)0899-1561(2005)17:5(519)

Tiberti G, Minelli F, Plizzari G, Vecchio FJ (2014) Influence of concrete strength on crack development in SFRC members. Cement & Concrete Composites 45:176–185, DOI: https://doi.org/10.1016/j.cemconcomp.2013.10.004

Vandewalle L, Van Rickstal F, Heirman G, Parmentier B (2008) The round panel test and the 3-point bending test. 7th RILEM international symposium on fibre reinforced concrete: Design and applications BEFIB, September 17–19, Chennai, India

Yew MK, Mahmud HB, Ang BC, Yew MC (2015) Influence of different types of polypropylene fibre on the mechanical properties of high-strength oil palm shell lightweight concrete. Construction and Building Materials 90:36–43, DOI: https://doi.org/10.1016/j.conbuildmat.2015.04.024

Zhao O, Yu J, Geng G, Jiang J, Liu X (2016) Effect of fiber types on creep behaviour of concrete. Construction and Building Materials 105:416–422, DOI: https://doi.org/10.1016/j.conbuildmat.2015.12.149

Zia A, Ali M (2017) Behavior of fiber reinforced concrete for controlling the rate of cracking in canal-lining. Construction and Building Materials 155:726–739, DOI: https://doi.org/10.1016/j.conbuildmat.2017.08.078

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Manfredi, R.P., de Andrade Silva, F. Test Methods for the Characterization of Polypropylene Fiber Reinforced Concrete: A Comparative Analysis. KSCE J Civ Eng 24, 856–866 (2020). https://doi.org/10.1007/s12205-020-0741-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12205-020-0741-7