Abstract

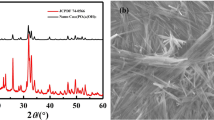

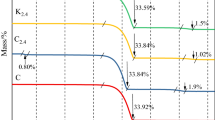

In spite of the advantages of CaO refractories, such as high refractoriness, potential to produce pure steel molten, and high alkaline corrosion resistance, their application has been limited due to its poor hydration resistance. Introducing additives to improve the hydration resistance of lime is a novel method. The influences of Mg(OH)2 and sintering temperatures on the sintering and hydration resistance of CaO aggregates that were produced by thermal decomposition were investigated in this paper. The purpose of this work was to produce high-purity CaO raw material with high density, low porosity, well grain growth, and good hydration resistance economically. The sintered samples were characterized by bulk density, apparent porosity, surface appearance, and microstructure. The results indicated that (1) Mg(OH)2 promoted the grain growth of CaO, reduced the apparent porosity, and improved the density of the specimens. The hydration resistance of the samples was increased. (2) Increasing the sintering temperature improved the hydration resistance of the specimens obviously in the experiment. (3) Grain size of CaO was more uniform with the increment of Mg(OH)2 content, and the density of the compacts was improved.

Similar content being viewed by others

References

Stendera, J.W., Riedl, J.R.: Recent experience with dolomite in large steel ladles. Iron and Steelmaker. 13, 3): 1–3):23 (1956)

Tindyala, M.A., Brown Jesse, J.: Dolomite ladle refractories at inland steels no.1ElectricFurnace shop. Iron and Steelmaker. 12(11), 44–45 (1985)

Kijac, J., Kovac, P., Steranka, E., et al.: The current status of tundish covering slags in a slab caster plant. Metalurgija. 43(1), 59–62 (2004)

Zhao-you, C., Shou-xin, T.: Relationship between clean steel and refractories. Refractories. 38(4), 219–225 (2004)

Wei, Y.W., Li, N.: Refractories for clean steelmaking. Am. Ceram. Soc. Bull. 81(5), 32–35 (2002)

Chengxun, W., Yongjie, L.: Refractories for Secondary Steelmaking Process, vol. 137. Metallurgical Industry Press, Beijing (1996)

Xiang-chong, Z.: Looking ahead—a new generation of high performance refractory ceramics. Refractories. 37(1), 1–10 (2003)

Oda, Y.: Preventives methods for hydration of calcia and dolomite clinker. Taikabutsu. 41(12), 690–700 (1989)

Chen, M., Ito, S., Yamaguchi, A.: Carbonation of CaO clinkers and improvement of their hydration resistance. Ceram Soc Japan. 110(6), 512–517 (2002)

Lee, J.K., Choi, H.S., Lee, S.J.: Effect of Fe2O3 additions on the hydration resistance of CaO. J. Ceram. Process. Res. 13(5), 646–650 (2012)

Ghasemi-Kahrizsangi, S., Nemati, A., Shahraki, A., et al.: Densification and properties of Fe2O3 nanoparticles added CaO refractories. Ceram. Int. 42(10), 12270–12275 (2016)

Ghosh, A., Bhattacharya, T.K., Mukherjee, B., et al.: The effect of CuO addition on the sintering of lime. Ceram. Int. 27(2), 201–204 (2001)

Ghosh, A., Bhattacharya, T.K., Maiti, S., et al.: Densification and properties of lime with V2O5 additions. Ceram. Int. 30(8), 2117–2120 (2004)

Chen, G., Li, B., Zhang, H., et al.: On the modification of hydration resistance of CaO with ZrO2 additive. Int. J. Appl. Ceram. Technol. 13(6), 1173–1181 (2016)

Bhattacharya, T.K., Ghosh, A., Tripathi, H.S., et al.: Solid state sintering of lime in presence of La2O3, and CeO2. Bull. Mater. Sci. 26(7), 703–706 (2003)

Moorkah, H.I., Abolarin, M.S.: Investigation of the properties of locally available dolomite for refractory applications, Niger. J. Technol. 24(1), 79–86 (2005)

Ghasemi-Kahrizsangi, S., Barati Sedeh, M., Gheisari Dehsheikh, H., et al.: Densification and properties of ZrO2 nanoparticles added magnesia–doloma refractories. Ceram. Int. 2016, S0272884216310744

Qiu, G.-B., Peng, B., et al.: Properties of regenerated MgO–CaO refractory bricks: impurity of iron oxide[J]. Ceram. Int. 42(2), 2933–2940 (2016)

Othman, A.G.M., El-Maaty, M.A.A., Serry, M.A.: Hydration-resistant lime refractories from Egyptian limestone and ilmenite raw materials. Ceram. Int. 27(7), 801–807 (2001)

Liu, P.: Foundation of Crystal Defect, pp. 242–243. Science Press, Beijing (2010)

Khlebnikova, Y., Zhukovskaya, A.E., Seliovanova, A.N.: Methods for determining hydration resistance of refractories. J. Refract Ind. Ceram. 48, 2–6 (2007)

Zhang, H., Zhao, H., Zhen, J., Yu, J., Nie, J.: Defect study of MgO–CaO material doped with CeO2. J. Adv. Mater. Sci. Eng. 20, 1–5 (2013)

Han, Z., huizhong, Z., et al.: Defect study of MgO—CaO material doped with CeO2. Functional Materials. 44(16), 2343–2347 (2013)

Kingery, W.D.: Introduction to Ceramics, pp. 353–370. John Wiley and Sons Inc, New York (1960)

Yin, H., Ma, Y., Yan, J.: Effect of MgO coating on the hydration resistance of MgO-CaO clinkers. J Mater Sci Forum. 695, 324–327 (2011)

Zhilin, Z., Weiming, G., Yang, Y., Shanghua, W.: Effects of sintering temperature and composite additive on microstructure and properties of Al2O3-TiCN ceramics. Mater. Mech.l Eng. 2015(10), 47–51

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, T., Wei, Y., Chen, J. et al. Effect of Mg(OH)2 and sintering temperature on the hydration resistance of CaO aggregate by thermal decomposition. J Aust Ceram Soc 56, 795–801 (2020). https://doi.org/10.1007/s41779-019-00399-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-019-00399-3