Abstract

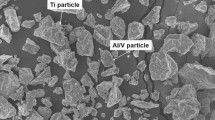

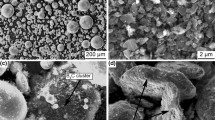

A new approach to powder processing is employed in forming titanium aluminide composites. The processing consists of internal heating of a customized powder blend by a fast electrical discharge of a homopolar generator. The high-energy high-rate “1MJ in 1s” pulse permits rapid heating of an electrically conducting powder mixture in a cold wall die. This short time at temperature approach offers the opportunity to control phase transformations and the degree of microstructural coarsening not readily possible with standard powder processing approaches. This paper describes the consolidation results of titanium aluminide-based powder composite materials. The focus of this study was the definition of microstructure/processing relationships for each of the composite constituents, first as monoliths and then in composite forms. Non-equilibrium phases present in rapidly solidified TiAl powders are transformed to metastable intermediates en route to the equilibrium gamma phase. The initial single phase beta in Nb-stabilized Ti3Al is transformed to alpha two with an intermediate beta two phase. In composite blends of TiAl powders mixed with Nb-stabilized Ti3Al powders a 10 μm thick interfacial layer is formed on the dispersed TiAl. Limited control of post-pulse heat extraction prevents full retention of the rapidly solidified powder microstructures.

Similar content being viewed by others

References

Joanne L. Murray, Met. Trans. 19A, 243 (1988).

S. H. Whang, Z. X. Li, and D. Vujic in High-Temperature Ordered Intermetallic Alloys II, edited by N. S. Stoloff, C. C. Koch, C. T. Liu, and O. Izumi ( Mater. Res. Soc. Proc. 81, Pittsburgh, PA 1987) pp. 151 - 156.

S. C. Huang, E. L. Hall, and M. F. X. Gigliotti in High-Temperature Ordered Intermetallic Alloys II, op. cit., pp. 481 - 486.

R. Strychor, J. C. Williams, and W. A. Soffa, Met. Trans. 19A, 225 (1988).

H. A. Lipsitt, in High-Temperature Ordered Intermetallic Alloys, edited by C. C. Koch et. al., ( Mater. Res. Soc. Proc. 39, Pittsbuigh, PA 1985) pp. 351 - 364.

H. A. Lipsitt, in Advanced High-Temperature Al oys: Processing and Properties, edited by S. M. Allen et al.(ASM, Ohio, 1986) pp.157 - 164.

M. E. Fine, D. L. Bourell, Z. Eliezer, C. Persad and H. L. Marcus, Scripta Metallurgics 22, 907 (1986).

J. C. Williams, in Precipitation Processes in Solids. K. C. Russell and H. I. Aaronson, eds., (TMS-AIME, Warrendale, 1978) p. 191.

H. L. Marcus, D. L. Bourell, Z. Eliezer, C. Persad and W. F. Weldon, Journal of Metals, 39, 6 (December 1987).

G.Elkabir, L. Rabenberg, C.Persad and H.L.Marcus, Scripta Met. 20, 1411 (1986).

D. R. Ervin, D. Bourell, C. Persad, L. Rabenbeig, J. Mat. Sci. Eng. A102, 25 (1988).

C.E. Price in Metals Handbook, 9th. edition. V. 9. Metallography and Microstructures (ASM, Metals Park, OH, 1985) p. 151.

H. W. Rosenberg and W. D. Nix, Met. Trans. 12, 2962(1970).

P. R. Bridenbaugh, F. R. Billman, W. S. Cebulal, and G. J. Hildeman, in Advanced High-Temperature Alloys: Processing and Properties, op. cit., pp. 53-64.

M. J. Blackburn and M. P. Smith, U. S. Patent No. 4 292 077 ( 29 September 1981).

C. -J. Hou et al., presented at the 1988 TMS/AIME Fall Meeting, Chicago, IL, 1988.

A. G. Jackson, K. Teal and F. H. Froes in High Temperature Ordered Intermetallic Alloys II, op. cit., pp. 143 -149.

D. Banerjee, A. K. Gogia, T. K. Nandi and V. A Joshi, Acta Metall. 36, 871 (1988).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Persad, C., Lee, BH., Hou, CJ. et al. Microstructure/Processing Relationships in High-Energy High-Rate Consolidated Powder Composites of Nb-Stabilized Ti3Al + TiAl. MRS Online Proceedings Library 133, 717 (1988). https://doi.org/10.1557/PROC-133-717

Published:

DOI: https://doi.org/10.1557/PROC-133-717