Abstract

Investigations of the shape memory effect in alloys forming thermoelastic martensites with various crystal structures (2H, 3R, 9R and 18R) reveal that universal behavior exists. A unified explanation of the martensite deformation processes and subsequent shape recovery is now in hand, even though the various martensites are both internally twinned and internally faulted and, in addition, have different crystal structures. In cases studied to date, an initial parent phase single crystal transforms into self-accommodating arrangements of martensite variants (plates) which are characterized by “plate groups.” Each group consists of four variants. The average shape deformation in a plate group is essentially zero.

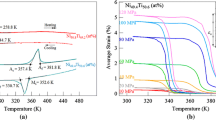

Upon stressing below the Mf temperature the martensite undergoes deformation by detwinning (2H and 3R only), variant-variant coalescence and twinning processes, and further group-to-group coalescence. The deformed specimen eventually becomes a single crystal of martensite consisting of that particular habit plane variant whose shape deformation permits maximum extension in the direction of the applied stress. The deformed martensite persists after unloading has occurred; reverse rearrangements of twins and variants do not occur. Specimens deformed below Mf regain their initial shape characteristic of the initial parent phase upon heating from As to Af, during which the single crystal of martensite obtained by stressing the 24-variant configuration transforms back to the original parent phase single crystal in a unique manner, which is basically a simple “unshearing” process. The unshearing is the essence of the memory.

The two-way shape memory effect results after the initial martensitic transformation upon cooling is preprogrammed by the introduction of stresses which preferentially bias the transformation so that only a single variant of martensite forms upon cooling. The shape change of this single variant causes the characteristic spontaneous “bending” upon cooling. The characteristic “unbending upon heating is as with the conventional “one-way” shape memory effect.

Similar content being viewed by others

References

C.M. Jackson, H. J. Wagner, and R. J. Wasilewski, NASA Report SP-5100 (1972).

K. Shimizu and C. M. Wayman, Metal Science Journal 6, 175 (1972).

L. Oelaey, R. V. Krishnan, H. Tas, and H. Warlimont, J. Mat. Sci. 9, 1521, 1536, 1545 (1974).

J. Perkins (ed.), Shape Memory Effects in Alloys (Plenum Press, New York 1976).

Raychem Corporation, Menlo Park, CA, Advertising Brochures ME-002 and ME-008, and other leaflets.

L. M. Schetky, Proc. Intl. Conf. on Martensitic Transformations, ICOMAT-79, Cambridge, MA, 693 (June 24–29, 1979).

Foxboro Company Foxboro, MA, Technical Information Sheet TI 220–160 (December 1973).

W. J. Buehler and W. B. Cross, Wire Journal 2, 41 (1969).

H. C. Tong and C. M. Wayman, Met. Trans. 6A, 29 (1975).

P. N. Sawyer, M. Page, L. Baseliust, C. McCool, E. Lester, B. Stanczewski, S. Srinivasan, and N. Ramasamy, Bull, of Texas Heart Inst. 3, No 1, 65 (1976).

M. Simon, R. Kaplow, E. Salzman, and D. Freiman, Radiology 125, No. 1, 89 (1977).

N. Netsu, T. Iwabuchi and T. Honma, Bull. Res. Inst, of Mineral Dressing and Metallurgy, Tohoku University 34 (1978), 62 (in Japanese).

M. A. Schmerling M. A. Wilkov, A. E. Sanders, and J. E. Woosley in: Shape Memory Effects in Alloys (Plenum Press, New York 1975), p. 563.

J. Hughes, Orthopedics Department, University of Mississippi, Jackson, MS, private communication (1979).

G. F. Andreasen and R. E. Morros, American Journal of Orthodontics 73, No. 2, 142 (1978).

Unitek Corporation, Monrovia, CA, Nitinol “Activ-Arch,” Brochure 16–373 (1979).

T. A. Schroeder, I. Cornell’s, and C. M. Wayman, Met. Trans. 7A, 535 (1976).

T. A. Schroeder and C. M. Wayman, Acta Met 25, 1375 (1977).

L. Delaey and H. Warlimont, Progress in Matls. Sci. Vol. 18 (Pergamon Press, Oxford 1974).

T. Saburi and C. M. Wayman, Acta Met. 27, 979 (1979).

T. Saburi, C.M. Wayman, T. Takata and S. Nenno, Acta Met. 28, 15 (1980).

T. Saburi and C. M. Wayman, Acta Met. 28, 1 (1980).

K. Otsuka and K. Shimizu, Trans. JIM 15, 109 (1974).

K. Otsuka and K. Shimizu, Scripta Met. 11, 757 (1977).

T. A. Schroeder and C. M. Wayman, Scripta Met. 11, 225 (1977).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wayman, C.M. Thermoelastic Martensitic Transformations and the Nature of the Shape Memory Effect. MRS Online Proceedings Library 21, 657–667 (1983). https://doi.org/10.1557/PROC-21-657

Published:

Issue Date:

DOI: https://doi.org/10.1557/PROC-21-657