Abstract

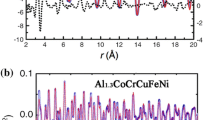

There exist large amounts of experimental evidence on stress relaxation for metals and their alloys, synthetic and natural polymers, glasses and frozen non-polymeric organic liquids. The results, typically presented as curves σ (log t) of relaxation of stress σ as a function of logarithmic time t, exhibit common features, apparently independent of the type of material. All curves consist of three regions: initial, nearly horizontal, starting at σ0; central, descending approximately linearly; and final, corresponding to the internal stress σi = σ(∞). We discuss briefly the experimental evidence as well as the main features of the cooperative theory which does not involve specific features of different classes of materials. The bulk of the paper deals with computer simulations. Simulation results obtained with the method of molecular dynamics are reported for ideal metal lattices, metal lattices with defects, and for polymeric systems. In agreement with both experiments and the cooperative theory, the simulated σ (log t) curves exhibit the same three regions. In agreement with the theory, the slope of the simulated central part is proportional to the initial effective stress σ0* = σ0 − σi,. The time range taken by the central part Is strongly dependent on the defect concentration: the lower the defect concentration, the shorter the range. Imposition in the beginning of a high strain ɛ destroys largely the resistance of a material to deformation, resulting in low values of the internal stress σi. Since the cooperative theory assumes for particles (atoms, polymer chain segments) the existence of two states, unrelaxed and relaxed, and has a formal connection to the Bose-Einstein (B-E) distribution, we first simulate B-E systems, recording the formation of relaxed clusters of particles of different sizes. Differences in cluster sizes predicted from a B-E model and those obtained from the simulations are recorded and analyzed. On the joint basis of experimental, theoretical and simulation results, we explain the mechanism of stress relaxation in terms of deformations occurring in the immediate environment of the defects. These deformations, visible in simulations of both metals and polymers, correspond to cluster relaxations in the cooperative theory, and thus confirm a posteriori the assumptions made in developing the theory.

Similar content being viewed by others

References

V. H. Kenner in Failure of Plastics, edited by W. Brostow and R. D. Corneliussen (Hanser, Munich - Vienna New York, 1986) Chap. 2.

J. Kubát and M. Rigdahl in Failure of Plastics, edited by W. Brostow and R. D. Corneliussen (Hanser, Munich - Vienna New York, 1986) Chap. 4.

J. Kubát, Nature 204, 378 (1965).

J. Kubát, L.-Å. Nilsson and W. Rychwalski, Res Mechanica 5, 309 (1982).

J. C. M. Li, Can. J. Phys. 45, 493 (1967).

W. Brostow, Science of Materials (Wiley, New York, 1979); W. Brostow, Einstieg in die moderne Werkstoffwissenschaft (Carl Hanser, München - Wien, 1985).

J. Kubát, Phys. Status Solidi B 111, 599 (1982).

J. Kubát and M. Rigdahl, Mater. Sci. & Eng. 24, 223 (1976).

J.M. Kubát, J.-F. Jansson, M. Delin, J. Kubát, R.W. Rychwalski and S. Uggla, J. Appl. Phys. 72, 5179 (1992).

W. Brostow and J. Kubát, Phys. Rev. B 47, 7659 (1993).

Z.-G. Wang, U. Landman, R.L. Blumberg Selinger and W.M. Gelbart, Phys. Rev. B. 44, 378 (1991).

F. F. Abraham, Phys. Rev. Letters 44, 463 (1980).

F. F. Abraham, Phys. Rep. 80, 339 (1981).

V. Mom, J. Comput. Chem. 2, 446 (1981).

S. Blonski, W. Brostow and J. Kubát, Phys. Rev. B 49, in press (1994).

D. Srolowitz, V. Vitek and T. Egami, Acta Metall. 31, 335 (1983).

Acknoledgments

Dr. Slawomir Blonski, Mr. Wyatt A. Foard and Mr. James Palmer have participated in programming and in simulation runs. Computations were made on a Digital DecStation 3100 in Stockholm, on a Performance Optimization IBM RISC System/6000 Power Station in Denton, and on a Cray at the National Center for Computing Applications, Urbana, IL. We appreciate discussions with Prof. Robert Maksimov, Institute of Polymer Mechanics of the Latvian Academy of Sciences, Riga and with Prof. Nicholas W. Tschoegl at the California Institute of Technology, Pasadena.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Brostow, W., Kubát, J. & Kubát, M.J. Stress Relaxation in Metals and Polymers: Theory, Experiment and Computer Simulations. MRS Online Proceedings Library 321, 99–106 (1993). https://doi.org/10.1557/PROC-321-99

Published:

Issue Date:

DOI: https://doi.org/10.1557/PROC-321-99