Abstract

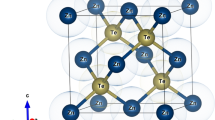

High-resolution transmission electron microscopy, x-ray photoelectron spectroscopy (XPS), and Raman spectroscopy were used to study phase configuration and nanostructure evolutions of Ti–Cx–Ny thin films with different amounts of C incorporation. It was found that the atomic ratio of (C + N)/Ti played a crucial role in phase configuration and nanostructure evolutions as well as mechanical behaviors. When the ratio was less than one unit, a nanocrystalline (nc-) Ti(C, N) solid solution was formed by way of dissolution of C into TiN lattice. When this dissolution reached saturation, precipitation of a small amount of amorphous (a-) C phase along nc-Ti(C, N) grains was followed with more C incorporation. Further increase of C content (up to ∼19 at.% C) made the amorphous phase fully wet nanocrystallites, which resulted in the formation of two-phase nanocomposite thin films with microstructures comprising of ∼5 nm nc-Ti(C,N) crystallites separated by ∼0.5 nm a-(C, CNx) phase. Thicker amorphous walls and smaller sized grains were followed when the C content was further increased, accompanying with the formation of some disorders and defects in nc-grains and amorphous matrices. When the C content was increased to ∼48 at.%, 1–3 nm nanocrystallites with an average size of ∼2 nm were embedded into amorphous matrices. Both microhardness and residual compressive stress values were increased with increase of the atomic ratio in solid solution thin films when the atomic ratio value was less than one unit. Their maximums were obtained at stiochiometry nc-Ti(C,N) solid solution. Enhancement of hardness values was attributed to solid solution effect.

Similar content being viewed by others

References

K. Narasimhan, S.S. Prasad Boppana D.G. Bhat: Development of a graded TiCN coating for cemented carbide cutting tools: A design approach. Wear 188, 123 1995

R. Hauert, J. Patscheider, L. Knoblauch M. Diserens: New coatings by nanostructuring. Adv. Mater. 11, 175 1999

P.H. Mayrhofer, C. Mitterer H. Clemens: Self-organized nanostructures in hard ceramic coatings. Adv. Eng. Mater. 7, 1071 2005

S. Vepřek, G.J. Vepřek-Heijman, M.P. Karvankova J. Prochazkz: Different approaches to superhard coatings and nanocomposite. Thin Solid Films 476, 1 2005

D.J. Cheng, W.P. Sun M.H. Mon: The morphology and structure of chemical vapor deposited Ti(C, N) coating. Thin Solid Films 146, 45 1987

Y.H. Lu, Z.J. Liu Y.G. Shen: Investigation of nanostructure evolution and deformation of nanocrystallite in Ti–Bx–Ny nanocomposite thin films by HRTEM and Monte Carlo simulation. Acta Mater. 54, 2897 2006

M.J. Demkowicz A.S. Argon: High-density liquidlike component facilitates plastic flow in a model amorphous silicon system. Phys. Rev. Lett. 93, 025505 2004

S. Vepřek, P. Nesládek, A. Niederhofer, F. Glatz, M. Jílek M. Šíma: Recent progress in the superhard nanocrystalline composites: Towards their industrialization and understanding of the superhardness. Surf. Coat. Technol. 108–109, 138 1998

L. Karlsson, L. Hultman, J.E. Sundgen L. Karlsson: Influence of residual stresses on the mechanical properties of TiCxNt−x (x = 0, 0.15, 0.45) thin films deposited by arc evaporation. Thin Solid Films 371, 167 2000

S.H. Jhi, J. Ihm, S.G. Louie M.L. Cohen: Electric mechanism of hardness enhancement in transition-metal carbonitrides. Nature 399, 132 1999

D.G. McCulloch, S. Prawer A. Hoffman: Structural investigation of xenon-ion-beam-irradiated glassy carbon. Phys. Rev. B 50, 5905 1994

C.A. Carrasco, S.V. Vergara, G.R. Benavente, N. Mingolo J.C. Rios: The relationship between residual stress and process parameters in TiN coatings on copper alloy substrates. Mater. Character. 48, 81 2002

J.E. Sundgren, A. Rockett J.E. Greene: Microstructural and microchemical characterization of hard coatings. J. Vac. Sci. Technol., A 4, 2770 1986

L. Hultman: Thermal stability of nitride thin films. Vacuum 57, 1 2000

J.G. Naeini, B.M. Way, J.R. Dahn J.C. Irwin: Raman scattering from boron substituted carbon films. Phys. Rev. B 54, 144 1996

A.C. Ferrari: Determination of bonding in diamond-like carbon by Raman spectroscopy. Diamond Relat. Mater. 11, 1053 2002

R.O. Dillon, J.A. Woollan V. Katanata: Use of Raman scattering to investigate disorder and crystallite formation in as-deposited and annealed carbon films. Phys. Rev. B 29, 3482 1984

M.F. Hochella, J.R. Lindsay, V.G. Mossotti C.M. Eggleston: Sputter depth profiling in mineral-surface analysis. Amer. Miner. 73, 1449 1988

L.G. Cancado, K. Takai, T. Enoki, M. Endo, Y.A. Kim, H. Mizusaki, A. Jorio, L.N. Coelho, R. Magalháes-Paniago M.A. Pimenta: General equation for the determination of the crystallite size La of nanographite by Raman spectroscopy. Appl. Phys. Lett. 88, 163106 2006

P.B. Barna M. Adamik: Fundamental structure forming phenomena of polycrystalline films and the structure zone models. Thin Solid Films 317, 27 1998

S. Chowdhury, M.T. Laugier I.Z. Rahman: Characterization of DLC coatings deposited by rf magnetron sputtering. J. Mater. Proc. Technol. 153–154, 804 2004

Acknowledgments

The authors appreciate the use of the facilities in Advanced Coatings Applied Research Laboratory (ACARL), Hong Kong, China, which was supported by the Innovation Technology Fund of Hong Kong. The work described in this article was supported by the Research Grant of the City University of Hong Kong under Project No. 7001942.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, Y.H., Shen, Y.G. Nanostructure evolution and properties of two-phase nc-Ti(C, N)/a-(C, CNx) nanocomposites by high-resolution transmission electron microscopy, x-ray photoelectron spectroscopy, and Raman spectroscopy. Journal of Materials Research 22, 2460–2469 (2007). https://doi.org/10.1557/jmr.2007.0304

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2007.0304