Abstract

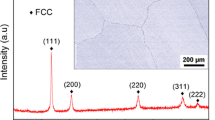

The strain-rate sensitivity of ultrafine-grained aluminum (Al) and nanocrystalline nickel (Ni) is studied with an improved nanoindentation creep method. Using the dynamic contact stiffness thermal drift influences can be minimized and reliable creep data can be obtained from nanoindentation creep experiments even at enhanced temperatures and up to 10 h. For face-centered cubic (fcc) metals it was found that the creep behavior is strongly influenced by the microstructure, as nanocrystalline (nc) as well as ultrafine-grained (ufg) samples show lower stress exponents when compared with their coarse-grained (cg) counterparts. The indentation creep behavior resembles a power-law behavior with stress exponents n being ∼ 20 at room temperature. For higher temperatures the stress exponents of ufg-Al and nc-Ni decrease down to n ∼ 5. These locally determined stress exponents are similar to the macroscopic exponents, indicating that similar deformation mechanisms are acting during indentation and macroscopic deformation. Grain boundary sliding found around the residual indentations is related to the motion of unconstrained surface grains.

Similar content being viewed by others

References

H.W. Höppel, J. May, P. Eisenlohr, and M. Göken: Strain-rate sensitivity of ultrafine-grained materials. Z. Metallkd. 96, 6 (2005).

J. May, H.W. Höppel, and M. Göken: Strain rate sensitivity of ultrafine-grained aluminium processed by severe plastic deformation. Scr. Mater. 53, 189 (2005).

N.Q. Chinh, P. Szommer, Z. Horita, and T.G. Langdon: Experimental evidence for grain-boundary sliding in ultrafine-grained aluminum processed by severe plastic deformation. Adv. Mater. 18, 34 (2006).

Y.J. Li, J. Mueller, H.W. Höppel, M. Göken, and W. Blum: Deformation kinetics of nanocrystalline nickel. Acta Mater. 55, 5708 (2007).

Q. Wei, S. Cheng, K.T. Ramesh, and E. Ma: Effect of nanocrystalline and ultrafine grain sizes on the strain rate sensitivity and activation volume: fcc versus bcc metals. Mater. Sci. Eng., A 381, 71 (2004).

H.W. Höppel, J. May, and M. Göken: Enhanced strength and ductility in ultrafine-grained aluminium produced by accumulative roll bonding. Adv. Eng. Mater. 6, 781 (2004).

M.J. Mayo and W.D. Nix: A micro-indentation study of superplasticity in Pb, Sn, and Sn-38 wt% Pb. Acta Mater. 36, 2183 (1988).

R. Schwaiger, B. Moser, M. Dao, N. Chollacoop, and S. Suresh: Some critical experiments on the strain-rate sensitivity of nanocrystalline nickel. Acta Mater. 51, 5159 (2003).

H. Vehoff, D. Lemaire, K. Schüler, T. Waschkies, and B. Yang: The effect of grain size on strain rate sensitivity and activation volume - from nano to ufg nickel. Int. J. Mater. Res. 98, 259 (2007).

J. Alkorta, J.M. Martinez-Esnaola, and J. Gil Sevillano: Critical examination of strain-rate sensitivity measurement by nanoindentation methods: Application to severely deformed niobium. Acta Mater. 56, 884 (2008).

V. Maier, K. Durst, J. Mueller, B. Backes, H.W. Höppel, and M. Göken: Nanoindentation strain-rate jump tests for determining the local strain-rate sensitivity in nanocrystalline Ni and ultrafine-grained Al. J. Mater. Res. 26, 1421 (2011).

A.F. Bower, N.A. Fleck, A. Needleman, and N. Ogbonna: Indentation of a power law creeping solid. Proc. R. Soc. London, Ser. A 441, 97 (1993).

W.H. Poisl, W.C. Oliver, and B.D. Fabes: The relationship between indentation and uniaxial creep in amorphous selenium. J. Mater. Res. 10, 2024 (1995).

B.N. Lucas and W.C. Oliver: Indentation power-law creep of high-purity indium. Metal. Mater. Trans. A 30, 601 (1999).

D.S. Stone, J.E. Jackes, J. Puthoff, and A.A. Elmustafa: Analysis of indentation creep. J. Mater. Res. 25, 611 (2010).

I-C. Choi, B-G. Yoo, Y-J. Kim, and J-I. Jang: Indentation creep revisited. J. Mater. Res. 27, 3 (2012).

R. Goodall and T.W. Clyne: A critical appraisal of the extraction of creep parameters from nanoindentation data obtained at room temperature. Acta Mater. 54, 5489 (2006).

T.P. Weihs and J.B. Pethica: Monitoring time-dependent deformation in small volumes, in Thin Films: Stresses and Mechanical Properties III, edited by W.D. Nix, J.C. Bravman, E. Arzt, and L.B. Freund (Mater. Res. Soc. Symp. Proc. 239, Pittsburgh, PA, 1992), p. 325.

J.B. Pethica and W.C. Oliver: Tip surface interactions in STM and AFM. Phys. Scr. T. 19, 61 (1987).

S.A. Syed Asif and J.B. Pethica: Nanoindentation of single-crystal tungsten and gallium arsenide. Philos. Mag. A 76, 1105 (1997).

D.L. Goldsby, A. Rar, G.M. Pharr, and T.E. Tullis: Nanoindentation creep of quartz, with implication for rate- and state-variable friction laws relevant to earthquake mechanics. J. Mater. Res. 19, 357 (2004).

B.D. Beake and J.F. Smith: High-temperature nanoindentation testing of fused silica and other materials. Philos. Mag. A 82, 2179 (2002).

S. Korte and W.J. Clegg: Micropillar compression of ceramics at elevated temperatures Scr. Mater. 60, 807 (2009).

J.M. Wheeler, R. Raghavan, and J. Michler: In-situ SEM indentation of Zr-based bulk maetallic glas at elevated temperatures. Mater. Sci. Eng., A 528, 8750 (2011).

C.A. Schuh, A.L. Lund, and T.G. Nieh: New regime of homogenous flow in the deformation map of metallic glasses: Elevated temperature nanoindentation experiments and mechanistic modeling. Acta Mater. 52, 5879 (2004).

Z.C. Duan and A.M. Hodge: High-temperature nanoindentation: New developments and ongoing challenges. JOM 61, 32 (2009).

B.N. Lucas and W.C. Oliver: Time dependent indentation testing at non-ambient temperatures utilizing the high temperature mechanical properties microprobe, in Thin Films: Stresses and Mechanical Properties V, edited by S.P. Baker, C.A. Ross, P.H. Townsend, C.A. Volkert, and P. Børgesen (Mater. Res. Soc. Symp. Proc. 356, Pittsburgh, PA, 1995), p. 645.

S.A. Syed Asif and J.B. Pethica: Nano-scale indentation creep testing at non-ambient temperature. J. Adhes. 67, 153 (1997).

A. Sawant and S. Tin: High temperature nanoindentation of Re-bearing single crystal Ni-base superalloy. Scr. Mater. 52, 275 (2008).

C.L. Wang, M. Zhang, and T.G. Nieh: Nanoindentation creep of nanocrystalline Nickel at elevated temperatures. J. Phys. D: Appl. Phys. 42, 115405 (2009).

H. Natter and R. Hempelmann: Tailor-made nanomaterials designed by electrochemical methods. Electrochim. Acta 49, 51 (2003).

W.C. Oliver and G.M. Pharr: Improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

I.N. Sneddon: The relation between load and penetration in the axisymmetric boussinesq problem for a punch of arbitrary profile. Int. J. Eng. Sci. 3, 47 (1965).

B. Merle, V. Maier, M. Göken, and K. Durst: Experimental determination of the effective indenter shape and ε-factor for nanoindentation by continuously measuring the unloading stiffness. J. Mater. Res. 27, 214 (2012).

T.O. Mulhearn and D. Tabor: Creep and hardness of metals: A physical study. J. Inst. Met. 89, 7 (1960).

Y-T. Cheng and C-M. Cheng: Scaling relationships in indentation of power-law creep solids using self-similar indenters. Philos. Mag. Lett. 81, 9 (2001).

D.L. Joslin and W.C. Oliver: A new method for analyzing data from continous depth-sensing microindentation tests. J. Mater. Res. 5, 123 (1990).

J.L. Hay, W.C. Oliver, A. Bolshakov, and G.M. Pharr: Using the ratio of loading slope and elastic stiffness to predict pile-up and constraint factor during indentation, in Fundamentals of Nanoindentation and Nanotribology, edited by N.R. Moody, W.W. Gerberich, N. Burnham, and S.P. Baker (Mater. Res. Soc. Symp. Proc. 522, Warrendale, PA, 1998), p. 101.

A.G. Atkins and D. Tabor: Plastic indentation in metals with cones. J. Mech. Phys. Sol. 13, 149 (1965).

C. Su, J.A. LaManna, Y. Gao, W.C. Oliver, and G.M. Pharr: Plastic instability in amorphous selenium near its glass transition temperature. J. Mater. Res. 25, 1015 (2010).

W.B. Li, J.L. Henshall, R.M. Hooper, and K.E. Easterling: The mechanics of indentation creep. Acta Metal. Mater. 39, 3099 (1991).

G. Simmons and H. Wang: Single Crystal Elastic Constants and Calculated Aggregate Properties–A Handbook (MIT Press, Cambridge, MA, 1971).

E.O. Hall: The deformation and ageing of mild steel: III discussion of results. Proc. Phys. Soc. B 64, 747 (1951).

N.J. Petch: The cleavage strength of polycrystals. J. Iron Steel Inst. 174, 25 (1953).

V. Sklenicka, J. Dvorak, and M. Svoboda: Creep in ultrafine grained aluminium. Mater. Sci. Eng., A 387–389, 696 (2004).

W. Blum and Y.J. Li: Creep of ultrafine-grained Al and Cu produced by severe plastic deformation. Mater. Sci. Tech. 1, 65 (2005).

W. Blum and Y.J. Li: Flow stress and creep rate of nanocrystalline Ni. Scr. Mater. 57, 429 (2007).

M.A. Meyers, A. Misha, and D.J. Benson: Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 51, 427 (2006).

M.E. Kassner and M-T. Pérez-Prado: Five-power-law creep in single phase metals and alloys. Prog. Mater. Sci. 45, 1 (2000).

K. Zhang, J.R. Weertman, and J.A. Eastman: The influence of time, temperature, and grain size on indentation creep in high-purity nanocrystalline ultrafine-grain copper. Appl. Phys. Lett. 85, 5197 (2004).

M. Jin, A.M. Minor, E.A. Stach, and J.W. Morris Jr.: Direct observation of deformation-induced grain-growth during the nanoindentation of ultrafine-grained Al at room-temperature. Acta Mater. 52, 5381 (2004).

D.S. Gianola, S. Van Petergem, M. Legros, S. Brandstetter, H. Van Swygenhoven, and K.J. Hemker: Stress-assisted discontinuous grain growth and its effect on the deformation behavior of nanocrytsalline aluminum thin films. Acta Mater. 54, 2253 (2006).

D. Pan, T.G. Nieh, and M.W. Chen: Strengthening and softening of nanocrystalline nickel during multistep nanoindentation. Appl. Phys. Lett. 88, 161922 (2006).

A. Bolshakov and G.M. Pharr: Influences of pileup on the measurement of mechanical properties by load and depth sensing indentation techniques. J. Mater. Res. 13, 1049 (1998).

A. Böhner, V. Maier, K. Durst, H.W. Höppel, and M. Göken: Macro- and nanomechanical properties and strain rate sensitivity of accumulative roll bonded and equal channel angular pressed ultrafine-grained materials. Adv. Eng. Mater. 13, 251 (2011).

Y.M. Wang, A.V. Hamza, and E. Ma: Temperature-dependent strain rate sensitivity and activation volume of nanocrystalline Ni. Acta Mater. 54, 2715 (2006).

ACKNOWLEDGMENTS

The authors gratefully acknowledge the kind support of Dr. Holger Pfaff, Agilent Technologies, and the very helpful discussions with Dr. H.W. Höppel. Financial support was provided by the German Research Council (DFG), which, within the framework of its “Excellence Initiative” supports the Cluster of Excellence “Engineering of Advanced Materials” at the University of Erlangen-Nürnberg and by the Bayerische Forschungsstiftung (BFS) within the project “Galvano 21”.

Author information

Authors and Affiliations

Corresponding author

Appendix: Experimental details for the nanoindentation long-term creep testing

Appendix: Experimental details for the nanoindentation long-term creep testing

Figure A1 shows the results of long-term creep tests at RT on ufg-Al with an initial indentation depth of 1000 nm and various creep durations up to 10 h. Included in the plot is also the temperature variation within the indenter chamber. The temperature fluctuates between 23.2 and 23.6 °C within a 10 h test segment. The displacements recorded by the nanoindenter are nonreproducible and unsteady as it directly reflects the slight changes in the chamber temperature. The temperature fluctuation causes therefore thermal drift effects, which can be easily corrected by using the dynamic stiffness signal [Fig. A1(a) ]. The corrected data based on the contact stiffness measurements show for all measurements a small but steady increase in the displacement with time and a better reproducibility [Fig. A1(b)].

ufg-Al—Creep data carried out during nanoindentation long-term creep tests at 1000 nm indentation depth and tested at room temperature (RT) with variation of the applied creep time (1 h, 2 h, 5 h, and 10 h); (a) Indentation depth data from the indentation system and exemplarily corresponding ambient temperature during 10 h experiment, (b) corrected indentation depth data according to Eqs. (2) and (4), (c) resultant \(\dot h\). over creep time (with fused silica as a reference material), and (d) hardness over resulting creep-rate.

A good agreement between the different measurements of \(\dot h\) over the applied creep time performed for ufg-Al is shown in Fig. A1(c). This demonstrates the consistency of the long-term nanoindentation data and it also confirms that the evaluation based on the contact stiffness is more or less not affected by thermal drift. More generally, the changes in the indentation depth \(\dot h\) as well as the resultant creep-rates \({{\dot \varepsilon }}\) clearly decrease with increasing creep time, but never run in a plateau. Accordingly, indentation creep tests were also carried out for 2 h on fused silica. In comparison with ufg-Al, fused silica shows a significantly lower change in indentation depth [Fig. A1(c) ] and thus a lower creep rate [Fig. A1(d) ]. Generally, the increasing indentation depth is mainly caused by plastic deformation processes due to the applied constant load during the creep experiment. However, a pile-up formation or grain coarsening during creep might also lead to an increasing contact area and thus to an increasing creep rate or to a reduced hardness.

The resultant impressions from the long-term nanoindentation were intensively studied using SEM and FIB (Fig. A2). Magnifying the grains along the indenter edges show no significant grain coarsening during the long-term indentation experiments. By evaluating the projected contact areas (Ac−SEM) from these SEM images, a good agreement between the contact areas, determined from the dynamic CSM method and Ac−SEM was found. Therefore, additional pile-up effects or grain coarsening can be neglected here for the evaluation of the nanoindentation creep data.

SEM images of different indentations in ufg-Al varying the applied creep time (according to Fig. A1).

Rights and permissions

About this article

Cite this article

Maier, V., Merle, B., Göken, M. et al. An improved long-term nanoindentation creep testing approach for studying the local deformation processes in nanocrystalline metals at room and elevated temperatures. Journal of Materials Research 28, 1177–1188 (2013). https://doi.org/10.1557/jmr.2013.39

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2013.39