Abstract

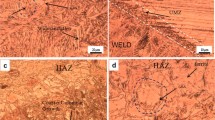

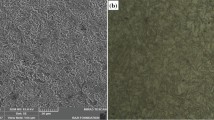

The joint of dissimilar metals between Mo2FeB2-based cermets and 316L stainless steel was welded by gas tungsten arc welding with no fillers. The weldability was investigated by plate rigid restraint cracking test and transverse rupture strength was measured by the three-point bending test. Microstructure of the weld joint was studied with scanning electron microscope, energy-dispersive spectrometer, X-ray diffractometer and differential scanning calorimeter, etc. Corrosion behavior was investigated by the potentiodynamic polarization test. Results revealed that weld solidification cracking susceptibility existed in the fusion zone. Coarse irregular complex ternary boride phase (M3B2) and hypoeutectic microstructure were formed in weld metal (WM). In heat affected zone (HAZ), a small number of M3B2 grains dissolved into the γ-Fe based binder, with growth and coalescence of the remaining M3B2 grains. Microhardness of HAZ increased slightly and WM presented the highest microhardness in the whole joint. Besides, potentiodynamic polarization test showed that WM had a better corrosion resistance than Mo2FeB2-based cermets, which can be attributed to the higher Cr content and relatively homogenous Mo distribution.

Similar content being viewed by others

References

K. Takagi: Development and application of high strength ternary boride base cermets. J. Solid State Chem. 179(9), 2809 (2006).

K. Takagi, W. Koike, A. Momozawa, and T. Fujima: Effects of Cr on the properties of Mo2NiB2 ternary boride. Solid State Sci. 14(11), 1643 (2012).

K. Takagi: High tough boride base cermets produced by reaction sintering. Mater. Chem. Phys. 67(1), 214 (2001).

K. Takagi, M. Komai, T. Ide, T. Watanabe, and Y. Kondo: Effects of Mo and Cr contents on the properties and phase formation of iron molybdenum boride base hard alloys. Powder Metall. Int. 19(5), 30 (1987).

K. Takagi, M. Komai, T. Ide, T. Watanabe, and Y. Kondo: Effect of Ni on the mechanical properties of Fe, Mo boride hard alloys. Int. J. Powder Metall. 23(3), 157 (1987).

X. Pang, Y. Zheng, S. Wang, and Q. Wang: Effect of Mn on valence-electron structure and properties of hard phase in Mo2FeB2-based cermets. Int. J. Refract. Hard Met. 27(4), 777 (2009).

H. Yu, Y. Zheng, W. Liu, J. Zheng, and W. Xiong: Effect of V content on the microstructure and mechanical properties of Mo2FeB2 based cermets. Mater. Des. 31(5), 2680 (2010).

Y. Wang and Z. Li: Development of ternary-boride-based hard cladding material. Mater. Res. Bull. 37(3), 417 (2002).

M.A. Zhuang, W. Wei, J. Zou, S. Dong, L. Zhang, and Z. Li: Preparation and properties of flame-sprayed Mo-FeB-Fe cermet coatings. Trans. Nonferrous Met. Soc. China 21(6), 1314 (2011).

J.S. Peng, Y.J. Pan, and H. Zhang: The influence of heat treatment on the interface and properties of Mo2FeB2 cermets-steel clad material. Appl. Mech. Mater. 541, 199 (2014). Trans Tech Publications Inc.

F.K. Yan, G.Z. Liu, N.R. Tao, and K. Lu: Strength and ductility of 316L austenitic stainless steel strengthened by nano-scale twin bundles. Acta Mater. 60(3), 1059 (2012).

M.D. Mathew, K. Laha, and V. Ganesan: Improving creep strength of 316L stainless steel by alloying with nitrogen. Mater. Sci Eng., A 535, 76 (2012).

X.H. Chen, J. Lu, L. Lu, and K. Lu: Tensile properties of a nanocrystalline 316L austenitic stainless steel. Scr. Mater. 52(10), 1039 (2005).

R. Kaçar and O. Baylan: An investigation of microstructure/property relationships in dissimilar welds between martensitic and austenitic stainless steels. Mater. Des. 25(4), 317 (2004).

J.C. Lippold: Welding Metallurgy and Weldability (Hoboken, NJ, John Wiley & Sons, 2014).

I. Medovar: On the nature of weld hot cracking. Avtomatich. Svarka 7, 12 (1954).

S.M. Chung, A. Yap, S.P. Chandra, and C.T. Lim: Flexural strength of dental composite restoratives: Comparison of biaxial and three-point bending test. J. Biomed. Mater. Res., Part B 71(2), 278 (2004).

H. Yu, Y. Zheng, W. Liu, X. Pang, J. Zheng, and W. Xiong: Effect of Mo/B atomic ratio on the microstructure and mechanical properties of Mo2FeB2 based cermets. Int. J. Refract. Hard Met. 28(3), 338 (2010).

S. Ming, H. Yu, W. Liu, and Y. Zheng: Investigation of phase transformation and microstructure evolution of Mo2FeB2-based cermet I: Phase transformation. Cem. Carbide 3, 2 (2011). [In Chinese].

Y. Zheng, H. Yu, and W. Liu: Investigation of phase transformation and microstructure evolution of Mo2FeB2-based cermet II: Microstructure evolution. Cem. Carbide 4, 2 (2011). [In Chinese].

T. Ide and T. Ando: Reaction sintering of an Fe-6 wt pct B-48 wt pct Mo alloy in the presence of liquid phases. Metall. Mater. Trans. A. 20(1), 17 (1989).

H. Yu, W. Liu, and Y. Zheng: Microstructure and mechanical properties of liquid phase sintered Mo2FeB2 based cermets. Mater. Des. 32(6), 3521 (2011).

D. Askeland and W. Wright: Essentials of Materials Science & Engineering (Stamford, CT, Cengage Learning, 2013).

T. Balusamy, S. Kumar, and T.S.N. Sankara Narayanan: Effect of surface nanocrystallization on the corrosion behaviour of AISI 409 stainless steel. Corros. Sci. 52(11), 3826 (2010).

Y. Hao, B. Deng, C. Zhong, Y. Jiang, and J. Li: Effect of surface mechanical attrition treatment on corrosion behavior of 316 stainless steel. J. Iron Steel Res. Int. 16(2), 68 (2009).

M. Laleh and F. Kargar: Suppression of chromium depletion and sensitization in austenitic stainless steel by surface mechanical attrition treatment. Mater. Lett. 65(12), 1935 (2011).

T. Balusamy, T. Sankara Narayanan, K. Ravichandran, I.S. Park, and M.H. Lee: Influence of surface mechanical attrition treatment (SMAT) on the corrosion behaviour of AISI 304 stainless steel. Corros. Sci. 74, 332 (2013).

D.J. Kotecki and J.C. Lippold: Welding Metallurgy and Weldability of Stainless Steels (John Wiley, Hoboken, New Jersey, 2005).

J. Lee: Effects of alloying elements, Cr, Mo and N on repassivation characteristics of stainless steels using the abrading electrode technique. Mater. Chem. Phys. 99(2), 224 (2006).

E.I. Gladyshevskii, T.F. Fedorov, Y.B. Kuz’Ma, and R.V. Skolozdra: Isothermal section of the molbdenum-iron-boron system. Powder Metall. Met. Ceram. 5(4), 305 (1966).

ACKNOWLEDGMENTS

The authors gratefully acknowledge the support provided by the Natural Science Foundation of Shandong Province (ZR2010EM067) and Innovation Fund for Technology Based Firms (11C26213702324).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Geng, S., Sun, J., Guo, L. et al. Characterization of weldability, microstructure, and corrosion resistance of dissimilar welded joint between Mo2FeB2-based cermets and 316L stainless steel. Journal of Materials Research 30, 3653–3662 (2015). https://doi.org/10.1557/jmr.2015.311

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.311