Abstract

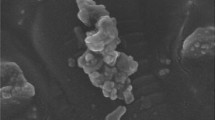

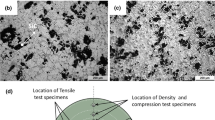

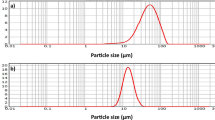

Boron carbide (B4C) ceramic particles were used as reinforcement material to produce aluminum (Al) matrix composites by squeeze casting method. Four different B4C contents as 0, 3, 5, and 10 wt%, and three different squeeze pressures as 0, 75, and 150 MPa were used in which the samples consisted of pure Al without B4C and the samples obtained without applying pressure were used as control samples. To determine the effect of squeezing pressure and the amount of B4C added on machinability and mechanical properties, average chip length and surface roughness of the samples were evaluated and hardness measurements were accomplished, yield and ultimate tensile strengths were determined, respectively. Also, the changes in density and microstructure were investigated. B4C reinforcement was found to decrease the average chip length and density of the samples while increasing the hardness and surface roughness. On the other hand, application of squeeze pressure had a positive effect on the densification and mechanical properties of the samples.

Similar content being viewed by others

References

N. Chawla and K.K. Chawla: Metal Matrix Composites (Springer, New York, 2006).

D.K. Koli, G. Agnihotri, and R. Purohit: Advanced aluminium matrix composites: The critical need of automotive and aerospace engineering fields. Mater. Today: Proc. 2 (4–5), 3032 (2015).

A. Macke, B.F. Schultz, and P. Rohatgi: Metal matrix composites offer the automotive industry an opportunity to reduce vehicle weight, improve performance. Adv. Mater. Processes 170 (3), 19 (2012).

W.Q. Song, P. Krauklis, A.P. Mauritz, and S. Bandyopadhyay: The effect of thermal ageing on the abrasive behavior of age-hardening Al/SiC and 6061 Al/SiC composites. Wear 185 (1–2), 125 (1995).

R. Harichandran and N. Selvakumar: Effect of nano/micro B4C particles on the mechanical properties of aluminium metal matrix composites fabricated by ultrasonic cavitation-assisted solidification process. Arch. Civ. Mech. Eng. 16 (1), 147 (2016).

Y. Wang, K. Lei, Y. Ruan, and W. Dong: Microstructure and wear resistance of c-BN/Ni–Cr–Ti composites prepared by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 54, 98 (2016).

S.B. Kim, D.A. Koss, and D.A. Gerard: High cycle fatigue of squeeze cast Al/SiCw composites. Mater. Sci. Eng., A 277 (1–2), 123 (2000).

L. Saravanan and T. Senthilvelan: Investigations on the hot workability characteristics and deformation mechanisms of aluminium alloy-Al2O3 nanocomposite. Mater. Des. 79, 6 (2015).

S. Takahashi, Y. Imai, A. Kan, Y. Hotta, and H. Ogawa: Improvements in the temperature-dependent properties of dielectric composites by utilizing MgO whiskers as the dielectric filler in an iPP matrix. J. Alloys Compd. 640, 428 (2015).

P. Sharma, S. Sharma, and D. Khanduja: Production and some properties of Si3N4 reinforced aluminium alloy composites. J. Asian Ceram. Soc. 3 (3), 352 (2015).

S. Johny James, K. Venkatesan, P. Kuppan, and R. Ramanujam: Hybrid aluminium metal matrix composite reinforced with SiC and TiB2. Procedia Eng. 97, 1018 (2014).

K. Chen, Y. Hua, C. Xu, Q. Zhang, C. Qi, and Y. Jie: Preparation of TiC/SiC composites from Ti-enriched slag by an electrochemical process in molten salts. Ceram. Int. 41 (9) Part A, 11428 (2015).

A. Baradeswaran, S.C. Vettivel, A.E. Perumal, N. Selvakumar, and R.F. Issac: Experimental investigation on mechanical behaviour, modelling and optimization of wear parameters of B4C and graphite reinforced aluminium hybrid composites. Mater. Des. 63, 620 (2014).

P.K. Jayashree, M.C. Gowri Shankar, K. Achutha, S.S. Sharma, and S. Raviraj: Review on effect of silicon carbide (SiC) on stir cast aluminium metal matrix composites. Inter. J. Curr. Eng. Technol. 3 (3), 1061 (2013).

V. Auradi, G.L. Rajesh, and S.A. Kori: Processing of B4C particulate reinforced 6061 aluminum matrix composites by melt stirring involving two-step addition. Procedia Mater. Sci. 6, 1068 (2014).

E.M. Sharifi, F. Karimzadeh, and M.H. Enayati: Fabrication and evaluation of mechanical and tribological properties of boron carbide reinforced aluminum matrix nanocomposites. Mater. Des. 32, 3263 (2011).

L. Poovazhagan, K. Kalaichelvan, and T. Sornakumar: Processing and performance characteristics of aluminum-nano boron carbide metal matrix nanocomposites. Mater. Manuf. Processes 31, 1275 (2016).

Y.T. Yao and L.Q. Chen: B4C/Al composites processed by metal-assisted pressureless infiltration technique and its characterization. Mater. Manuf. Processes 31, 1286 (2016).

K.M. Shorowordi, A.S.M.A. Haseeb, and J.P. Celis: Tribo-surface characteristics of Al–B4C and Al–SiC composites worn under different contact pressures. Wear 261, 634 (2006).

K.B. Lee, H.S. Sim, S.Y. Cho, and H. Kwon: Tensile properties of 5052 Al matrix composites reinforced with B4C. Metall. Mater. Trans. A 32, 2142 (2001).

B. Ravi, B. Balu Naik, and J. Udaya Prakash: Characterization of aluminium matrix composites (AA6061/B4C) fabricated by stir casting technique. Mater. Today: Proceed. 2 (4–5), 2984 (2015).

S.M. Skolianos, G. Kiourtsidis, and T. Xatzifotiou: Effects of applied pressure on the microstructure and mechanical properties of squeeze-cast AA6061 alloy. Mater. Sci. Eng., A 231 (1–2), 17 (1997).

I.G. Crouch: Aluminium Squeeze Casting Technology, A European Researchers Viewpoint (Australian Conference on Materials for Industrial Development, Christchurch, New Zealand, 1987); p. 24.

M. Masoumi and H. Hu: Influence of applied pressure on microstructure and tensile properties of squeeze cast magnesium Mg–Al–Ca Alloy. Mater. Sci. Eng., A 528 (10–11), 3589 (2011).

Y. Zhang, G. Wu, W. Liu, L. Zhang, S. Pang, Y. Wang, and W. Ding: Effects of processing parameters and Ca content on microstructure and mechanical properties of squeeze casting AZ91–Ca alloys. Mater. Sci. Eng., A 595, 109 (2014).

T.R. Vijayaram, S. Sulaiman, A.M.S. Hamouda, and M.H.M. Ahmad: Fabrication of fiber reinforced metal matrix composites by squeeze casting technology. J. Mater. Process. Technol. 178 (1–3), 34 (2006).

W. Chen, Y. Liu, C. Yang, D. Zhu, and Y. Li: (SiCp+Ti)/7075Al hybrid composites with high strength and large plasticity fabricated by squeeze casting. Mater. Sci. Eng., A 609, 250 (2014).

R.B. Bhagat: High pressure squeeze casting of stainless steel wire reinforced aluminium matrix composites. Composites 19 (5), 393 (1988).

Q. Hu, H. Zhao, and F. Li: Effects of manufacturing processes on microstructure and properties of Al/A356–B4C composites. Mater. Manuf. Processes 31, 1292 (2016).

F. Toptan, A. Kilicarslan, and I. Kerti: The effect of Ti addition on the properties of Al–B4C interface: A microstructural study. Mater. Sci. Forum 636–637, 192 (2010).

O. Baskaya: The mechanical properties and machinability of ZA-27 casting alloys. M.Sc. Thesis, Bogazici University, 2004.

ASTM E8/E8M-09 Standard Test Methods for Tension Testing of Metallic Materials: www.astm.org, 2013.

T. Ozben, E. Kilickap, and O. Cakır: Investigation of mechanical and machinability properties of SiC particle reinforced Al-MMC. J. Mater. Process. Technol. 198 (1–3), 220 (2008).

A. Baradeswaran and A. Elaya Perumal: Influence of B4C on the tribological and mechanical properties of Al 7075–B4C composites. Composites, Part B 54, 146 (2013).

M. Oluwatosin Bodunrin, K.K. Alaneme, and L.H. Chown: Aluminium matrix hybrid composites: A review of reinforcement philosophies; mechanical, corrosion and tribological characteristics. J. Mater. Res. Technol. 4 (4), 434 (2015).

K.T. Kashyap, C. Ramachandra, C. Dutta, and B. Chatterji: Role of work hardening characteristics of matrix alloys in the strengthening of metal matrix composites. Bull. Mater. Sci. 23 (1), 47 (2000).

W. Yang, R. Dong, Z. Yu, P. Wu, M. Hussain, and G. Wu: Strengthening behavior in high content SiC nanowires reinforced Al composite. Mater. Sci. Eng., A 648 (11), 41 (2015).

S. Emamy, E. Vaziri Yeganeh, A. Razaghian, and K. Tavighi: Microstructures and tensile properties of hot-extruded Al matrix composites containing different amounts of Mg2Si. Mater. Sci. Eng., A 586, 190 (2013).

H.R. Ezatpour, S.A. Sajjadi, M.H. Sabzevar, and Y. Huang: Investigation of microstructure and mechanical properties of Al6061-nanocomposite fabricated by stir casting. Mater. Des. 55, 921 (2014).

ACKNOWLEDGMENTS

The authors would like to thank to Mehdi Montakhab, Mustafa Sengor, and Fatih Oz for their assistance in the preparation of the squeeze casting setup.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ipekoglu, M., Nekouyan, A., Albayrak, O. et al. Mechanical characterization of B4C reinforced aluminum matrix composites produced by squeeze casting. Journal of Materials Research 32, 599–605 (2017). https://doi.org/10.1557/jmr.2016.495

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.495