Abstract

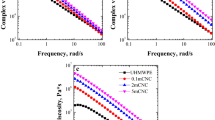

The rheological behavior of composites made with high-density polyethylene (HDPE) and chitosan was studied. Composites were prepared by melt processing in a laboratory internal mixer. Maleic anhydride grafted HDPE (PE-g-MA) was used as compatibilizer to enhance the dispersion of chitosan in the HDPE matrix. Different percentages of chitosan and compatibilizer (up to a maximum of 25 phr) were added into HDPE to prepare composites. Characterization of the composites with parallel plate rheometer and laboratory internal mixer revealed that the presence of chitosan increases the complex viscosity, loss modulus, storage modulus and the torque (i.e., melt viscosity), and the combination chitosan/compatibilizer has a similar, if slighter, effect. At higher filler levels it is clear that the PE-g-MA affected the microstructure of the compounds, possibly increasing matrix–filler interactions and acting as an effective compatibilizer.

Similar content being viewed by others

References

A. Peacock: Handbook of Polyethylene: Structures: Properties, and Applications (CRC Press, New York, 2000).

C. Vasile and M. Pascu: Practical Guide to Polyethylene (Rapra Technology Limited, Shawbury, 2005).

D.B. Malpass: Introduction to Industrial Polyethylene: Properties, Catalysts, and Processes (John Wiley & Sons, Hoboken, 2010).

S. Bonhomme, A. Cuer, A. Delort, J. Lemaire, M. Sancelme, and G. Scott: Environmental biodegradation of polyethylene. Polym. Degrad. Stab. 81 (3), 441 (2003).

G. Scott: Polymers and the Environment (Royal Society of Chemistry, Cambridge, 1999).

G. Swift and D. Wiles: Biodegradable and degradable polymers and plastics in landfill sites. In Encyclopedia of Polymer Science and Technology, J.I. Kroschwitz, ed. (John Wiley & Sons., Hoboken, 2004).

M. Sudhakar, M. Doble, P.S. Murthy, and R. Venkatesan: Marine microbe-mediated biodegradation of low-and high-density polyethylenes. Int. Biodeterior. Biodegrad. 61 (3), 203 (2008).

T. Ojeda, A. Freitas, K. Birck, E. Dalmolin, R. Jacques, F. Bento, and F. Camargo: Degradability of linear polyolefins under natural weathering. Polym. Degrad. Stab. 96 (4), 703 (2011).

R.A. Gross and B. Kalra: Biodegradable polymers for the environment. Science 297 (5582), 803 (2002).

Y.V. Kissin: Polyethylene: End-use Properties and Their Physical Meaning (Carl Hanser Verlag GmbH Co KG, Cincinnati, 2012).

M. Tolinski: Additives for Polyolefins: Getting the Most Out of Polypropylene, Polyethylene and TPO (William Andrew, Oxford, 2015).

S. Husseinsyah, A.N. Azmin, and H. Ismail: Effect of maleic anhydride-grafted-polyethylene (MAPE) and silane on properties of recycled polyethylene/chitosan biocomposites. Polym.-Plast. Technol. Eng. 52 (2), 168 (2013).

Y. Orhan, J. Hrenovic, and H. Buyukgungor: Biodegradation of plastic compost bags under controlled soil conditions. Acta Chim. Slov. 51 (3), 579 (2004).

S.Z. Rogovina, K.V. Aleksanyan, D.D. Novikov, E.V. Prut, and A.V. Rebrov: Synthesis and investigation of polyethylene blends with natural polysaccharides and their derivatives. Polym. Sci., Ser. A 51 (5), 554 (2009).

S.Z. Rogovina, C.V. Alexanyan, and E.V. Prut: Biodegradable blends based on chitin and chitosan: Production, structure, and properties. J. Appl. Polym. Sci. 121 (3), 1850 (2011).

H. Ismail, S.M. Shaari, and N. Othman: The effect of chitosan loading on the curing characteristics, mechanical and morphological properties of chitosan-filled natural rubber (NR), epoxidised natural rubber (ENR) and styrene-butadiene rubber (SBR) compounds. Polym. Test. 30 (7), 784 (2011).

V. Correlo, L. Boesel, M. Bhattacharya, J. Mano, N. Neves, and R. Reis: Properties of melt processed chitosan and aliphatic polyester blends. Mater. Sci. Eng., A 403 (1), 57 (2005).

O. Ermolovich and A. Makarevich: Effect of compatibilizer additives on the technological and performance characteristics of biodegradable materials based on starch-filled polyethylene. Russ. J. Appl. Chem. 79 (9), 1526 (2006).

D. Raghavan and A. Emekalam: Characterization of starch/polyethylene and starch/polyethylene/poly (lactic acid) composites. Polym. Degrad. Stab. 72 (3), 509 (2001).

C-S. Wu: A comparison of the structure, thermal properties, and biodegradability of polycaprolactone/chitosan and acrylic acid grafted polycaprolactone/chitosan. Polymer 46 (1), 147 (2005).

S. Husseinsyah, F. Amri, K. Husin, and H. Ismail: Mechanical and thermal properties of chitosan-filled polypropylene composites: The effect of acrylic acid. J. Vinyl Addit. Technol. 17 (2), 125 (2011).

H. Salmah, A. Faisal, and H. Kamarudin: Chemical modification of chitosan-filled polypropylene (PP) composites: The effect of 3-aminopropyltriethoxysilane on mechanical and thermal properties. Int. J. Polym. Mater. 60 (7), 429 (2011).

H. Salmah, F. Amri, and H. Kamarudin: Properties of chitosan-filled polypropylene (PP) composites: The effect of acetic acid. Polym.-Plast. Technol. Eng. 51 (1), 86 (2012).

F. Amri, S. Husseinsyah, and K. Hussin: Mechanical, morphological and thermal properties of chitosan filled polypropylene composites: The effect of binary modifying agents. Composites, Part A 46, 89 (2013).

O. Agboh and Y. Qin: Chitin and chitosan fibers. Polym. Adv. Technol. 8 (6), 355 (1997).

K. Chang, Y-S. Lin, and R. Chen: The effect of chitosan on the gel properties of tofu (soybean curd). J. Food Eng. 57 (4), 315 (2003).

P. Dutta, S. Tripathi, G. Mehrotra, and J. Dutta: Perspectives for chitosan based antimicrobial films in food applications. Food Chem. 114 (4), 1173 (2009).

B. Krajewska: Application of chitin-and chitosan-based materials for enzyme immobilizations: A review. Enzyme Microb. Technol. 35 (2), 126 (2004).

M.G. Peter: Applications and environmental aspects of chitin and chitosan. J. Macromol. Sci., Part A: Pure Appl. Chem. 32 (4), 629 (1995).

C. Pillai, W. Paul, and C.P. Sharma: Chitin and chitosan polymers: Chemistry, solubility and fiber formation. Prog. Polym. Sci. 34 (7), 641 (2009).

K.H. Prashanth and R. Tharanathan: Chitin/chitosan: Modifications and their unlimited application potential—An overview. Trends Food Sci. Technol. 18 (3), 117 (2007).

E.I. Rabea, M.E.-T. Badawy, C.V. Stevens, G. Smagghe, and W. Steurbaut: Chitosan as antimicrobial agent: Applications and mode of action. Biomacromolecules 4 (6), 1457 (2003).

S.A. Agnihotri, N.N. Mallikarjuna, and T.M. Aminabhavi: Recent advances on chitosan-based micro-and nanoparticles in drug delivery. J. Controlled Release 100 (1), 5 (2004).

J-K.F. Suh and H.W. Matthew: Application of chitosan-based polysaccharide biomaterials in cartilage tissue engineering: A review. Biomaterials 21 (24), 2589 (2000).

K.V. Reesha, S.K. Panda, J. Bindu, and T.O. Varghese: Development and characterization of an LDPE/chitosan composite antimicrobial film for chilled fish storage. Int. J. Biol. Macromol. 79, 934 (2015).

S. Khoramnejadian: Kinetic study of biodegradation of linear low density polyethylene/chitosan. Adv. Environ. Biol., 5 (10), 3050 (2011).

A. Martínez-Camacho, M. Cortez-Rocha, A. Graciano-Verdugo, F. Rodríguez-Félix, M. Castillo-Ortega, A. Burgos-Hernández, J. Ezquerra-Brauer, and M. Plascencia-Jatomea: Extruded films of blended chitosan, low density polyethylene and ethylene acrylic acid. Carbohydr. Polym. 91 (2), 666 (2013).

S. Mir, T. Yasin, P.J. Halley, H.M. Siddiqi, and T. Nicholson: Thermal, rheological, mechanical and morphological behavior of HDPE/chitosan blend. Carbohydr. Polym. 83 (2), 414 (2011).

A.O. Ogah, J.N. Afiukwa, and A.A. Nduji: Characterization and comparison of rheological properties of agro fiber filled high-density polyethylene bio-composites. Open J. Polym. Chem. 04 (01), 12 (2014).

S.I. Park, K.S. Marsh, and P. Dawson: Application of chitosan-incorporated LDPE film to sliced fresh red meats for shelf life extension. Meat Sci. 85 (3), 493 (2010).

J. Quiroz-Castillo, D. Rodríguez-Félix, H. Grijalva-Monteverde, T. del Castillo-Castro, M. Plascencia-Jatomea, F. Rodríguez-Félix, and P. Herrera-Franco: Preparation of extruded polyethylene/chitosan blends compatibilized with polyethylene-graft-maleic anhydride. Carbohydr. Polym. 101, 1094 (2014).

D.E. Rodríguez-Félix, J.M. Quiroz-Castillo, H. Grijalva-Monteverde, T. Castillo-Castro, S.E. Burruel-Ibarra, F. Rodríguez-Félix, T. Madera-Santana, R.E. Cabanillas, and P.J. Herrera-Franco: Degradability of extruded polyethylene/chitosan blends compatibilized with polyethylene-graft-maleic anhydride under natural weathering. J. Appl. Polym. Sci. 131 (22), 41045 (2014).

H. Salmah and A.N. Azieyanti: Properties of recycled polyethylene/chitosan composites: The effect of polyethylene-graft-maleic anhydride. J. Reinf. Plast. Compos. 30 (3), 195 (2010).

M. Sunilkumar, T. Francis, E.T. Thachil, and A. Sujith: Low density polyethylene–chitosan composites: A study based on biodegradation. Chem. Eng. J. 204–206, 114 (2012).

M. Sunilkumar, A.A. Gafoor, A. Anas, A.P. Haseena, and A. Sujith: Dielectric properties: A gateway to antibacterial assay—A case study of low-density polyethylene/chitosan composite films. Polym. J. 46 (7), 422 (2014).

C. Vasile, R. Darie, A. Sdrobiş, E. Paslaru, G. Pricope, A. Baklavaridis, S. Munteanu, and I. Zuburtikudis: Effectiveness of chitosan as antimicrobial agent in LDPE/CS composite films as minced poultry meat packaging materials. Cellul. Chem. Technol. 48 (3–4), 325 (2014).

C. Vasile, R.N. Darie, C.N. Cheaburu-Yilmaz, G-M. Pricope, M. Bračič, D. Pamfil, G.E. Hitruc, and D. Duraccio: Low density polyethylene–chitosan composites. Composites, Part B 55, 314 (2013).

H-s. Wang, D. Chen, and C-z. Chuai: Mechanical and barrier properties of LLDPE/chitosan blown films for packaging. Packag. Technol. Sci. 28 (10), 915 (2015).

H.Z. Zhang, Z.C. He, G.H. Liu, and Y.Z. Qiao: Properties of different chitosan/low-density polyethylene antibacterial plastics. J. Appl. Polym. Sci. 113 (3), 2018 (2009).

P.S. Lima, C.F. Guedes, D.L.A.C.S. Andrade, E.L. Canedo, and S.M.L. Silva: High density polyethylene/chitosan compounds: Effect of load level on thermal and mechanical properties. In 2nd Brazilian Conference on Composite Materials—BCCM2 (São José dos Campos, 2014).

Braskem: High Density Polyethylene JV-060U Technical Data Sheet, Revision 8 (São Paulo, 2015).

D. Walsh and P. Zoller: Standard Pressure Volume Temperature Data for Polymers (CRC Press, Lancaster, 1995).

T. Yui, K. Imada, K. Okuyama, Y. Obata, K. Suzuki, and K. Ogawa: Molecular and crystal structure of the anhydrous form of chitosan. Macromolecules 27 (26), 7601 (1994).

J. Li, J. Revol, E. Naranjo, and R. Marchessault: Effect of electrostatic interaction on phase separation behaviour of chitin crystallite suspensions. Int. J. Biol. Macromol. 18 (3), 177 (1996).

C.P.F. Santos and S.L.A. Dantas: Avaliação de uma amostra de quitosana comercial para uso no tratamento de efluentes têxteis. Presented at the 48th Brazilian Chemistry Meeting (Rio de Janeiro, 2008).

Addivant: Polybond 3009 Technical Information [www.addivant.com] (Danbury, 2013).

H. Moussout, H. Ahlafi, M. Aazza, and M. Bourakhouadar: Kinetics and mechanism of the thermal degradation of biopolymers chitin and chitosan using thermogravimetric analysis. Polym. Degrad. Stab. 130, 1 (2016).

W. Cox and E. Merz: Correlation of dynamic and steady-flow viscosities. J. Polym. Sci., Part A-2: Polym. Phys. 28, 619 (1958).

J.M. Dealy and R.G. Larson: Structure and Rheology of Molten Polymers (Hanser Publishers, Munich, 2006).

H.H. Winter: Three views of viscoelasticity for Cox–Merz materials. Rheol. Acta 48 (3), 241 (2009).

W. Gleissle and B. Hochstein: Validity of the Cox–Merz rule for concentrated suspensions. J. Rheol. 47 (4), 897 (2003).

M.M. Cross: Rheology of non-Newtonian fluids: A new flow equation for pseudoplastic systems. J. Colloid Sci. 20 (5), 417 (1965).

P.J. Carreau, D. De Kee, and R.P. Chhabra: Rheology of Polymeric Systems: Principles and Applications (Hanser Publishers, Munich, 1997).

R.B. Bird, R.C. Armstrong, and O. Hassager: Dynamics of polymeric liquids. In Fluid Mechanics, Vol. 1, 2nd ed. (John Wiley & Sons, New York, 1987).

H.M. Laun: Prediction of elastic strains of polymer melts in shear and elongation. J. Rheol. 30 (3), 459 (1986).

V. Sharma and G.H. McKinley: An intriguing empirical rule for computing the first normal stress difference from steady shear viscosity data for concentrated polymer solutions and melts. Rheol. Acta 51 (6), 487 (2012).

T.S. Alves, J.E.S. Neto, S.M.L. Silva, L.H. Carvalho, and E.L. Canedo: Process simulation of laboratory internal mixers. Polym. Test. 50, 94 (2016).

E.L. Canedo and L.N. Valsamis: Continuous Mixers, in Mixing and Compounding of Polymers, 2nd ed., I. Manas-Zloczower, ed. (Hanser Publishers, Munich, 2009); p. 1081.

M.D. Wetzel and C.K. Shih: Experimental simulation with a simple mixer and real material. In Mixing and Compounding of Polymers, I. Manas-Zloczower, ed. (Hanser Publishers, Munich, 2009); p. 479.

A.R.M. Costa, T.G. Almeida, S.M.L. Silva, L.H. Carvalho, and E.L. Canedo: Chain extension in poly (butylene-adipate-terephthalate). Inline testing in a laboratory internal mixer. Polym. Test. 42, 115 (2015).

A.A. Tavares, D.F. Silva, P.S. Lima, D.L. Andrade, S.M. Silva, and E.L. Canedo: Chain extension of virgin and recycled polyethylene terephthalate. Polym. Test. 50, 26 (2016).

I. Aranaz, M. Mengíbar, R. Harris, I. Paños, B. Miralles, N. Acosta, G. Galed, and Á. Heras: Functional characterization of chitin and chitosan. Curr. Chem. Biol. 3 (2), 203 (2009).

V. Hristov and J. Vlachopoulos: Effects of polymer molecular weight and filler particle size on flow behavior of wood polymer composites. Polym. Compos. 29 (8), 831 (2008).

H.A. Barnes, J.F. Hutton, and K. Walters: An Introduction to Rheology (Elsevier, Amsterdam, 1989).

A.V. Shenoy: Rheology of Filled Polymer Systems (Springer Science & Business Media, Dordrecht, 1999).

I.M. Krieger and T.J. Dougherty: A mechanism for non-Newtonian flow in suspensions of rigid spheres. Trans. Soc. Rheol. 3 (1), 137 (1959).

ACKNOWLEDGMENTS

The authors are grateful to the Braskem and Chemtura for the donation of the polyethylene resin and maleated polyethylene, and to the Conselho Nacional de Pesquisa (CNPq—Brazil), Grant # 478968/2013-2, Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES—Brazil) and Fundação de Amparo à Ciência e Tecnologia do Estado de Pernambuco (FACEPE—Brazil), DCR-0009-3.03/12, for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lima, P.S., Brito, R.S.F., Santos, B.F.F. et al. Rheological properties of HDPE/chitosan composites modified with PE-g-MA. Journal of Materials Research 32, 775–787 (2017). https://doi.org/10.1557/jmr.2016.519

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.519