Abstract

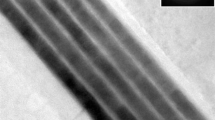

Thermal stability of pulsed laser deposited (PLD) nanocrystalline tantalum was explored through in situ transmission electron microscopy (TEM) annealing over the temperature range of 800–1200 °C. The evolution of the nanostructure was characterized using grain size distributions collectively with electron diffraction analysis and electron energy loss spectroscopy (EELS). Grain growth dynamics were further explored through molecular dynamics (MD) simulations of columnar tantalum nanostructures. The as-deposited grain size of 32 nm increased by only 18% at 1200 °C, i.e., 40% the melting point of tantalum, conflicting with the MD simulations that demonstrated extensive grain coalescence above 1000 °C. Furthermore, the grain size remained stable through the reversible α-to-β phase transition near 800 °C, which is often accompanied by grain growth in nanostructured tantalum. The EELS analysis confirmed the presence of oxygen impurities in the as-deposited films, indicating that impurity stabilization of grain boundaries was responsible for the exceptional thermal stability of PLD nanocrystalline tantalum.

Similar content being viewed by others

References

B.E. Schuster, J.P. Ligda, Z.L. Pan, and Q. Wei: Nanocrystalline refractory metals for extreme condition applications. JOM 63, 27 (2011).

E.M. Bringa, A. Caro, Y.M. Wang, M. Victoria, J.M. McNaney, B.A. Remington, R.F. Smith, B.R. Torralva, and H. Van Swygenhoven: Ultrahigh strength in nanocrystalline materials under shock loading. Science 309, 1838 (2005).

I.J. Beyerlein, A. Caro, M.J. Demkowicz, N.A. Mara, A. Misra, and B.P. Uberuaga: Radiation damage tolerant nanomaterials. Mater. Today 16, 443 (2013).

J.M. Dake and C.E. Krill, III: Sudden loss of thermal stability in Fe-based nanocrystalline alloys. Scr. Mater. 66, 390 (2012).

M. Ames, J. Markmann, R. Karos, A. Michels, A. Tschope, and R. Birringer: Unraveling the nature of room temperature grain growth in nanocrystalline materials. Acta Mater. 56, 4255 (2008).

G.D. Hibbard, J.L. McCrea, G. Palumbo, K.T. Aust, and U. Erb: An initial analysis of mechanisms leading to late stage abnormal grain growth in nanocrystalline Ni. Scr. Mater. 47, 83 (2002).

T. Chookajorn, H.A. Murdoch, and C.A. Schuh: Design of stable nanocrystalline alloys. Science 337, 951 (2012).

K.A. Darling, M.A. Tschopp, B.K. VanLeeuwen, M.A. Atwater, and Z.K. Liu: Mitigating grain growth in binary nanocrystalline alloys through solute selection based on thermodynamic stability maps. Comput. Mater. Sci. 84, 255 (2014).

J. Weissmuller: Alloy effects in nanostructures. Nanostruct. Mater. 3, 261 (1993).

R. Kirchheim: Grain coarsening inhibited by solute segregation. Acta Mater. 50, 413 (2002).

J.R. Trelewicz and C.A. Schuh: Grain boundary segregation and thermodynamically stable binary nanocrystalline alloys. Phys. Rev. B: Condens. Matter Mater. Phys. 79, 094112 (2009).

C.C. Koch, R.O. Scattergood, M. Saber, and H. Kotan: High temperature stabilization of nanocrystalline grain size: Thermodynamic versus kinetic strategies. J. Mater. Res. 28, 1785 (2013).

A. Michels, C.E. Krill, H. Ehrhardt, R. Birringer, and D.T. Wu: Modelling the influence of grain-size-dependent solute drag on the kinetics of grain growth in nanocrystalline materials. Acta Mater. 47, 2143 (1999).

B.G. Clark, K. Hattar, M.T. Marshall, T. Chookajorn, B.L. Boyce, and C.A. Schuh: Thermal stability comparison of nanocrystalline Fe-based binary alloy pairs. JOM 68, 1625 (2016).

S.N. Mathaudhu and K.T. Hartwig: Grain refinement and recrystallization of heavily worked tantalum. Mater. Sci. Eng., A 426, 128 (2006).

M. Bischof, S. Mayer, H. Leitner, H. Clemens, P. Staron, E. Geiger, A. Voiticek, and W. Knabl: On the development of grain growth resistant tantalum alloys. Int. J. Refract. Met. Hard Mater. 24, 437 (2006).

B.R. Levine, S. Sporer, R.A. Poggie, C.J. Della Valle, and J.J. Jacobs: Experimental and clinical performance of porous tantalum in orthopedic surgery. Biomaterials 27, 4671 (2006).

J.P. Strachan, A.C. Torrezan, G. Medeiros-Ribeiro, and R.S. Williams: Measuring the switching dynamics and energy efficiency of tantalum oxide memristors. Nanotechnology 22 (2011).

S.H. Yoo, T.S. Sudarshan, K. Sethuram, G. Subhash, and R.J. Dowding: Consolidation and high strain rate mechanical behavior of nanocrystalline tantalum powder. Nanostruct. Mater. 12, 23 (1999).

M. Zhang, B. Yang, J. Chu, and T.G. Nieh: Hardness enhancement in nanocrystalline tantalum thin films. Scr. Mater. 54, 1227 (2006).

Q. Wei, T. Jiao, S.N. Mathaudhu, E. Ma, K.T. Hartwig, and K.T. Ramesh: Microstructure and mechanical properties of tantalum after equal channel angular extrusion (ECAE). Mater. Sci. Eng., A 358, 266 (2003).

G. Guisbiers, E. Herth, L. Buchaillot, and T. Pardoen: Fracture toughness, hardness, and Young’s modulus of tantalum nanocrystalline films. Appl. Phys. Lett. 97 (2010).

Z.L. Pan, Y.L. Li, and Q. Wei: Tensile properties of nanocrystalline tantalum from molecular dynamics simulations. Acta Mater. 56, 3470 (2008).

J.P. Ligda, B.E. Schuster, and Q. Wei: Transition in the deformation mode of nanocrystalline tantalum processed by high-pressure torsion. Scr. Mater. 67, 253 (2012).

Y.M. Wang, A.M. Hodge, J. Biener, A.V. Hamza, D.E. Barnes, K. Liu, and T.G. Nieh: Deformation twinning during nanoindentation of nanocrystalline Ta. Appl. Phys. Lett. 86, 101915 (2005).

Q. Wei, Z.L. Pan, X.L. Wu, B.E. Schuster, L.J. Kecskes, and R.Z. Valiev: Microstructure and mechanical properties at different length scales and strain rates of nanocrystalline tantalum produced by high-pressure torsion. Acta Mater. 59, 2423 (2011).

A. Javed, H.G. Durrani, and C. Zhu: The effect of vacuum annealing on the microstructure, mechanical and electrical properties of tantalum films. Int. J. Refract. Met. Hard Mater. 54, 154 (2016).

M.H. Read and D.H. Hensler: X-ray analysis of sputtered films of beta-tantalum and body-centered cubic tantalum. Thin Solid Films 10, 123 (1972).

A.A. Navid and A.M. Hodge: Nanostructured alpha and beta tantalum formation—Relationship between plasma parameters and microstructure. Mater. Sci. Eng., A 536, 49 (2012).

L.A. Clevenger, A. Mutscheller, J.M.E. Harper, C. Cabral, Jr, and K. Barmak: The relationship between deposition conditions, the beta to alpha phase transformation, and stress relaxation in tantalum thin films. J. Appl. Phys. 72, 4918 (1992).

M. Zhang, Y.F. Zhang, P.D. Rack, M.K. Miller, and T.G. Nieh: Nanocrystalline tetragonal tantalum thin films. Scr. Mater. 57, 1032 (2007).

H.A. Murdoch and C.A. Schuh: Stability of binary nanocrystalline alloys against grain growth and phase separation. Acta Mater. 61, 2121 (2013).

R. Dannenberg, E.A. Stach, J.R. Groza, and B.J. Dresser: In situ TEM observations of abnormal grain growth, coarsening, and substrate de-wetting in nanocrystalline Ag thin films. Thin Solid Films 370, 54 (2000).

L.N. Brewer, D.M. Follstaedt, K. Hattar, J.A. Knapp, M.A. Rodriguez, and I.M. Robertson: Competitive abnormal grain growth between allotropic phases in nanocrystalline nickel. Adv. Mater. 22, 1161 (2010).

J.G. Brons and G.B. Thompson: A comparison of grain boundary evolution during grain growth in fcc metals. Acta Mater. 61, 3936 (2013).

J. Kacher, I.M. Robertson, M. Nowell, J. Knapp, and K. Hattar: Study of rapid grain boundary migration in a nanocrystalline Ni thin film. Mater. Sci. Eng., A 528, 1628 (2011).

P. Choi, M. da Silva, U. Klement, T. Al-Kassab, and R. Kirchheim: Thermal stability of electrodeposited nanocrystalline Co-1.1 at.% P. Acta Mater. 53, 4473 (2005).

O.K. Donaldson, K. Hattar, and J.R. Trelewicz: Metastable tantalum oxide formation during the devitrification of amorphous tantalum thin films. J. Am. Ceram. Soc. 99, 3775 (2016).

K. Hattar, D.M. Follstaedt, J.A. Knapp, and I.M. Robertson: Defect structures created during abnormal grain growth in pulsed-laser deposited nickel. Acta Mater. 56, 794 (2008).

A.J. Detor and C.A. Schuh: Microstructural evolution during the heat treatment of nanocrystalline alloys. J. Mater. Res. 22, 15 (2007).

J. Edington: Practical Electron Microscopy in Materials Science (van Nostrand Reinhold Company, New York, 1976).

S. Plimpton: Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1 (1995).

A.J. Haslam, S.R. Phillpot, H. Wolf, D. Moldovan, and H. Gleiter: Mechanisms of grain growth in nanocrystalline fcc metals by molecular-dynamics simulation. Mater. Sci. Eng., A 318, 293 (2001).

A.G. Froseth, H. Van Swygenhoven, and P.M. Derlet: Developing realistic grain boundary networks for use in molecular dynamics simulations. Acta Mater. 53, 4847 (2005).

R. Ravelo, T.C. Germann, O. Guerrero, Q. An, and B.L. Holian: Shock-induced plasticity in tantalum single crystals: Interatomic potentials and large-scale molecular-dynamics simulations. Phys. Rev. B: Condens. Matter 88, 134101 (2013).

A. Stukowski: Visualization and analysis of atomistic simulation data with OVITO-the open visualization tool. Modell. Simul. Mater. Sci. Eng. 18, 015012 (2010).

A. Stukowski: Structure identification methods for atomistic simulations of crystalline materials. Modell. Simul. Mater. Sci. Eng. 20, 045021 (2012).

D.H. Lowndes, D.B. Geohegan, A.A. Puretzky, D.P. Norton, and C.M. Rouleau: Synthesis of novel thin-film materials by pulsed laser deposition. Science 273, 898 (1996).

K.L. Chopra: Thin Film Phenomena, 1st ed. (McGraw-Hill Book Company, New York, 1969).

S. Schaltin, L. D’Urzo, Q. Zhao, A. Vantomme, H. Plank, G. Kothleitner, C. Gspan, K. Binnemans, and J. Fransaer: Direct electroplating of copper on tantalum from ionic liquids in high vacuum: Origin of the tantalum oxide layer. Phys. Chem. Chem. Phys. 14, 13624 (2012).

G.P. Williams: X-ray Data Booklet (Central for X-Ray Optics and Advanced Light Source, Lawrence Berkley National Laboratory, Berkeley, 2001).

F. Tang, D.S. Gianola, M.P. Moody, K.J. Hemker, and J.M. Cairney: Observations of grain boundary impurities in nanocrystalline Al and their influence on microstructural stability and mechanical behaviour. Acta Mater. 60, 1038 (2012).

C.J. Marvel, D. Yin, P.R. Cantwell, and M.P. Harmer: The influence of oxygen contamination on the thermal stability and hardness of nanocrystalline Ni–W alloys. Mater. Sci. Eng., A 664, 49 (2016).

A.J. Detor, M.K. Miller, and C.A. Schuh: Solute distribution in nanocrystalline Ni–W alloys examined through atom probe tomography. Philos. Mag. 86, 4459 (2006).

A.J. Detor and C.A. Schuh: Grain boundary segregation, chemical ordering and stability of nanocrystalline alloys: Atomistic computer simulations in the Ni–W system. Acta Mater. 55, 4221 (2007).

L.G. Feinstein and R.D. Huttemann: Factors controlling structure of sputtered Ta films. Thin Solid Films 16, 129 (1973).

ACKNOWLEDGMENTS

Support for this work was provided for OKD, WW, and JRT by the National Science Foundation through Grant DMR-1410941. The authors gratefully acknowledge Michael Marshall of the Radiation–Solid Interaction Group at Sandia National Laboratories for his assistance in the preparation of the PLD samples and Dr. Eric Stach of the Center for Functional Nanomaterials at Brookhaven National Laboratory for his help with the EELS measurements. The authors would also like to thank Dr. Stephen Foiles of Sandia National Laboratories for valuable feedback on the MD simulations. Analytical TEM and atomistic simulations were conducted at the Center for Functional Nanomaterials, Brookhaven National Laboratory, which is supported by the U.S. Department of Energy, Office of Basic Energy Sciences, under Contract No. DE-SC0012704. Sandia National Laboratories is a multiprogram laboratory managed and operated by Sandia Corporation, a wholly owned subsidiary of Lockheed Martin Corporation, for the US Department of Energy’s National Nuclear Security Administration under contract DE-AC04-94AL85000.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Donaldson, O.K., Wang, W., Hattar, K. et al. Impurity stabilization of nanocrystalline grains in pulsed laser deposited tantalum. Journal of Materials Research 32, 1351–1360 (2017). https://doi.org/10.1557/jmr.2017.68

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.68