Abstract

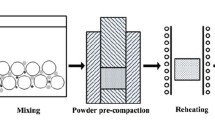

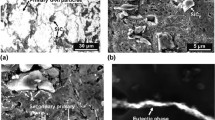

In this study, SiC particle reinforced Al2024 matrix composites were fabricated by powder thixoforming (PT). Meanwhile, 2024 alloys were fabricated by permanent mold cast (PMC) and PT, respectively, to reveal superiorities of PT technology over the traditional processing technologies and the resulting composite over the matrix alloy. The microstructures and mechanical properties of the three materials were comparatively investigated. The results indicated that both the PT materials possessed finer spheroidal primary particles and smaller eutectic concentration, but the PMC alloy comprised large equiaxed grains, continuously net-shaped eutectic structures, and many porosities. The mechanical properties of the PT alloy were significantly higher than those of the PMC alloy because of the enhanced compactness and work hardening, decreased eutectic concentration, and fine primary particles. The incorporation of SiCp to the PT alloy further brought improvements, the ultimate tensile strength (UTS), yield strength (YS), and hardness were increased by 29.3% (UTS = 388 MPa), 35% (YS = 297 MPa), and 46.8% (hardness = 122.6 HV), respectively. A strengthening model considering different strengthening mechanisms and SiCp failure was proposed and YS of composite could be exactly predicted.

Similar content being viewed by others

References

T. Varol, A. Canakci, and S. Ozsahin: Modeling of the prediction of densification behavior of powder metallurgy Al–Cu–Mg/B4C composites using artificial neural networks. Acta Metall. Sin. (Engl. Lett.) 28, 182 (2015).

A. Canakci and T. Varol: Microstructure and properties of AA7075/Al–SiC composites fabricated using powder metallurgy and hot pressing. Powder Technol. 268, 72 (2014).

A. Canakci, F. Arslan, and T. Varol: Effect of volume fraction and size of B4C particles on production and microstructure properties of B4C reinforced aluminium alloy composites. Mater. Sci. Technol. 29, 954 (2013).

T. Varol and A. Canakci: Synthesis and characterization of nanocrystalline Al 2024–B4C composite powders by mechanical alloying. Philos. Mag. Lett. 93, 339 (2013).

T. Varol and A. Canakci: The effect of type and ratio of reinforcement on the synthesis and characterization Cu-based nanocomposites by flake powder metallurgy. J. Alloys Compd. 649, 1066 (2015).

A. Canakci, F. Arslan, and T. Varol: Physical and mechanical properties of stir-casting processed AA2024/B4Cp composites. Sci. Eng. Compos. Mater. 21, 505 (2014).

C. Zhang, Z.Y. Cai, R.C. Wang, C.Q. Peng, K. Qiu, and N.G. Wang: Microstructure and thermal properties of Al/W-coated diamond composites prepared by powder metallurgy. Mater. Des. 95, 39 (2016).

C.M. Chen, C.C. Yang, and C.G. Chao: Thixocasting of hypereutectic Al–25Si–2.5Cu–1Mg–0.5Mn alloys using densified powder compacts. Mater. Sci. Eng., A 366, 183 (2004).

P.B. Li, T.J. Chen, S.Q. Zhang, and R.G. Guan: Research on semisolid microstructural evolution of 2024 aluminum alloy prepared by powder thixoforming. Metals 5, 547 (2015).

Y.S. Chen, T.J. Chen, S.Q. Zhang, and P.B. Li: Effects of processing parameters on microstructure and mechanical properties of powder-thixoforged 6061 aluminum alloy. Trans. Nonferrous Met. Soc. China 25, 699 (2015).

P.B. Li and T.J. Chen: Effect of SiCp volume fraction on the microstructure and tensile properties of SiCp/2024 Al-based composites prepared by powder thixoforming. J. Mater. Res. 31, 2850 (2016).

Z. Zhang and D.L. Chen: Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength. Scr. Mater. 54, 1321 (2006).

A. Sanaty-Zadeh: Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall–Petch effect. Mater. Sci. Eng., A 531, 112 (2012).

M.C. Flemings: Behavior of metal alloys in the semisolid state. Metall. Mater. Trans. B 22, 957 (1991).

D.H. Kirkwood: Semisolid metal processing. Int. Mater. Rev. 39, 173 (1994).

K. Sukumaran, K.K. Ravikumar, S.G.K. Pillai, T.P.D. Rajan, M. Ravi, R.M. Pillai, and B.C. Pai: Studies on squeeze casting of Al 2124 alloy and 2124-10% SiCp metal matrix composite. Mater. Sci. Eng., A 490, 235 (2008).

Y. Cai, M.J. Tan, G.J. Shen, and H.Q. Su: Microstructure and heterogeneous nucleation phenomena in cast SiC particles reinforced magnesium composite. Mater. Sci. Eng., A 282, 232 (2000).

T.J. Chen, L.K. Huang, X.F. Huang, Y. Ma, and Y. Hao: Effects of reheating temperature and time on microstructure and tensile properties of thixoforged AZ63 magnesium alloy. Mater. Sci. Technol. 30, 96 (2014).

G.K. Williamson and W.H. Hall: X-ray line broadening from filed aluminum and wolfram. Acta Metall. 1, 22 (1953).

G.K. Williamson and R.E. Smallman: The use of Fourier analysis in the interpretation of X-ray line broadening from cold-worked iron and molybdenum. Acta Crystallogr. 7, 574 (1954).

N.P. Cheng, S.M. Zeng, and Z.Y. Liu: Preparation, microstructures and deformation behavior of SiCP/6066Al composites produced by PM route. J. Mater. Process. Technol. 202, 27 (2008).

S-J. Hong, H-M. Kim, D. Huh, C. Suryanarayana, and B.S. Chun: Effect of clustering on the mechanical properties of SiC particulate-reinforced aluminum alloy 2024 metal matrix composites. Mater. Sci. Eng., A 347, 198 (2003).

H. Su, W.L. Gao, C. Mao, H. Zhang, H.B. Liu, J. Lu, and Z. Lu: Microstructures and mechanical properties of SiCp/2024 aluminum matrix composite synthesized by stir casting. Chin. J. of Nonferrous Met. 20, 217 (2010).

M. Emamy, M. Oliayee, and K. Tavighi: Microstructures and tensile properties of Al/2024–Al4Sr composite after hot extrusion and T6 heat treatment. Mater. Sci. Eng., A 625, 303 (2015).

R.J. Arsenault, L. Wang, and C.R. Feng: Strengthening of composites due to microstructural changes in the matrix. Acta Metall. Mater. 39, 47 (1991).

V.C. Nardone and K.M. Prewo: On the strength of discontinuous silicon carbide reinforced aluminum composites. Scr. Metall. 20, 43 (1986).

S.A. Sajjadi, H.R. Ezatpour, and M. Torabi Parizi: Comparison of microstructure and mechanical properties of A356 aluminum alloy/Al2O3 composites fabricated by stir and compo-casting processes. Mater. Des. 34, 106 (2012).

Z.L. Shi, J.M. Yang, J.C. Lee, D. Zhang, H.I. Lee, and R.J. Wu: The interfacial characterization of oxidized SiC(p)/2014 Al composites. Mater. Sci. Eng., A 303, 46 (2001).

R.J. Arsenault, N. Shi, C.R. Feng, and L. Wang: Localized deformation of SiC Al composites. Mater. Sci. Eng., A 131, 55 (1991).

H. Sekine and R. Chen: A combined microstructure strengthening analysis of SiCp/Al metal matrix composites. Composites 26, 183 (1995).

W.S. Miller and F.J. Humphreys: Strengthening mechanisms in particulate metal matrix composites. Scr. Metall. Mater. 25, 33 (1991).

N. Ramakrishnan: An analytical study on strengthening of particulate reinforced metal matrix composites. Acta Mater. 44, 69 (1996).

Z. Zhang and D.L. Chen: Contribution of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites. Mater. Sci. Eng., A 483–484, 148 (2008).

N. Hansen: The effect of grain size and strain on the tensile flow stress of aluminium at room temperature. Acta Metall. 25, 863 (1977).

C.A. Lewis and P.J. Withers: Weibull modelling of particle cracking in metal matrix composites. Acta Metall. Mater. 43, 3685 (1995).

M. Li, S. Ghosh, O. Richmond, H. Weiland, and T.N. Rouns: Three dimensional characterization and modeling of particle reinforced metal matrix composites part II: Damage characterization. Mater. Sci. Eng., A 266, 221 (1999).

W.J. Clegg, I. Horsfall, J.F. Mason, and L. Edwards: The tensile deformation and fracture of Al-“Saffil” metal–matrix composites. Acta Metall. 36, 2151 (1988).

J.C. Lee and K.N. Subramanian: Failure behaviour of particulate-reinforced aluminium alloy composites under uniaxial tension. J. Mater. Sci. 27, 5453 (1992).

M. Song and D.H. Xiao: Modeling the fracture toughness and tensile ductility of SiCp/Al metal matrix composites. Mater. Sci. Eng., A 474, 371 (2008).

C. González and J. Llorca: Prediction of the tensile stress-strain curve and ductility in Al/SiC composites. Scr. Mater. 35, 91 (1996).

H.K. Lee: A computational approach to the investigation of impact damage evolution in discontinuously reinforced fiber composites. Comput. Mech. 27, 504 (2001).

T.W. Clyne and P.J. Withers: An Introduction to Metal Matrix Composites (Cambridge University Press, New York, 1995); pp. 166–217.

M. Song, C.Q. Xie, and Y.H. He: Model of effects of particle failure on yield stress of SiC reinforced aluminum alloy composites. Chin. J. of Nonferrous Met. 20, 244 (2010).

T.S. Srivatsan, T.S. Sudarshan, and E.J. Lavernia: Processing of discontinuously-reinforced metal matrix composites by rapid solidification. Prog. Mater. Sci. 39, 317 (1995).

P.K. Rohatgi, S. Ray, R. Asthana, and C.S. Narendranath: Interfaces in cast metal-matrix composites. Mater. Sci. Eng., A 162, 163 (1993).

J.W. Ju and H.K. Lee: A micromechanical damage model for effective elastoplastic behavior of ductile matrix composites considering evolutionary complete particle debonding. Comput. Method. Appl. Mech. Eng. 183, 201 (2000).

ACKNOWLEDGMENTS

The authors wish to express thanks for the financial support provided by the Basic Scientific Fund of Gansu University (Grant No. G2014-07), the Program for New Century Excellent Talents of the University of China (Grant No. NCET-10-0023), and the Program for Hongliu Outstanding Youth of the Lanzhou University of Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, P., Chen, T. & Qin, H. The microstructure and mechanical properties of Al2024-SiCp composite fabricated by powder thixoforming. Journal of Materials Research 32, 2079–2091 (2017). https://doi.org/10.1557/jmr.2017.95

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.95