Abstract

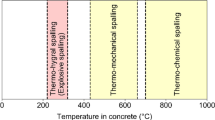

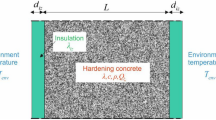

This paper describes results of NIST's experimental program that focuses on effects of elevated temperature exposure on residual mechanical properties of HPC. Residual mechanical properties were measured by heating the 102×204 mm cylinders to steady state thermal conditions at a target temperature, and loading them to failure after the specimens had cooled to room temperature. The test specimens were made of four HPC mixtures with water-to-cementitious material ratio (w/cm) ranging from 0.22 to 0.57, and room-temperature compressive strength at testing ranges from 51 MPa to 93 MPa. Two of the four HPC mixtures contained silica fume. The specimens were heated to a maximum core temperature of 450°C, at a heating rate of 5°C/min. Experimental results indicate that HPCs with higher original strength (lowerw/cm) and with silica fume retain more residual strength after elevated temperature exposure than those with lower original strength (higherw/cm) and without silica fume. The differences in modulus of elasticity are less significant. However, the potential for explosive spalling increased in HPC specimens with lowerw/cm and silica fume. An examination of the specimens' heating characteristics indicate that the HPC mixtures which experienced explosive spalling had a more restrictive process of capillary pore and chemically bound water loss than those which did not experience spalling.

Résumé

Cet article décrit les résultats du programme expérimental au NIST sur les effets que des températures élevées ont sur les propriétés résiduelles du BHP. Les propriétés mécaniques résiduelles ont été mesurées par la méthode suivante: des cylindres (102×204 mm) sont d'abord chauffés jusqu'à équilibre à une température choisie, puis stabilisés à température ambiante; enfin ils sont chargés en compression jusqu'à la rupture. Les échantillons étaient préparés à partir de quatre mélanges BHP avec des rapports eau/matériaux cimentaires (e/mc) entre 0.22 et 0.57. Les résistances à la compression de ces mélanges étaient entre 51 MPa et 93 MPa. Deux des mélanges contenaient de la fumée de silice. Les échantillons étaient chauffés jusqu'à une température interne de 450°C, à un taux de chauffage de 5°C/min. Les résultats expérimentaux indiquent que le BHP, avec une résistance à la compression initiale supérieure (e/c plus bas) et contenant de la fumée de silice, retient une résistance à la compression résiduelle plus élevée que les échantillons ayant une résistance à la compression plus basse (e/c plus élevé) et sans fumée de silice. Les différence entre les modules d'élasticité sont moins marquées. Par contre, la possibilité d'éclatement de surface est supérieure pour les échantillons avec le rapport e/mc plus bas et contenant de la fumée de silice. Un examen des caractéristiques thermiques des échantillons indique que les mélanges BHP qui explosent subissent une perte plus limitée d'eau capillaire et chimiquement absorbée en comparaison avec les échantillons sans éclatement de surface.

Similar content being viewed by others

References

Schneider, U., ‘Properties of Materials at High Temperatures— Concrete’, RILEM—Committee 44—PHT University of Kassel, Kassel, June 1985.

Phan, L. T., Carino, N. J., Duthinh, D. and Garboczi, E., ‘NIST International Workshop on Fire Performance of High Strength Concrete’, NIST, Gaithersburg, MD, February 13–14, 1997—Proceedings, NIST SP 919, Gaithersburg, Maryland, September 1997.

Castillo, C. and Durrani, A. J., ‘Effect of transient high temperature on high-strength concrete’,ACI Materials Journal 87 (1) (1990) 47–53.

Hert, K., ‘Danish investigations on silica fume concretes at elevated temperatures’, Proceedings of ACI 1991 Spring Convention, March 17–21.

Diederichs, U., Jumppanen, U. M. and Penttala, V. ‘Behavior of high strength concrete at high temperatures’, Helsinki University of Technology, Department of Structural Engineering, Report no. 92, 1989.

Hammer, T. A., ‘High-strength concrete phase 3: Compressive strength and E-modulus at elevated temperatures’, SP6 Fire Resistance, Report 6.1, SINTEF Structures and Concrete, February 1995.

Sullivan, P. J. E. and Shanshar, R., ‘Performance of concrete at elevated temperatures (as measured by the reduction in compressive strength)’,Fire Technology 28 (3) (Aug 1992) 240–250.

Abrams, M. S., ‘Compressive strength of concrete at temperatures to 1600F’, ACI SP 25, Temperature and Concrete, Detroit, Michigan, 1971.

Morita, T., Saito, H. and Kumagai, H., ‘Residual mechanical properties of high strength concrete members exposed to high temperature—Part 1. Test on material properties’, Summaries of Technical Papers of Annual Meeting, Architectural Institute of Japan, Niigata, August 1992.

Furumura, F., Abe, T. and Shinohara, Y., ‘Mechanical properties of high strength concrete at high temperatures’, Proceedings of the Fourth Weimar Workshop on High Performance Concrete: Material Properties and Design, Weimar, Germany, October 4th and 5th, 1995, 237–254.

Felicetti, R., Gambarova, P. G. Rosati, G. P., Corsi, F. and Giannuzzi, G., ‘Residual mechanical properties of HSC subjected to high-temperature cycles’, Proceedings, 4th International Symposium on Utilization of High-Strength/High-Performance Concrete, Paris, France, 1996, 579–588.

Noumowe, A. N., Clastres, P., Debicki, G. and Costaz, J.-L., ‘Thermal stresses and water vapor pressure of high performance concrete at high temperature’, Proceedings, 4th International Symposium on Utilization of High-Strength/High-Performance Concrete, Paris, France, 1996.

Phan, L. T., ‘Fire performance of High-Strength Concrete: A Report of the State-of-the-Art’, NISTIR 5934, National Institute of Standards and Technology, Gaithersburg, Maryland, December 1996.

Bentz, D. P. ‘Fibers, percolation, and spalling of high performance concrete’,ACI Materials Journal 97 (3) (May–June, 2000).

Author information

Authors and Affiliations

Additional information

Editorial Note Dr. Long Phan is a RILEM Senior Member. He participates in the work of RILEM TC 129-MHT Test methods for Mechanical properties of concrete at High Temperature. The NIST is a RILEM Titular Member.

Rights and permissions

About this article

Cite this article

Phan, L.T., Lawson, J.R. & Davis, F.L. Effects of elevated temperature exposure on heating characteristics, spalling, and residual properties of high performance concrete. Mat. Struct. 34, 83–91 (2001). https://doi.org/10.1007/BF02481556

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02481556