Abstract

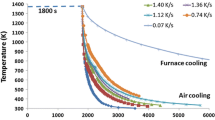

The structures of four 0.15 pct carbon steels containing vanadium, nitrogen, and aluminum separately and together were studied systematically, with the help of transmission electron microscopy, by cooling suitable steels at four different rates ranging from 120 °C/min to 3.6 °C/ min from temperatures giving a common austenite grain size of 35 μm. Except for the steel containing only vanadium and that containing only aluminum and nitrogen cooled at the fastest rate used, the observed microstructures were all essentially mixtures of polygonal ferrite and expected amounts for pearlite. For all the steels studied, except the one containing aluminum and nitrogen, it was found that general precipitation was more common than interphase precipitation, although the extent of the latter increased at lower cooling rates. Moreover, in some cases, both general and interphase precipitation were present in the same area. The presence of aluminum was observed to enhance the formation of interphase precipitates at all cooling rates, and the spacing between parallel rows of precipitates increased as the cooling rate was decreased. The dislocation density was high at all cooling rates in all the steels, but it was found to decrease with decreasing cooling rates. Very fine precipitates were found in all the steels, except the steel containing aluminum and nitrogen. At the fast cooling rates, the segregation of vanadium and interstitial elements, which led to locally lower transformation temperatures and higher supersaturations, resulted in clusters of fine particles of vanadium carbonitride, V(C, N). At the slower cooling rates, all the steels showed severe heterogeneity in precipitate morphology which was more pronounced in the steel containing aluminum and nitrogen, while a needlelike morphology of V(C, N) precipitate was occasionally found in steels containing either vanadium and nitrogen or vanadium, nitrogen, and aluminum. As the cooling rate decreased, particle coarsening and growth occurred, causing a reduction in the number of particles/unit area. The coarsening rate of V(C,N) in the presence of aluminum is considerably lower than that of vanadium carbide, VC, or of V(C, N) in the absence of aluminum. Because of the unfavorable precipitation kinetics, any aluminum nitride (A1N) formed during cooling did not nucleate separately but was deposited on the pre-existing A1N particles, thus causing them to be coarsened very rapidly with decreasing cooling rate.

Similar content being viewed by others

References

E. Tekin and P.M. Kelly:Precipitation from Iron-Based Alloys, AIME Conf. Proc, Gordon and Breach, New York, NY, 1965.

E. Tekin and P.M. Kelly:J. Iron Steel Inst., 1965, vol. 203, p. 715.

E. Smith:Acta Metall., 1966, vol. 14, p. 583.

J.H. Woodhead and D. Webster:J. Iron Steel Inst., 1969, vol. 207, p. 51.

A.T. Davenport, F.G. Berry, and R.W.K. Honeycombe:Met. Sci. J., 1968, vol. 2, p. 104.

F.G. Berry, A.T. Davenport, and R.W.K. Honeycombe:Mechanism of Phase Transformations in Crystalline Solid, Institute of Metals, 1969, Monogr. No. 33, p. 288.

A.T. Davenport and R.W.K. Honeycombe:Proc. R. Soc, 1971, vol. A322, p. 191.

H.C. Sutton and J.A. Whiteman:J. Iron Steel Inst., 1971, vol. 209, p. 220.

M. Tanino, T. Nishida, T. Oaka, and K. Yoshikawa:Proc. Symp. on Micrometallurgy, Jamshedpur, India, 1965, p. 77.

S. Niltawach: Ph.D. Thesis, University of Sheffield, Sheffield, England, 1977.

M.M.A. Bepari: Ph.D. Thesis, University of Sheffield, Sheffield, England, 1981.

M.M.A. Bepari:Metall. Trans. A, 1989, vol. 20A, pp. 13–16.

M.M.A. Bepari:Mater. Sci. Technol., 1989, vol. 5, pp. 13–19.

M.M.A. Bepari:Mater. Sci. Technol., 1990, vol. G, pp. 338–48.

S.R. Keown and D.J. Dyson:J. Iron Steel Inst., 1966, vol. 204, p. 832.

H.G. Suzuki and M. Tanino:Trans. Iron Steel Inst. Jpn., 1972, vol. 12, p. 217.

K. Aoki and M. Tanino:Yawata Technical Report, 1966, vol. 225, pp. 6550 and 6678.

M. Tanino, H.G. Suzuki, and K. Aoki:Trans. Jpn. Inst. Met., 1968, vol. 9, p. 393.

J.M. Gray and R.B.G. Yeo:Trans. ASM, 1968, vol. 61, p. 255.

W.B. Morrison:J. Iron Steel Inst., 1963, vol. 201, p. 317.

M. Tanino and K. Aoki:Trans. Iron Steel Inst. Jpn., 1968, vol. 8, p. 337.

S. Freeman:Effect of Second-Phase Particles on the Mechanical Properties of Steel, The Iron and Steel Institute, London, 1971, pp. 152 and 205.

T.N. Baker:J. Iron Steel Inst., 1973, vol. 211, p. 502.

T.N. Baker and A.J. Lapointe:Proc. EMAG 77, Institute of Physics, London, 1977, p. 195.

T.N. Baker:Sci. Prog., Oxford, 1978, vol. 65, p. 493.

Author information

Authors and Affiliations

Additional information

Formerly with the Department of Metallurgy, The University of Sheffield, Sheffield, England

Rights and permissions

About this article

Cite this article

Bepari, M.M.A. Structure of continuously cooled low-carbon vanadium steels. Metall Trans A 21, 2839–2855 (1990). https://doi.org/10.1007/BF02647205

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02647205