Abstract

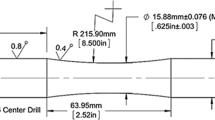

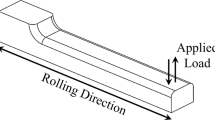

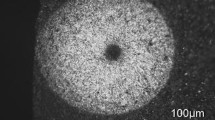

Cantilever fatigue specimens with a reduced section and rounded tensionside corners were machined from SAE 8719 steel (containing 0.19% C, 1.06% Mn, 0.52% Cr, 0.50% Ni and 0.17% Mo) bars. The specimens were plasma and gas carburized to surface carbon of 0.82% to 0.84%, surface hardness of 65 HRC, and case depths of 1.2 mm at 50 HRC. Some specimens were direct quenched from 850° C after carburizing and some were reheated to 850° C and quenched. All specimens were tempered at 150° C. Excellent high cycle bending fatigue resistance correlated with fine austenitic grain size and low retained austenite. The highest fatigue limit, 1650 MPa (240 ksi), was measured in reheated gas carburized specimens with an austenitic grain size of ASTM No. 11 and surface retained austenite content of about 22%. Reheating reduced the austenite grain size of the carburized specimens and resulted in improved fatigue resistance for both the plasma and gas carburized specimens.

Similar content being viewed by others

References

G. Parish:The Influence of Microstructure on the Properties of Case-Carburized Components, ASM International, Metals Park, Ohio, 1980.

Case-Hardened Steels: Microstructural and Residual Stress Effects, D.E. Diesburg, ed., TMS, Warrendale, Pennsylvania, 1984.

J. Zurn, C. Razim, and J. Grosch: “The Effect of Residual Stress in Case Hardening,” inHeat Treatment and Surface Engineering, G. Krauss, ed., ASM International, 1988, pp. 279–283.

G. Krauss: “The Microstructure and Fracture of Carburized Steel,”Metallurgical Transactions A, vol. 9A, 1978, pp. 1527–1535.

C. Razim: “Uber den Einfluss von Restaustenit auf das Festigkeitsverhalten Einsatzgeharteter Probekorper bei Schwingender Beanspruchung,”Hartere:-Technishe Mitteilungen, vol. 23, 1968, pp. 1–8.

H. Brandis and W. Schmidt: “Contribution to the Influence of Retained Austenite on the Mechanical Properties of Case-Hardened Steels,” inCase-Hardened Steels, Microstructures and Residual Stress Effects, D.E. Diesburg, ed., TMS, Warrendale, Pennsylvania, 1984, pp. 189–200.

K.D. Jones and G. Krauss: “Effects of High-Carbon Specimen Corners on Microstructure and Fatigue of Partial Pressure Carburized Steels,” inHeat Treatment ’79, The Metals Society, London, 1980, pp. 188–193.

R. Chatterjee-Fischer: “Internal Oxidation During Carburizing and Heat Treating,”Metallurgical Transactions A, vol. 9A, 1978, pp. 1553–1560.

C.A. Apple and G. Krauss: “Microcracking and Fatigue in a Carburized Steel,”Metallurgical Transactions, vol. 4, 1973, pp. 1195–1200.

G. Krauss: “The Relationship of Microstructure to Fracture Morphology and Toughness of Hardened Hypereutectoid Steels,” inCase Hardened Steels: Microstructural and Residual Stress Effects, D.E. Diesburg, ed., TMS, Warrendale, Pennsylvania, 1984, pp. 33–58.

H. Streng, C. Razim, and J. Grosch: “Diffusion of Hydrogen During Carburization and Tempering,” inHeat Treatment and Surface Engineering, G. Krauss, ed., ASM International, 1988, pp. 313–317.

J.B. Kelly and G. Krauss: “Effect of Chromium and Microstructure on the Bending Fatigue of 0.75Mo-1.8Ni-0.80C Steels,” inProceedings of 4th International Congress on Heat Treatment of Materials, Berlin, 1985, vol. 1, pp. 147–163.

M.A. Zaccone, J.B. Kelley, and G. Krauss: “Fatigue and Strain-Hardening of High-Carbon Martensite-Austenite Composite Microstructures,” inHeat Treatment 87, The Institute of Metals, London, 1988, pp. 93–101.

M.A. Zaccone and G. Krauss: “Fatigue and Strain Hardening of Simulated Case Microstructures in Carburized Steels,” inHeat Treatment and Surface Engineering, G. Krauss, ed., ASM International, Metals Park, Ohio, 1988, pp. 285–290.

D.E. Diesburg and G.T. Eldis: “Fracture Resistance of Various Carburized Steels,”Metallurgical Transactions A, vol. 9A, 1978, pp. 1561–1570.

R.A. DePaul: “High Cycle and Impact Fatigue Behavior of Some Carburized Gear Steels,”Metals Engineering Quarterly, vol. 10, 1970, pp. 25–29.

L. Magnusson and T. Ericsson: “Initiation and Propagation of Fatigue Cracks in Carburized Steel,” inHeat Treatment 79, The Metals Society, London, 1980, pp. 202–206.

H. Brugger: “Schlagbeigeversuch zur Beurteilung Einsatzgeharteter Stahle,”Schweizer Archiv fur Augewandte Wissenchaft und Technik, vol. 36, 1970, pp. 219–229.

T.B. Cameron and D.E. Diesburg: “The Significance of the Impact Fracture Strength of a Carburized Steel,” inCase-Hardened Steels: Microstructural and Residual Stress Effects, D.E. Diesburg, ed., TMS, Warrendale, Pennsylvania, 1984, pp. 17–32.

H.K. Obermeyer and G. Krauss: “Toughness and Intergranular Fracture of a Simulated Carburized Case in EX-24 Type Steel,”Journal of Heat Treating, vol. 1, no. 3, 1980, pp. 31–39.

T. Ando and G. Krauss: “The Effect of Phosphorus Content on Grain Boundary Cementite Formation in AISI 52100 Steel,”Metallurgical Transactions A, vol. 12A, 1981, pp. 1283–1290.

Author information

Authors and Affiliations

Additional information

This paper has been published in “Carburizing: Processing and Performance 1989,” ASM INTERNATIONAL, Materials Park, OH, USA.

Rights and permissions

About this article

Cite this article

Pacheco, J.L., Krauss, G. Microstructure and high bending fatigue strength in carburized steel. J. Heat Treating 7, 77–86 (1989). https://doi.org/10.1007/BF02833192

Issue Date:

DOI: https://doi.org/10.1007/BF02833192