Abstract

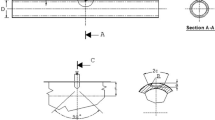

The fatigue crack growth rate and fracture toughness tests of type 304 stainless steel were studied over a temperature range of −162°C to room temperature. Girth weld metal specimens were fabricated using a combination of gas-tungsten-arc-welding and shielded-metal-arc-welding. The seam weld metal was made with submerged arc welding. Fatigue crack growth rate tests were conducted using compact tension specimens in accordance with ASTM E647. Fracture toughness was evaluated through CTOD tests with three point bend specimens. The CTOD values were affected by crack orientation with respect to the rolling direction, but orientation had no influence on fatigue crack growth rates. The fatigue crack growth rates and the CTOD values decreased with decreasing test temperature.

Similar content being viewed by others

References

R. E. Avery and D. Parsons,Weld. J.,74, 45 (1995).

K. Mukai, K. Hoshino and T. Fujioka,Tetsu-to-Hagane 65, 1756 (1979).

K. Tsuzaki, E. Nakanishi, T. Maki and I. Tamura,ISIJ 23, 834 (1983).

W. J. Mills,Int. Mater. Rev. 42, 45 (1997).

T. Nakamura, M. Tominaga, H. Murase and Y. Nishiyama,Tetsu-to-Hagane 68, 471 (1982).

J. Gordon and A. Hanson,An Introduction to Stainless Steel, p. 137, ASM, Metals Park, OH (1965).

Y. X. Zhao, Q. Gao and J. N. Wang,Fatigue Fract. Eng. Mater. Struct. 22, 469 (1999).

A. Nishimura, R. L. Tobler, H. Tamura, S. Imagawa and J. Yamamoto,Fusion Eng. Des. 42, 425 (1998).

D. T. Read, H. I. Mchenry, P. A. Steinmeyer and R. D. Thomas,Weld. J. 59, 104 (1980).

P. K. Liaw and W. A. Logsdon,Eng. Fract. Mech. 22, 585 (1985).

D. A. Jones,Principles and Prevention of Corrosion, p. 291, Macmillian Publ. Co., New York, NY (1992).

J. E. Strawley,Int. J. Fract. 12, 475 (1976).

P. C. Paris, M. P. Gomez and W. E. Anderson,The Trend in Engineering 13, 9 (1961).

R. Ogawa and J. W. Moris,ASTM STP 857, 47 (1985).

B. I. Verkin, N. M. Grinberg, V. A. Serdyuk and L. F. Yakovenko,Mater. Sci. Eng. 58, 145 (1983).

T. Kawasaki, S. Nakanishi, Y. Sawaki. K. Hatanaka and T. Yokobori,Eng. Frac. Mech. 7, 465 (1975).

Fracture Mechanics Toughness Tests, British Standard BS 7448, Part 1 (1991).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Baek, JH., Kim, CM., Kim, WS. et al. Fatigue crack growth and fracture toughness properties of 304 stainless steel pipe for LNG transmission. Met. Mater. Int. 7, 579–585 (2001). https://doi.org/10.1007/BF03179257

Issue Date:

DOI: https://doi.org/10.1007/BF03179257