Abstract

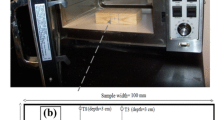

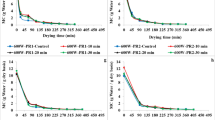

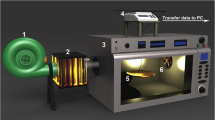

This paper investigated the impact of microwave-assisted drying on the energy consumption, drying rate, surface temperature, drying time, static bending properties, and quality of dried rubberwood (Heavea brasiliensis) using different scenarios of combined microwave and convective air drying. Combined microwave and convective drying experiments were performed at frequencies of 2.45 ± 0.05 GHz and microwave power of 4.8 kW, air drying temperatures of 30, 50, and 70 °C, and air drying velocity of 5.0 m/s using a multifeed microwave-convection hot air and continuous belt system (CMCB). The test results showed that rubberwood drying in a microwave system with multiple wave feeding and convection heating together with a conveyor in a hybrid system reduced the moisture of rubberwood from 70% to an average of approximately 20%. In addition, the most suitable conditions for the experiment were drying at an air temperature of 30 °C for 30 min and then in a microwave at 30 °C, compared to 30 °C for 30 min and then turning on the microwave at temperatures of 50 and 70 °C. The minimum energy consumption for drying with this method was 16.3 kWh. The results also indicated that the end quality of rubberwood samples dried under microwave-assisted drying was similar to that of conventional drying but better than that of rubberwood samples dried under combined microwave and air drying.

Similar content being viewed by others

Availability of data and material (data transparency)

None.

Code availability (software application or custom code)

None.

References

British Standards Institution (1957) BS 373: methods of testing small clear specimens of timber is classified in these ICS categories: 79.040 Wood, sawlogs and sawn timber. Pilsen, Czech Republic

Charoenvai S, Yingyuen W, Jewyee A, Rattandecho P, Vongpradubchai S (2013) Comparative evaluation on product properties and energy consumption of single microwave dryer and combination of microwave and hot air dryer for durian peel particleboards. Energy Procedia 34:479–492

Chena L, Yu Z, Xu H, Wan K, Liao Y, Ma X (2019) Microwave-assisted co-pyrolysis of Chlorella vulgaris and wood sawdust using different additives. Bioresour Technol 273:34–39

Dubey MK, Janowiak J, Mack R et al (2016) Comparative study of radio-frequency and microwave heating for phytosanitary treatment of wood. Eur J Wood Prod 74:491–500

Hansson L, Antti AL (2003) The effect of microwave drying on Norway spruce woods strength: a comparison with conventional drying. J Mater Process Technol 141:41–50

Hansson L, Antti AL (2006) The effect of drying method and temperature level on the hardness of wood. J Mater Process Technol 171:467–470

He Z, Qian J, Qu L, Wang Z, Yi S (2019) Simulation of moisture transfer during wood vacuum drying. Results Phys 12:1299–1303

Henin JM, Leyman M, Bauduin A et al (2014) Phytosanitary treatment of European pallets by microwave: developing a program to ensure compliance with ISPM 15 and monitoring its efficacy on the house longhorn beetle (Hylotrupes bajulus L.). Eur J Wood Prod 72:623–633

Holtz E, Ahrne L, Rittenauer M, Rasmuson A (2010) Influence of dielectric and sorption properties on drying behaviour and energy efficiency during microwave convective drying of selected food and non-food inorganic materials. J Food Eng 97:144–153

Johansson A, Fyhr C, Rasmuson A (1997) High temperature convective drying of wood chips with air and superheated steam. Int J Heat Mass Transf 40(12):2843–2858

Kowalskii SJ, Rajewska K (2009) Effectiveness of hybrid drying. Chem Eng Process 48:1302–1309

Lv H-F, Ma X-X, Zhang B et al (2017) Microwave-vacuum drying of round bamboo: a study of the physical properties. Constr Build Mater 211:44–51

Metaxas AC (1991) Microwave heating. J Microw Power Electromag Energy 237–247

Ouertani S, Koubaa A, Azzouz S et al (2018) Microwave drying kinetics of jack pine wood: determination of phytosanitary efficacy, energy consumption, and mechanical properties. Eur J Wood Prod 76:1101–1111

Prommas R, Rattanadecho P, Jindarat W (2012) Energy and exergy analyses in drying process of non-hygroscopic porous packed bed using a combined multi-feed microwave-convective air and continuous belt system (CMCB). Int Commun Heat Mass Transfer 39:242–250

Ratnasingam J, Grohmann R, Scholz F (2010) Drying quality of rubberwood: an industrial perspective. Eur J Wood Prod 68:115–116

Rattanadecho P (2006) The simulation of microwave heating of wood using a rectangular waveguide: influence of frequency and sample size. Chem Eng Sci 61:4798–4811

Vongpradubchai S, Rattanadecho P (2009) The microwave processing of wood using a continuous microwave belt drier. Chem Eng Process 48:997–1003

Acknowledgements

The authors gratefully thank you for Thailand Government Budget Grant and PMU B (Contract No. B05F630092) provided financial support for this study.

Funding

This research was financially supported by the Thailand Research Fund (TRF) under RTA 5980009 (Funder ID: http://doi.org/10.13039/501100004396).

Author information

Authors and Affiliations

Contributions

All authors whose names appear on the submission as follows: (1) made substantial contributions to the conception or design of the work; or the acquisition, analysis, or interpretation of data; or the creation of new software used in the work; (2) drafted the work or revised it critically for important intellectual content; (3) approved the version to be published; and (4) agreed to be accountable for all aspects of the work in ensuring that questions related to the accuracy or integrity of any part of the work are appropriately investigated and resolved.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vongpradubchai, S., Makul, N. & Rattanadecho, P. Influence of the microwave-accelerated process on the drying kinetics, mechanical properties and surface appearance of rubberwood (Heavea brasiliensis). Eur. J. Wood Prod. 80, 395–407 (2022). https://doi.org/10.1007/s00107-021-01766-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-021-01766-3