Abstract

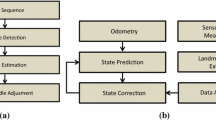

This paper proposes the development of a monitoring system to be applied for a production system (bucket-wheel excavator). The system is based on a multisensor-based object detection system. The main objective of the detection system is to obtain—in real time—reliable decisions on the presence of large stones in the transported overburden. The highest possible detection rate and the lowest possible false alarm rate should be achieved to avoid disturbances or failures of the production process. Due to the complexity of the considered production system, different physical effects are taken into account. The detection system consists of two detection modules (acceleration and laser scanner module), a plausibility module (weightometer module), and a fusion module. The acceleration module consists of five acceleration sensors. The acceleration signals are individually undergone preprocessing, feature extraction, and classification processes. The preliminary decisions of different sensor channels are fused to obtain statements about the presence of large stones. In the laser scanner module, the signal is prefiltered, filtered, validated, and classified in order to detect excavated stones. The weightometer module is based on two load cells signals. It is developed to approve the plausibility of the positive statements of the acceleration module. The fusion module is developed in order to synchronize and combine the output statements of different modules to obtain the production system state with respect to the presence of an object. The detection system is developed based on the acquired knowledge from the analysis of the production process and the analysis of the acquired data during the production process. The designed system has been implemented using standard industrial hardware. The testing results to be reported show that the system requirements can be fulfilled.

Similar content being viewed by others

References

Al-Badour F, Sunar M, Cheded L (2011) Vibration analysis of rotating machinery using time-frequency analysis and wavelet techniques. Mech Syst Sig Process 25(6):2083–2101

Al-Shrouf L (2014) Development and implementation of a reliable decision fusion and pattern recognition system for object detection and condition monitoring. Ph.D. thesis, University of Duisburg-Essen

Al-Shrouf L, Saadawia M, Söffker D (2013) Improved process monitoring and supervision based on a reliable multi-stage feature-based pattern recognition technique. Inf Sci 259:282–294

Al-Shrouf L, Söffker D (2012) Feature-based multi sensor fusion system for object and stone recognition. Internal final report (in german). Chair of Dynamics and Control. University of Duisburg-Essen, Duisburg, Germany

Banerjee T, Das S (2012) Multi-sensor data fusion using support vector machine for motor fault detection. Inf Sci 217:96–107

Bhatnagar G, Wu Q, Raman B (2013) Discrete fractional wavelet transform and its application to multiple encryption. Inf Sci 223:297–316

Celik N, Gagarin R, Youn H, Iskander M (2011) A noninvasive microwave sensor and signal processing technique for continuous monitoring of vital signs. IEEE Antennas Wirel Propag Lett 10:286–289

Feng Z, Liang M, Chu F (2013) Recent advances in time-frequency analysis methods for machinery fault diagnosis: a review with application examples. Mech Syst Sig Process 38:165–205

Gao R, Yan R (2011) Wavelets Theory and Applications for Manufacturing. Springer New York, Secaucus, USA

Gramfort A, Strohmeier D, Haueisen J, Hämäläinen M, Kowalsk M (2013) Time-frequency mixed-norm estimates: Sparse M/EEG imaging with non-stationary source activations. NeuroImage 70:410–422

Hu H (2011) Augmented DT-CWT feature based classification using regularized neighborhood projection discriminant analysis for face recognition. Pattern Recogn 44(3):519–531

Lou KN, Lin CJ (1997) An intelligent sensor fusion system for tool monitoring on a machining centre. Int J Adv Manuf Technol 13(8):556–565

Nieß T (2009) Automatic metal and stone detection on bucket-wheel excavators used in RWE power AGs opencast lignite mines. World Min 61:226–233

Petrich F, Köhler U (2005) Stone detection and stone excavation—results and current directions of work with regard to technical stone handling in lusatian opencast mines. World Min 57:412–420

Saß J, Matare F, Schubert T (2007) Metallsuchgerät und Steinerfassungssystem, Bagger 258 und 261 Tagebau Garzweiler, Bagger 259, 260 und 290 Tagebau Hambach, Bagger 255 Tagebau Inden, Siemens AG

Su H, Xi W, Chong KT (2007) Vibration signal analysis for electrical fault detection of induction machine using neural networks. In: Information Technology Convergence, 2007. ISITC 2007. International Symposium on, Jeonju, Korea, pp 188– 192

Winkler J (2011) Algorithmenentwicklung zur Steuerung eines Förderprozesses. Diploma thesis. University of Duisburg-Essen, Duisburg, Germany

Wu F, Meng G (2006) Feature extraction based on the 3d spectrum analysis of acoustic signals to identify rotor malfunction. Int J Adv Manuf Technol 28(11-12):1146–1151

Yella S, Ghiamati S, Dougherty M (2009) Condition monitoring of wooden railway sleepers using time-frequency techniques and pattern classification. In: Systems, Man and Cybernetics, 2009. SMC 2009. IEEE International Conference on, Texas, USA, pp 4164–4169

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al-Shrouf, L., Szczepanski, N. & Söffker, D. Online feature-based multisensor object detection system for bucket-wheel excavators. Int J Adv Manuf Technol 82, 1213–1226 (2016). https://doi.org/10.1007/s00170-015-7375-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7375-9