Abstract

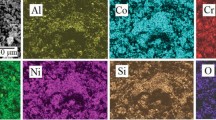

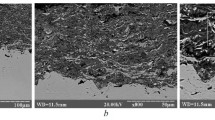

NiCrAlY coatings were deposited on superalloy GH4169 by electrospark deposition technique. Influences of the depositing parameters (100 V/40 μF, 100 V/80 μF, 100 V/120 μF, 150 V/40 μF, 150 V/80 μF, 150 V/120 μF) on the microstructure and the properties of the coatings were experimentally investigated. Results show that the depositing parameters affect defect density and consequent properties of coatings. The deposition voltage has greater influences on the deposition velocity and on the properties of the coatings than the deposition capacity. The weight gain per area of the coatings deposited under 150 V increases faster than that under 100 V. The coating deposited under 100 V/40 μF has the minimum defect density and the best properties.

Similar content being viewed by others

References

Kudryashov AE, Potanin AY, Lebedev DN, Sukhorukova IV, Shtansky DV, Levashov EA (2016) Structure and properties of Cr-Al-Si-B coatings produced by pulsed electrospark deposition on a nickel alloy. Surf Coat Technol 285:278–288. https://doi.org/10.1016/j.surfcoat.2015.11.052

Podchernyaeva IA, Panasyuk AD, Teplenko MA, Podol’skii VI (2000) Protective coatings on heat-resistant nickel alloys (review). Powder Metall Met Ceram 39:434–444. https://doi.org/10.1023/A:1011358221085

Pimentel JV, Danek M, Polcar T, Cavaleiro A (2014) Effect of rough surface patterning on the tribology of W-S-C-Cr self-lubricant coatings. Tribol Int 69:77–83. https://doi.org/10.1016/j.triboint.2013.09.004

Xin B, Yu Y, Zhou J, Wang L, Ren S (2017) Effect of copper molybdate on the lubricating properties of NiCrAlY laser clad coating at elevated temperatures. Surf Coat Technol 313:328–336. https://doi.org/10.1016/j.surfcoat.2017.01.098

Monceaua D, Oquaba D, Estournesb C, Boidota M, Selezneffa S, Thebaulta Y (2009) Pt-modified Ni aluminides, MCrAlY-base multilayer coatings and TBC systems fabricated by Spark Plasma Sintering for the protection of Ni-base superalloys. Surf Coat Technol 204(6):771–778. https://doi.org/10.1016/j.surfcoat.2009.09.054

Wang J, Chen M, Cheng Y, Yang L, Bao Z, Liu L, Zhu S, Wang F (2017) Hot corrosion of arc ion plating NiCrAlY and sputtered nanocrystalline coatings on a nickel-based single-crystal superalloy. Corros Sci 123:27–39. https://doi.org/10.1016/j.corsci.2017.04.004

Shen M, Zhao P, Gu Y, Zhu S, Wang F (2015) High vacuum arc ion plating NiCrAlY coatings: microstructure and oxidation behavior. Corros Sci 94:294–304. https://doi.org/10.1016/j.corsci.2015.02.032

Agarwal A, Dahotre NB, Sudarshan TS (2013) Evolution of interface in pulsed electrode deposited titanium diboride on copper and steel. Surf Eng 15:27–32. https://doi.org/10.1179/026708499322911601

Agarwal A, Dahotre NB (1999) Synthesis of boride coating on steel using high energy density rrocesses: comparative study of evolution of microstructure. Mater Charact 42(1):31–34. https://doi.org/10.1016/S1044-5803(98)00054-0

Li Z, Gao W, Kwok P, Li S, He Y (2010) Electro-spark deposition coatings for high temperature oxidation resistance. High Temp Mater Process 19(6):443–458. https://doi.org/10.1515/HTMP.2000.19.6.443

Zamulaeva EI, Levashov EA, Sviridova TA, Shvyndina NV, Petrzhik MI (2013) Influence of topography on plasma treated titanium surface wettability. Surf Coat Technol 235(22):447–453. https://doi.org/10.1016/j.surfcoat.2013.08.001

Cadney S, Brochu M (2008) Formation of amorphous Zr41. 2Ti13. 8Ni10 Cu12. 5Be22. 5 coatings via the ElectroSpark Deposition processIntermetallics. Intermetallics 16(4):518–523. https://doi.org/10.1016/j.internet

Frangini S, Masci A (2010) A study on the effect of a dynamic contact force control for improving electrospark coating properties. Surf Coat Technol 204(16–17):2613–2623. https://doi.org/10.1016/j.surfcoat.2010.02.006

Ribalco AV, Sahin O, Korkmaz K (2009) A modified electrospark alloying method for low surface roughness. Surf Coat Technol 203(23):3509–3515. https://doi.org/10.1016/j.surfcoat2009.05.002

Luo C, Dong SJ, Xiang X (2008) Microstructure and properties of TiC coating by vibrating electrospark deposition. Key Eng Mater 180:373–374. https://doi.org/10.4028/www.scientific.net/KEM.373-374.180

Xie Y-j, Wang M-c (2006) Epitaxial MCrAlY coating on a Ni-base superalloy produced by electrospark deposition. Surf Coat Technol 201:3564–3570. https://doi.org/10.1016/j.surfcoat.2006.08.107

Wang M-c, Wang W-f, Xie Y-j, Zhang J (2010) Electro-spark epitaxial deposition of NiCoCrAlYTa alloy on directionally solidified nickel-based superalloy. Trans Nonferrous Metals Soc China 20:795–802. https://doi.org/10.1016/S1003-6326(09)60216-8

Heard DW, Brochu M (2010) Development of a nanostructure microstructure in the Al-Ni system using the electrospark deposition process. J Mater Process Technol 210:892–898. https://doi.org/10.1016/j.jmatprotec.2010.02.001

Hintermann HE (1993) Characterization of surface coatings by the scratch adhesion test and by indentation measurements. Fresenius J Anal Chem 346:45–52. https://doi.org/10.1007/BF00321380

Johnson RN, Sheldon GL (1986) Advances in the electrospark deposition coating process. J Vac Sci Technol A 4(6):2740–2746. https://doi.org/10.1116/1.573672

Chen Z, Zhou Y (2006) Surface modification of resistance welding electrode by electro-spark deposited composite coatings: part I. Coating characterization. Surf Coat Technol 201(3-4):1503–1510. https://doi.org/10.1016/j.surfcoat.2006.02.015

Acknowledgements

This work is supported by “863” project (No. 2015AA034303). The authors also thank Lin Yang (School of Aerospace, Mechanical and Mechatronic Engineering School of Naval Architecture and Ocean Engineering, the University of Sydney, NSW 2006, Australia) for English polishing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cao, G., Wang, Y. & Tang, G. Properties of NiCrAlY coatings fabricated on superalloy GH4169 by electrospark deposition. Int J Adv Manuf Technol 96, 1787–1793 (2018). https://doi.org/10.1007/s00170-017-1162-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1162-8