Abstract

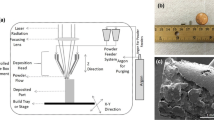

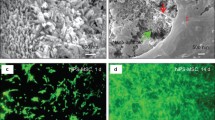

Direct metal laser sintering can produce porous Ti–6Al–4V orthopedic and dental implants. The process requires reduced resources and time and can provide greater structural control than machine manufacturing. Implants in bone are colonized by mesenchymal stem cells (MSCs), which can differentiate into osteoblasts and contribute to osseointegration. This study examined osteoblast differentiation and matrix mineralization of human MSCs cultured on laser-sintered Ti–6Al–4V constructs with varying porosity and at different time scales. 2D solid disks and low, medium and high porosity (LP, MP, and HP) 3D constructs based on a human trabecular bone template were laser sintered from Ti–6Al–4V powder and further processed to have micro- and nanoscale roughness. hMSCs exhibited greater osteoblastic differentiation and local factor production on all 3D porous constructs compared to 2D surfaces, which was sustained for 9 days without use of exogenous factors. hMSCs cultured for 8 weeks on MP constructs in osteogenic medium (OM), OM supplemented with BMP2 or collagen-coated MP constructs in OM exhibited bone-like extracellular matrix mineralization. Use of bio-inspired porosity for the 3D architecture of additively manufactured Ti–6Al–4V enhanced osteogenic differentiation of hMSCs beyond surface roughness alone. This study suggests that a 3D architecture may enhance the osseointegration of orthopedic and dental implants in vivo.

Similar content being viewed by others

References

Ruffo M, Tuck C, Hague R (2006) Cost estimation for rapid manufacturing—laser sintering production for low to medium volumes. Proc Inst Mech Eng B J Eng Manuf 220:1417–1427

Frazier WE (2014) Metal additive manufacturing: a review. J Mater Eng Perform 23:1917–1928

Yang J, Cai H, Lv J, Zhang K, Leng H, Sun C, Wang Z, Liu Z (2014) In vivo study of a self-stabilizing artificial vertebral body fabricated by electron beam melting. Spine 39:E486–E492

Stübinger S, Mosch I, Robotti P, Sidler M, Klein K, Ferguson SJ, von Rechenberg B (2013) Histological and biomechanical analysis of porous additive manufactured implants made by direct metal laser sintering: a pilot study in sheep. J Biomed Mater Res B Appl Biomater 101:1154–1163

Mangano F, Luongo F, Shibli JA, Anil S, Mangano C (2014) Maxillary overdentures supported by four splinted direct metal laser sintering implants: a 3-year prospective clinical study. Int J Dent 2014:252343

Asaoka K, Kuwayama N, Okuno O, Miura I (1985) Mechanical properties and biomechanical compatibility of porous titanium for dental implants. J Biomed Mater Res 19:699–713

Karageorgiou V, Kaplan D (2005) Porosity of 3D biomaterial scaffolds and osteogenesis. Biomaterials 26:5474–5491

Van der Stok J, Van der Jagt OP, Amin Yavari S, De Haas MFP, Waarsing JH, Jahr H, Van Lieshout EMM, Patka P, Verhaar JAN, Zadpoor AA, Weinans H (2013) Selective laser melting-produced porous titanium scaffolds regenerate bone in critical size cortical bone defects. J Orthop Res 31:792–799

Li JP, Habibovic P, van den Doel M, Wilson CE, de Wijn JR, van Blitterswijk CA, de Groot K (2007) Bone ingrowth in porous titanium implants produced by 3D fiber deposition. Biomaterials 28:2810–2820

Cheng A, Humayun A, Cohen DJ, Boyan BD, Schwartz Z (2014) Additively manufactured 3D porous Ti–6Al–4V constructs mimic trabecular bone structure and regulate osteoblast proliferation, differentiation and local factor production in a porosity and surface roughness dependent manner. Biofabrication 6:045007

Olivares-Navarrete R, Hyzy SL, Gittens RA, Schneider JM, Haithcock DA, Ullrich PF, Slosar PJ, Schwartz Z, Boyan BD (2013) Rough titanium alloys regulate osteoblast production of angiogenic factors. Spine J 13:1563–1570

Gittens RA, Olivares-Navarrete R, McLachlan T, Cai Y, Hyzy SL, Schneider JM, Schwartz Z, Sandhage KH, Boyan BD (2012) Differential responses of osteoblast lineage cells to nanotopographically-modified, microroughened titanium–aluminum–vanadium alloy surfaces. Biomaterials 33:8986–8994

Gittens RA, McLachlan T, Olivares-Navarrete R, Cai Y, Berner S, Tannenbaum R, Schwartz Z, Sandhage KH, Boyan BD (2011) The effects of combined micron-/submicron-scale surface roughness and nanoscale features on cell proliferation and differentiation. Biomaterials 32:3395–3403

Zinger O, Zhao G, Schwartz Z, Simpson J, Wieland M, Landolt D, Boyan B (2005) Differential regulation of osteoblasts by substrate microstructural features. Biomaterials 26:1837–1847

Steigenga JT, Al-Shammari KF, Nociti FH, Misch CE, Wang H-L (2003) Dental implant design and its relationship to long-term implant success. Implant Dent 12:306–317

Olivares-Navarrete R, Hyzy S, Berg M, Schneider J, Hotchkiss K, Schwartz Z, Boyan B (2014) Osteoblast lineage cells can discriminate microscale topographic features on titanium–aluminum–vanadium surfaces. Ann Biomed Eng 42:2551–2561

Pittenger MF, Mackay AM, Beck SC, Jaiswal RK, Douglas R, Mosca JD, Moorman MA, Simonetti DW, Craig S, Marshak DR (1999) Multilineage potential of adult human mesenchymal stem cells. Science 284:143–147

Fischer S, Schulte M, Hirsch T, Lehnhardt M, Behr B (2013) Mesenchymal stem cells in bone regeneration. In: Hayat MA (ed) Stem cells and cancer stem cells, vol 10. Springer, Dordrecht, pp 3–11

Marsell R, Einhorn TA (2011) The biology of fracture healing. Injury 42:551–555

Boyan BD, Hummert TW, Dean DD, Schwartz Z (1996) Role of material surfaces in regulating bone and cartilage cell response. Biomaterials 17:137–146

Gittens RA, Olivares-Navarrete R, Cheng A, Anderson DM, McLachlan T, Stephan I, Geis-Gerstorfer J, Sandhage KH, Fedorov AG, Rupp F, Boyan BD, Tannenbaum R, Schwartz Z (2013) The roles of titanium surface micro/nanotopography and wettability on the differential response of human osteoblast lineage cells. Acta Biomater 9:6268–6277

Olivares-Navarrete R, Raines AL, Hyzy SL, Park JH, Hutton DL, Cochran DL, Boyan BD, Schwartz Z (2012) Osteoblast maturation and new bone formation in response to titanium implant surface features are reduced with age. J Bone Miner Res 27:1773–1783

Olivares-Navarrete R, Hyzy SL, Park JH, Dunn GR, Haithcock DA, Wasilewski CE, Boyan BD, Schwartz Z (2011) Mediation of osteogenic differentiation of human mesenchymal stem cells on titanium surfaces by a Wnt-integrin feedback loop. Biomaterials 32:6399–6411

Yang J, Wang J, Yuan T, Zhu XD, Xiang Z, Fan YJ, Zhang XD (2013) The enhanced effect of surface microstructured porous titanium on adhesion and osteoblastic differentiation of mesenchymal stem cells. J Mater Sci Mater Med 24:2235–2246

Lv J, Jia Z, Li J, Wang Y, Yang J, Xiu P, Zhang K, Cai H, Liu Z (2015) Electron beam melting fabrication of porous Ti6Al4V scaffolds: cytocompatibility and osteogenesis. Adv Eng Mater 17:1391–1398

Amin Yavari S, van der Stok J, Chai YC, Wauthle R, Tahmasebi Birgani Z, Habibovic P, Mulier M, Schrooten J, Weinans H, Zadpoor AA (2014) Bone regeneration performance of surface-treated porous titanium. Biomaterials 35:6172–6181

Cheng A, Humayun A, Boyan BD, Schwartz Z (2016) Enhanced osteoblast response to porosity and resolution of additively manufactured Ti–6Al–4V constructs with trabeculae-inspired porosity. 3D Print Addit Manuf 3:10–21

Hyzy SL, Cheng A, Cohen DJ, Yatzkaier G, Whitehead AJ, Clohessy RM, Gittens RA, Boyan BD, Schwartz Z (2016) Novel hydrophilic nanostructured microtexture on direct metal laser sintered Ti–6Al–4V surfaces enhances osteoblast response in vitro and osseointegration in a rabbit model. J Biomed Mater Res A 104:2086–2098

Chen J, Dosier CR, Park JH, De S, Guldberg RE, Boyan BD, Schwartz Z (2016) Mineralization of three-dimensional osteoblast cultures is enhanced by the interaction of 1α,25-dihydroxyvitamin D3 and BMP2 via two specific vitamin D receptors. J Tissue Eng Regen Med 10:40–51

Dosier CR, Erdman CP, Park JH, Schwartz Z, Boyan BD, Guldberg RE (2012) Resveratrol effect on osteogenic differentiation of rat and human adipose derived stem cells in a 3-D culture environment. J Mech Behav Biomed Mater 11:112–122

Raines AL, Sunwoo M, Gertzman AA, Thacker K, Guldberg RE, Schwartz Z, Boyan BD (2011) Hyaluronic acid stimulates neovascularization during the regeneration of bone marrow after ablation. J Biomed Mater Res A 96:575–583

Zhao G, Raines AL, Wieland M, Schwartz Z, Boyan BD (2007) Requirement for both micron- and submicron scale structure for synergistic responses of osteoblasts to substrate surface energy and topography. Biomaterials 28:2821–2829

Schwartz Z, Raz P, Zhao G, Barak Y, Tauber M, Yao H, Boyan BD (2008) Effect of micrometer-scale roughness of the surface of Ti6Al4V pedicle screws in vitro and in vivo. J Bone Joint Surg Am 90:2485–2498

Boyan Barbara D, Lohmann Christoph H, Dean David D, Sylvia Victor L, Cochran David L, Schwartz Z (2001) Mechanisms involved in osteoblast response to implant surface morphology. Annu Rev Mater Res 31:357–371

Lian JB, Stein GS (1992) Concepts of osteoblast growth and differentiation: basis for modulation of bone cell development and tissue formation. Crit Rev Oral Biol Med 3:269–305

Beresford JN, Gallagher JA, Russell RG (1986) 1,25-Dihydroxyvitamin D3 and human bone-derived cells in vitro: effects on alkaline phosphatase, type I collagen and proliferation. Endocrinology 119:1776–1785

Wang X, Schwartz Z, Gittens RA, Cheng A, Olivares-Navarrete R, Chen H, Boyan BD (2015) Role of integrin α2β1 in mediating osteoblastic differentiation on three-dimensional titanium scaffolds with submicron-scale texture. J Biomed Mater Res A 103:1907–1918

Yang HJ, Kim KJ, Kim MK, Lee SJ, Ryu YH, Seo BF, Oh DY, Ahn ST, Lee HY, Rhie JW (2014) The stem cell potential and multipotency of human adipose tissue-derived stem cells vary by cell donor and are different from those of other types of stem cells. Cells Tissues Organs 199:373–383

Siddappa R, Licht R, van Blitterswijk C, de Boer J (2007) Donor variation and loss of multipotency during in vitro expansion of human mesenchymal stem cells for bone tissue engineering. J Orthop Res 25:1029–1041

Gittens RA, Olivares-Navarrete R, Schwartz Z, Boyan BD (2014) Implant osseointegration and the role of microroughness and nanostructures: lessons for spine implants. Acta Biomater 10:3363–3371

Bonewald LF, Harris SE, Rosser J, Dallas MR, Dallas SL, Camacho NP, Boyan B, Boskey A (2003) Von Kossa staining alone is not sufficient to confirm that mineralization in vitro represents bone formation. Calcif Tissue Int 72:537–547

Boyan BD, Bonewald LF, Paschalis EP, Lohmann CH, Rosser J, Cochran DL, Dean DD, Schwartz Z, Boskey AL (2002) Osteoblast-mediated mineral deposition in culture is dependent on surface microtopography. Calcif Tissue Int 71:519–529

Wuthier RE, Gore ST (1977) Partition of inorganic ions and phospholipids in isolated cell, membrane and matrix vesicle fractions: evidence for Ca-Pi-acidic phospholipid complexes. Calcif Tissue Res 24:163–171

McLean FM, Keller PJ, Genge BR, Walters SA, Wuthier RE (1987) Disposition of preformed mineral in matrix vesicles. Internal localization and association with alkaline phosphatase. J Biol Chem 262:10481–10488

Boskey AL, Bullough PG, Vigorita V, Di Carlo E (1988) Calcium-acidic phospholipid-phosphate complexes in human hydroxyapatite-containing pathologic deposits. Am J Pathol 133:22–29

Shah FA, Snis A, Matic A, Thomsen P, Palmquist A (2016) 3D printed Ti6Al4V implant surface promotes bone maturation and retains a higher density of less aged osteocytes at the bone-implant interface. Acta Biomater 30:357–367

Wennerberg A, Svanborg L, Berner S, Andersson M (2012) Spontaneously formed nanostructures on titanium surfaces. Clin Oral Implants Res 24:203–209

Wang XJ, Li YC, Lin JG, Hodgson PD, Wen CE (2008) Apatite-inducing ability of titanium oxide layer on titanium surface: the effect of surface energy. J Mater Res 23:1682–1688

Kokubo T, Miyaji F, Kim H-M, Nakamura T (1996) Spontaneous formation of bonelike apatite layer on chemically treated titanium metals. J Am Ceram Soc 79:1127–1129

Jonášová L, Müller FA, Helebrant A, Strnad J, Greil P (2004) Biomimetic apatite formation on chemically treated titanium. Biomaterials 25:1187–1194

Berglundh T, Abrahamsson I, Lang NP, Lindhe J (2003) De novo alveolar bone formation adjacent to endosseous implants. Clin Oral Implants Res 14:251–262

Acknowledgments

The authors would like to thank Aiza Humayan for assistance with cell culture. AB Dental (Ashdod, Israel) generously donated the implants and substrates used in this study. Research reported in this publication was supported by AB Dental and by the National Institute of Arthritis and Musculoskeletal and Skin Diseases of the National Institutes of Health under Award Number AR052102. The content is solely the responsibility of the authors and does not necessarily represent the official views of the National Institutes of Health.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

BDB is an paid consultant for Titan Spine LLC and an unpaid consultant for Institut Straumann AG. ZS is a paid consultant for AB Dental. AC and DJC declare that they have no conflict of interest.

Human and Animal Rights and Informed Consent

All animal procedures were performed in compliance with the 1991 Guiding Principles in the Care and Use of Animals, approved by the Council of the American Physiological Society. No human subjects used in this study.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Cheng, A., Cohen, D.J., Boyan, B.D. et al. Laser-Sintered Constructs with Bio-inspired Porosity and Surface Micro/Nano-Roughness Enhance Mesenchymal Stem Cell Differentiation and Matrix Mineralization In Vitro. Calcif Tissue Int 99, 625–637 (2016). https://doi.org/10.1007/s00223-016-0184-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00223-016-0184-9