Abstract

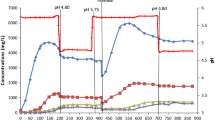

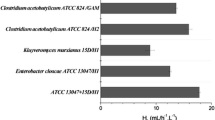

Fermentation with acetogens can be affected by cultivation gas phase, but to date, there is not enough evidence on that matter for Clostridium thermocellum and Moorella thermoacetica. In this work, the effects of sparged CO2 as well as sparged and non-sparged N2 on these microorganisms were studied using glucose and cellobiose as substrates. It was revealed that sparged CO2 and non-sparged N2 supported growth and acetic acid production by C. thermocellum and M. thermoacetica, while sparged N2 inhibited both of the microorganisms. Notably, part of the sparged CO2 was fermented by the co-culture system and contributed to an overestimation of the products from the actual substrate as well as an erring material balance. The best condition for the co-culture was concluded to be N2 without sparging. These results demonstrate the importance of cultivation conditions for efficient fermentation by anaerobic clostridia species.

Similar content being viewed by others

References

Agreda VH, Zoeller JR (1993) Acetic acid and its derivatives. Library of Congress, New York

Bothun GD, Knutson BL, Berberich JA, Strobel HJ, Nokes SE (2004) Metabolic selectivity and growth of Clostridium thermocellum in continuous culture under elevated hydrostatic pressure. Appl Microbiol Biotechnol 65:149–157. doi:10.1007/s00253-004-1554-1

Carere CR, Rydzak T, Cicek N, Levin DB, Sparling R (2014) Role of transcription and enzyme activities in redistribution of carbon and electron flux in response to N2 and H2 sparging of open-batch cultures of Clostridium thermocellum ATCC 27405. Appl Microbiol Biotechnol 98:2829–2840. doi:10.1007/s00253-013-5500-y

Drake HL, Gößner AS, Daniel SL (2008) Old acetogens, new light. Ann N Y Acad Sci 1125:100–128. doi:10.1196/annals.1419.016

Fontaine FE, Peterson WH, McCoy E, Johnson MJ, Ritter GJ (1942) A new type of glucose fermentation by Clostridium thermoaceticum. J Bacteriol 43:701–715

Hu P, Rismani-Yazdi H, Stephanopoulos G (2013) Anaerobic CO2 fixation by the acetogenic bacterium Moorella thermoacetica. AICHE J 59:3176–3183. doi:10.1002/aic.14127

Islam R, Cicek N, Sparling R, Levin D (2006) Effect of substrate loading on hydrogen production during anaerobic fermentation by Clostridium thermocellum 27405. Appl Microbiol Biotechnol 72:576–583. doi:10.1007/s00253-006-0316-7

Ito Y, Kawamoto H, Saka S (2016) Efficient and selective hydrogenation of aqueous acetic acid on Ru–Sn/TiO2 for bioethanol production from lignocellulosics. Fuel 178:118–123. doi:10.1016/j.fuel.2016.03.043

Johnson E, Reese E, Demain A (1982a) Inhibition of Clostridium thermocellum cellulase by end products of celluloysis. J Appl Biochem 4:64–71

Johnson EA, Sakajoh M, Halliwell G, Madia A, Demain AL (1982b) Saccharification of complex cellulosic substrates by the cellulase system from Clostridium thermocellum. Appl Environ Microbiol 43:1125–1132

Lamed RJ, Lobos JH, Su TM (1988) Effects of stirring and hydrogen on fermentation products of Clostridium thermocellum. Appl Environ Microbiol 54:1216–1221

Ljungdahl L, Irion E, Wood HG (1965) Total synthesis of acetate from CO2. I. Co-methylcobyric acid and co-(methyl)-5-methoxybenzimidazolylcobamide as intermediates with Clostridium thermoaceticum. Biochemistry 4:2771–2780. doi:10.1021/bi00888a030

Ljungdahl LG (1986) The autotrophic pathway of acetate synthesis in acetogenic bacteria. Annu Rev Microbiol 40:415–450. doi:10.1146/annurev.mi.40.100186.002215

Ljungdahl LG, Carreira LH, Garrison RJ, Rabek NE, Wiegel L (1985) Comparison of three thermophilic acetogenic bacteria for the production of calcium-magnesium acetate. Biotechnol Bioeng Symp Ser 15:207–223

Morag E, Bayer EA, Lamed R (1990) Relationship of cellulosomal and noncellulosomal xylanases of Clostridium thermocellum to cellulose-degrading enzymes. J Bacteriol 172:6098–6105

Nakamura Y, Miyafuji H, Kawamoto H, Saka S (2011) Acetic acid fermentability with Clostridium thermoaceticum and Clostridium thermocellum of standard compounds found in beech wood as produced in hot-compressed water. J Wood Sci 57:331–337. doi:10.1007/s10086-010-1169-3

Nomura Y, Iwahara M, Hongo M (1994) Production of acetic acid by Clostridium thermoaceticum in electrodialysis culture using a fermenter equipped with an electrodialyser. World J Microbiol Biotechnol 10:427–432. doi:10.1007/bf00144466

Parekh S, Cheryan M (1990) Fed-batch fermentation of glucose to acetate by an improved strain of Clostridium thermoaceticum. Biotechnol Lett 12:861–864. doi:10.1007/bf01022611

Rabemanolontsoa H, Kuninori Y, Saka S (2016) High conversion efficiency of Japanese cedar hydrolyzates into acetic acid by co-culture of Clostridium thermoaceticum and Clostridium thermocellum. J Chem Technol Biotechnol 91:1040–1047. doi:10.1002/jctb.4679

Saka S, Kawamoto H, Miyato H, Yamauchi K, Masuda S, Nakamura Y, Natthanon P, Sera Y, Tomiyama S, Nakamori K (2010) Method for producing alcohol by organic acid fermentation and direct hydrogenolysis. Japan Patent 2010239913, 28 Oct 2010

Saka S, Miyafuji H, Kohara Y, Kawamoto H (2013) Method for producing acetic acid using anaerobic microorganism and method for producing bioethanol. US Patent 8409832, 2 April 2013

Savage MD, Wu ZG, Daniel SL, Lundie LL, Drake HL (1987) Carbon monoxide-dependent chemolithotrophic growth of Clostridium thermoautotrophicum. Appl Environ Microbiol 53:1902–1906

Schulman M, Ghambeer RK, Ljungdahl LG, Wood HG (1973) Total synthesis of acetate from CO2: VII. Evidence with Clostridium thermoaceticum that the carboxyl of acetate is derived from the carboxyl of pyruvate by transcarboxylation and not by CO2 fixation. J Biol Chem 248:6255–6261

Schwarz W (2001) The cellulosome and cellulose degradation by anaerobic bacteria. Appl Microbiol Biotechnol 56:634–649. doi:10.1007/s002530100710

Vieira WB, Moreira LRDS, Neto AM, Ferreira EX (2007) Production and characterization of an enzyme complex from a new strain of Clostridium thermocellum with emphasis on its xylanase activity. Braz J Microbiol 38:237–242. doi:10.1590/S1517-83822007000200009

Wang G, Wang DIC (1984) Elucidation of growth inhibition and acetic acid production by Clostridium thermoaceticum. Appl Environ Microbiol 47:294–298

Weimer PJ, Weston WM (1985) Relationship between the fine structure of native cellulose and cellulose degradability by the cellulase complexes of Trichoderma reesei and Clostridium thermocellum. Biotechnol Bioeng 27:1540–1547. doi:10.1002/bit.260271104

Weimer PJ, Zeikus JG (1977) Fermentation of cellulose and cellobiose by Clostridium thermocellum in the absence of Methanobacterium thermoautotrophicum. Appl Environ Microbiol 33:289–297

Witjitra K, Shah MM, Cheryan M (1996) Effect of nutrient sources on growth and acetate production by Clostridium thermoaceticum. Enzyme Microb Tech 19:322–327. doi:10.1016/S0141-0229(96)00030-0

Xiong W, Lin PP, Magnusson L, Warner L, Liao JC, Maness P-C, Chou KJ (2016) CO2-fixing one-carbon metabolism in a cellulose-degrading bacterium Clostridium thermocellum. Proc Natl Acad Sci 113:13180–13185. doi:10.1073/pnas.1605482113

Xue J, Isern NG, Ewing RJ, Liyu AV, Sears JA, Knapp H, Iversen J, Sisk DR, Ahring BK, Majors PD (2014) New generation NMR bioreactor coupled with high-resolution NMR spectroscopy leads to novel discoveries in Moorella thermoacetica metabolic profiles. Appl Microbiol Biotechnol 98:8367–8375. doi:10.1007/s00253-014-5847-8

Acknowledgments

This work was supported by the Japan Science and Technology Agency (JST) under the Advanced Low Carbon Technology Research and Development Program (ALCA), for which the authors are extremely grateful.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Rabemanolontsoa, H., Van Nguyen, D., Jusakulvjit, P. et al. Effects of gas condition on acetic acid fermentation by Clostridium thermocellum and Moorella thermoacetica (C. thermoaceticum). Appl Microbiol Biotechnol 101, 6841–6847 (2017). https://doi.org/10.1007/s00253-017-8376-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-017-8376-4