Abstract

Screening for cellulase-producing microorganisms is routinely done on carboxymethylcellulose (CMC) plates. The culture plates are flooded either with 1% hexadecyltrimethyl ammonium bromide or with 0.1% Congo red followed by 1 M NaCl. In both cases, it takes a minimum of 30 to 40 minutes to obtain the zone of hydrolysis after flooding, and the hydrolyzed area is not sharply discernible. An improved method is reported herein for the detection of extracellular cellulase production by microorganisms by way of plate assay. In this method, CMC plates were flooded with Gram’s iodine instead of the reagents just mentioned. Gram’s iodine formed a bluish-black complex with cellulose but not with hydrolyzed cellulose, giving a sharp and distinct zone around the cellulase-producing microbial colonies within 3 to 5 minutes. The new method is rapid and efficient; therefore, it can be easily performed for screening large numbers of microbial cultures of both bacteria and fungi. This is the first report on the use of Gram’s iodine for the detection of cellulase production by microorganisms using plate assay.

Similar content being viewed by others

Introduction

The term “cellulases” refers to a group of enzymes that catalyze the hydrolysis of cellulose into sugars. Cellulolytic microorganisms play an important role in the biosphere by recycling cellulose, the most abundant carbohydrate produced by plants [1]. Cellulolytic enzymes from microorganisms also have many potential biotechnologic and industrial applications. Cellulases are required in large quantities because of their application in many industries, such as textiles, detergent, food, animal feed, bio-fuel, paper and pulp, pharmaceutical, and waste management [2–5, 8, 11, 12]. The first step in the development of an industrial process for the production of an enzyme is to isolate the potential strains. Isolation and screening of microbes for cellulases is of immense importance keeping in view the demand for new enzymes and the improvement of their biotechnologic applications. An easy, fast, and environmentally friendly qualitative method is described for screening microorganisms producing extracellular cellulase on agar plate.

Material and Methods

Soil Samples and Microorganisms

Soil samples were collected from different locations of western Himalaya (Himachal Pradesh, India) for the isolation of bacteria-producing cellulases. Samples were transported to the laboratory and stored at 4ºC until used. Ten-fold serial dilutions of each soil sample were prepared in sterilized distilled water, and 0.1 ml diluted sample was spread on the surface of nutrient agar medium (0.3% beef extract, 0.5% peptone, 0.5 % NaCl, and 1.7% agar [pH 7.0]) for bacteria; potato dextrose agar (20% potatoes, 2% dextrose,1.7% agar) (HiMedia, India) was used for fungi. Plates were incubated at 28°C for 48 hours for bacteria and 96 hours for fungi. Morphologically different colonies appearing on the plates were purified on the respective medium for bacteria and fungi. The purified isolates were preserved at 4ºC and used during the course of study. The actinomycete Streptomyces sannanensis MTCC 6637 was obtained from the Microbial Type Culture Collection & Gene Bank, Institute of Microbial Technology, India.

Screening and Identification of Cellulase Producers

Five microlitres of overnight grown culture was spot plated on CMC agar (0.2% NaNO3, 0.1% K2HPO4, 0.05% MgSO4, 0.05% KCl, 0.2% carboxymethylcellulose (CMC) sodium salt, 0.02% peptone, and 1.7% agar) (HiMedia, India). Plates incubated at 28ºC for 48 hours were flooded with 1% hexadecyltrimethyl ammonium bromide (HAB) for 30 to 40 minutes [6]. From cellulase-producing microorganisms, two potential bacterial strains RK3 (Gram +ve) and MN34 (Gram –ve) and one fungal strain RS2 were selected for identification and further studies. Genomic DNA from bacterial strains was isolated and amplified by using universal 16S rRNA primers [9], and fungal DNA was isolated and amplified by using internal transcribed spacer 1 (ITS 1) and internal transcribed spacer 4 (ITS 4) primers [15]. The amplified gene products were purified from agarose gel using Qiaquick Gel Extraction Kit (Qiagen, Germany). Nucleotide sequencing of the genes was done by using Big Dye Terminator Cycle Sequencing Kit (Applied Biosystems) and 3130xl Genetic Analyzer (Applied Biosystems). The BLASTN program (http://www.ncbi.nlm.nih.gov/BLAST/; National Center for Biotechnology Information, Bethesda, MD) was used for homology searches with the standard program default.

Comparison of Cellulase Screening Methods

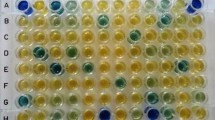

Screening of cellulase producers was done on CMC agar and CMC Congo red agar (0.05% K2HPO4, 0.025% MgSO4, 0.188% CMC sodium salt, 0.02% Congo red, 1.5% agar, 0.2% gelatin, and 10% soil extract). Five microlitres of cellulase-producing bacteria were spot plated on CMC agar in three sets and on CMC Congo red agar. The plates were incubated at 28 °C for 48 hours. The first set of plates was flooded with 1% HAB for 30 to 40 minutes [6]; the second set of plates was flooded with 0.1% Congo red for 15 to 20 minutes and then with 1 M NaCl for 15 to 20 minutes [14]; and the third set of plates was flooded with Gram’s iodine (2.0 g KI and 1.0 g iodine in 300 ml distilled water) for 3 to 5 minutes (new method). After incubation, CMC Congo red plates were also observed for zone of clearance around the colony [7]. In another set of experiments, the standard cellulase from Aspergillus niger was used (Sigma-Aldrich) for validation of results. Ten microlitres of enzyme solution (10 mg/mL) was poured into the wells in CMC plates, which were made with a gel cutter, and the plates were incubated for 24 hours at 28ºC and flooded individually with 1% HAB for 30 to 40 minutes, 0.1% Congo red for 15 to 20 minutes, followed by 1 M NaCl for 15 to 20 minutes, and Gram’s iodine for 3 to 5 minutes.

Results and Discussion

The two bacterial isolates producing cellulase were identified as Bacillus sp. RK3 (AM943531) and Pseudomonas sp. MN34 (AM992885) based on partial 16S rRNA gene sequencing. The cellulase-producing fungal-isolate strain RS2 was identified as Penicillium chrysogenum RS2 (AM948960) by sequencing of its ITS1–5.8S–ITS2 region [15]. These three cultures and one actinomycete S. sannanensis MTCC 6637 were used for further studies. The observation on the development of cellulose clearance zone showed Gram’s iodine to be more effective compared with HAB, and Congo red plus 1 M NaCl for screening and qualitative estimation of cellulase production by microorganisms on CMC agar plates. The plates flooded with HAB or with Congo red plus 1 M NaCl as well as the CMC Congo red plates showed low intensity of clearance zone (Figs. 1 and 2). There was difficulty in differentiating the enzyme-lysed zone from the CMC-containing area in the plates flooded with these reagents. Moreover, there was a waiting period of at least 30 to 40 minutes for the development of clearance zones [6, 14]. Interestingly, the plates flooded with Gram’s iodine showed distinct, clear, and prominent zones of clearance around the colonies showing cellulase production with bluish-black colouration in the nonhydrolysed part of the medium (Fig. 3). It took only 3 to 5 minutes for the development of clearance zones after flooding. The plates with Congo red added to the medium before inoculation also showed low intensity for zone of clearance (Fig. 4). Moreover, Congo red (“Direct Red 28” CI 22120, empiric formula C32H22N6O6S2Na2) is a benzidine-based dye and expected to metabolize to benzidine, which is a known carcinogen [10, 13]. There is a possibility that the added Congo red could have affected growth and cellulase production by the isolates because of its harmful effects. However, a sharp increase in the colour contrast of the hydrolyzed zone and nonhydrolysed portion of the medium is obtained on flooding with Gram’s iodine because it further enhanced the appearance of already sharply discernible clearance zone by producing bluish-black complex with cellulose (polysaccharide) and not with the glucose (monosaccharide). This new method for assaying has the double advantage of being quick as well as based on nontoxic chemicals.

Furthermore, the method was also validated by using the standard cellulase form A. niger (Fig. 5). It was observed that plates flooded with Gram’ iodine after incubation also showed distinct, clear, and prominent zone in 3 to 5 minutes, whereas the plates flooded with HAB or with Congo red plus 1 M NaCl showed hazy zones after 30 to 40 minutes of incubation. The new method worked well with bacteria, actinomycetes, and fungi; hence, it can be employed for screening a large number of microorganisms with greater throughput.

Conclusion

The present studies showed that the use of Gram’s iodine remarkably enhances the sharpness of the clearance zone, making the process for screening cellulase-producing microorganisms easy, efficient, and rapid. Although the new method is a qualitative assay, the greatest advantage lies in its simplicity, quickness of performance, and effectiveness for screening a large number of microorganisms. Moreover, it avoids the use of toxic chemicals.

References

Beguin P, Anbert JP (1993) The biological degradation of cellulose. FEMS Microbiol Rev 13:25–58

Bhat MK (2000) Cellulases and related enzymes in biotechnology. Biotechnol Adv 18:355–383

Camassola M, Dillon AJP (2007) Production of cellulases and hemicellulases by Penicillium echinulatum grown on pretreated sugar cane bagasse and wheat bran in solid-state fermentation. J Appl Microbiol 103:2196–2204

Coughlan MP (1985) The production of fungal and bacterial cellulases with comment on their production and application. Biotechnol Genet Eng Rev 13:39–109

Gusakov AV, Berlin AG, Popova NN, Okunev ON, Sinitsyn AO, Sinitsyn AP (2000) A comparative study of different cellulase preparations in the enzymatic treatment of cotton fabrics. Appl Biochem Biotechnol 88:119–126

Hankin L, Anagnostakis S (1977) Solid media containing carboxy methyl cellulose to detect CM cellulase activity of microorganisms. J Gen Microbiol 98:109–115

Hendricks CW, Doyle JD, Hugley B (1995) A new solid medium for enumerating cellulose-utilizing bacteria in soil. Appl Environ Microbiol 61:2016–2019

Ito S (1997) Alkaline cellulases from alkaliphilic Bacillus: Enzymatic properties, genetics and application to detergents. Extremophiles 1:61–66

Kasana RC, Sharma UK, Sharma N, Sinha AK (2007) Isolation and identification of a novel strain of Pseudomonas chlororaphis capable of transforming isoeugenol to vanillin. Curr Microbiol 54:457–461

Lamb J, Loy T (2005) Seeing red: The use of Congo Red dye to identify cooked and damaged starch grains in archaeological residues. J Archaeol Sci 32:1433–1440

Mandels M (1985) Applications of cellulases. Biochem Soc Trans 13:414–415

Park J, Park K (2001) Improvement of the physical properties of reprocessed paper by using biological treatment with modified cellulase. Bioresour Technol 79:91–94

Tanaka K, Mii T, Marui S, Matsubara I, Igaki H (1981) Mutagenicity of urinary metabolites of benzidine and benzidine-based azo dyes. Int Arch Occup Environ Health 49:177–185

Teather RM, Wood PJ (1982) Use of Congo red polysaccharide interactions complex formation between Congo red and polysaccharide in detection and assay of polysaccharide hydrolases. Methods Enzymol 160:59–74

White TJ, Bruns T, Lee S, Taylor J (1990) Amplification and direct sequencing of fungal ribosomal RNA genes for phylogenetics. In: Innis MA, Gelfand DH, Sninsky JJ, White TJ (eds) PCR protocols: a guide to methods and applications. Academic, New York, NY, pp 315–322

Acknowledgments

The authors are grateful to P. S. Ahuja, Director, Institute of Himalayan Bioresource Technology (CSIR), Palampur, India, for providing the necessary laboratory facility. The Council of Scientific and Industrial Research (CSIR) is also acknowledged for providing financial support under the project NWP06. This is IHBT communication No. 0839.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kasana, R.C., Salwan, R., Dhar, H. et al. A Rapid and Easy Method for the Detection of Microbial Cellulases on Agar Plates Using Gram’s Iodine. Curr Microbiol 57, 503–507 (2008). https://doi.org/10.1007/s00284-008-9276-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-008-9276-8