Abstract

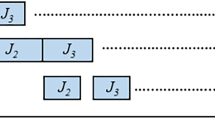

This paper addresses the simultaneous lot-sizing and scheduling of several products in multi-stage flow line production systems consisting of heterogeneous parallel production lines per stage. The limited capacity of the production lines may be further reduced by sequence dependent setup times. Deterministic, dynamic demand of standard products has to be met without backlogging with the objective of minimizing sequence dependent setup, holding and production costs as well as costs for external purchase, overtime, and standby. Different mixed-integer programming (MIP) model formulations are proposed and tested using a standard MIP-solver. Furthermore, construction heuristics like LP-and-Fix and Relax-and-Fix are designed and applied. The solution quality and computational performance of these approaches are examined in several test scenarios.

Similar content being viewed by others

References

Araujo S, Arenales M, Clark A (2007) Joint rolling-horizon scheduling of materials processing and lot-sizing with sequence-dependent setups. J Heuristics 13(4): 337–358

Barany I, van Roy T, Wolsey L (1984) Strong formulations for multi-item capacitated lot sizing. Manag Sci 30(10): 1255–1261

Buschkühl L, Sahling F, Helber S, Tempelmeier H (2010) Dynamic capacitated lot-sizing problems: a classification and review of solution approaches. OR Spectrum 32: 231–261

Clark AJ, Scarf H (1960) Optimal policies for a multi-echelon inventory problem. Manag Sci 6: 475–490

Dauzère-Péres S, Lasserre J-B (1994) Integration of lotsizing and scheduling decisions in a job-shop. Eur J Oper Res 75: 413–426

Denizel M, Süral H (2006) On alternative mixed integer programming formulations and LP-based heuristics for lot-sizing with setup times. J Oper Res Soc 57: 389–399

Denizel M, Altekin F, Süral H, Stadtler H (2008) Equivalence of the LP relaxations of two strong formulations for the capacitated lot-sizing problem with setup times. OR Spectrum 30: 773–785

Drexl A, Haase K (1995) Proportional lotsizing and scheduling. Int J Prod Econ 40: 73–87

Drexl A, Kimms A (1997) Lot sizing and scheduling—survey and extensions. Eur J Oper Res 99(2): 221–235

Eppen G, Martin R (1987) Solving multi-item capacitated lot-sizing problems using variable redefinition. Oper Res 35(6): 832–848

Fandel G, Stammen-Hegener C (2006) Simultaneous lot sizing and scheduling for multi-product multi-level production. Int J Prod Econ 104: 308–316

Ferreira D, Morabito R, Rangel S (2009) Solution approaches for the soft drink integrated production lot sizing and scheduling problem. Eur J Oper Res 196(2): 697–706

Fleischmann B (1990) The discrete lot-sizing and scheduling problem. Eur J Oper Res 44: 337–348

Fleischmann B, Meyr H (1997) The general lotsizing and scheduling problem. OR Spectrum 19(1): 11–21

Grünert T (1998) Multi-level sequence-dependent dynamic lotsizing and scheduling. Shaker Verlag, Aachen

Haase K (1994) Lotsizing and scheduling for production planning. Springer, Berlin

Haase K (1996) Capacitated lot-sizing with sequence dependent setup costs. OR Spectrum 18: 51–59

Jans R, Degraeve Z (2007) Meta-heuristics for dynamic lot sizing: A review and comparison of solution approaches. Eur J Oper Res 177: 1855–1875

Kallrath J (1999) The concept of contiguity in models based on time-indexed formulations. In: Keil F, Mackens W, Voß H, Werther J (eds) Scientific computing in chemical engineering, II. Springer, Berlin, pp 330–337

Karimi B, Fatemi Ghomi S, Wilson J (2003) The capacitated lot sizing problem: a review of models and algorithms. Omega 31: 365–378

Karmarkar U, Schrage L (1985) The deterministic dynamic product cycling problem. Oper Res 33(2): 326–345

Kimms A (1996) Multi-level, single-machine lot sizing and scheduling (with initial inventory). Eur J Oper Res 89(1): 86–99

Krarup J, Bilde O (1977) Plant location set covering and economic lot sizing: An o(mn) algorithm for structured problems. In: Collatz L (eds) Numerische Methoden bei Optimierungsaufgaben, Bd. 3, Optimierung bei graphentheoretischen und ganzzahligen Problemen. Birkhäuser, Basel, pp 155–180

Lang JC (2009) Production and inventory management with flexible bills-of-materials and substitutions. Springer, Berlin

Meyr H (2000) Simultaneous lotsizing and scheduling by combining local search with dual reoptimization. Eur J Oper Res 120(2): 311–326

Meyr H (2002) Simultaneous lotsizing and scheduling on parallel machines. Eur J Oper Res 139: 277–292

Meyr H (2004) Simultane Losgröß en- und Reihenfolgeplanung bei mehrstufiger kontinuierlicher Fertigung. Zeitschrift für Betriebswirtschaft 74(6): 585–610

Mohammadi M, Fatemi Ghomi SMT, Karimi B, Torabi SA (2009) Development of heuristics for multi-product multi-level capacitated lotsizing problem with sequence-dependent setups. J Appl Sci 9(2): 296–303

Persson J, Göthe-Lundgren M, Lundgren J, Gendron B (2004) A tabu search heuristic for scheduling the production processes at an oil refinery. Int J Prod Res 42(3): 445–471

Pochet Y, Wolsey L (1994) Polyhedra for lot-sizing with Wagner–Whitin costs. Math Programm 67: 297–323

Pochet Y, Wolsey L (2006) Production planning by mixed integer programming. Springer series in operations research and financial engineering. Springer, New York

Quadt D, Kuhn H (2008) Capacitated lot-sizing with extensions: a review. 4OR: Q J Oper Res 6: 61–83

Rosling K (1986) Optimal lot-sizing for dynamic assembly systems. In: Axsäter S, Schneeweiß Ch, Silver E (eds) Multi-stage production planning and inventory control. Springer, Berlin, pp 119–131

Sahling F (2010) Mehrstufige Losgröß enplanung bei Kapazitätsrestriktionen. Gabler

Salomon M, Kroon L, Kuik R, van Wassenhove L (1991) Some extensions of the discrete lotsizing and scheduling problem. Manag Sci 37: 801–812

Sikora R, Chhajed D, Shaw M (1996) Integrating the lot-sizing and sequencing decisions for scheduling a capacitated flow line. Comput Ind Eng 30(4): 659–679

Stadtler H (1996) Mixed integer programming model formulations for dynamic multi-item multi-level capacitated lotsizing. Eur J Oper Res 94(3): 561–581

Stadtler H (2000) Improved rolling schedules for the dynamic single-level lot-sizing problem. Manag Sci 46(2): 318–326

Stadtler H (2011) Multi-level single machine lot-sizing and scheduling with zero lead times. Eur J Oper Res 209(3): 241–252

Stadtler H, Sahling F (2011) A lot-sizing and scheduling model for multi-stage flow lines with zero lead times. Technical report, Universität Hamburg, Institut für Logistik und Transport, Hamburg, Germany

Suerie C (2005a) Campaign planning in time-indexed model formulations. Int J Prod Res 43: 49–66

Suerie C (2005b) Time continuity in discrete time models: new approaches for production planning in process industries. Springer, Heidelberg

Suerie C (2006) Modeling of period overlapping setup times. Eur J Oper Res 174(2): 874–886

Suerie C, Stadtler H (2003) The capacitated lot-sizing problem with linked lot sizes. Manag Sci 49(8): 1039–1054

Toledo C, França P, Morabito R, Kimms A (2009) Multi-population genetic algorithm to solve the synchronized and integrated two-level lot sizing and scheduling problem. Int J Prod Res 47(11): 3097–3119

Transchel S, Minner S, Kallrath J, Löhndorf N, Eberhard U (2011) A hybrid general lot-sizing and scheduling formulation for a production process with a two-stage product structure. Int J Prod Res 49(9): 2463–2480

Zhu X, Wilhelm WE (2005) Scheduling and lot sizing with sequence-dependent setup: a literature review. IIE Trans 38(11): 987–1007

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Seeanner, F., Meyr, H. Multi-stage simultaneous lot-sizing and scheduling for flow line production. OR Spectrum 35, 33–73 (2013). https://doi.org/10.1007/s00291-012-0296-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00291-012-0296-1