Abstract

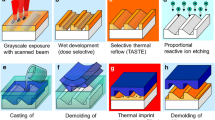

A new laser microstereophotolithography process has been developed in our laboratory to manufacture three-dimensional parts with a high accuracy. As usual in laser stereophotolithography or laser microstereophotolithography, the part is manufactured layer by layer by a light-induced space-resolved polymerization. Until now, in all the already existing microstereophotolithography devices a layer is manufactured vector by vector, by moving the part beneath the initiating light source which remains motionless. We developed a simpler and easier process, in which we can manufacture an entire layer by irradiating its whole surface only once: we used a liquid crystal display as a dynamic generator of masks. In the device we set up, we need only one mobile element, the z translator, all the others are fixed. We manufactured several different 3D microparts, in particular a piece of bevel microgearing with helicoidal cogs, the volume of which is less than half a cubic millimetre.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Received: 14 December 1995 / Accepted: 16 September 1996

Rights and permissions

About this article

Cite this article

Bertsch, A., Zissi, S., Jézéquel, J. et al. Microstereophotolithography using a liquid crystal display as dynamic mask-generator. Microsystem Technologies 3, 42–47 (1997). https://doi.org/10.1007/s005420050053

Issue Date:

DOI: https://doi.org/10.1007/s005420050053