Abstract

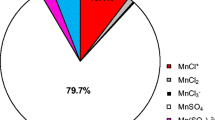

In this communication, we present a generalization of our investigations concerning current state in the development of trivalent chromium baths as an environmentally friendly alternative to hazardous electroplating baths containing extremely toxic hexavalent chromium compounds. The main technological properties of sulfate trivalent chromium baths containing carbamide and formic acid as organic additives are described and compared to those typical of common Cr(VI) plating bath. It is shown that thick nanocrystalline chromium–carbon deposits may be obtained from the Cr(III) electrolytes under study, with some physicochemical and service properties of such coatings exceeding those of “usual” chromium deposits. The proposed trivalent chromium baths are distinguished by their high current efficiency and electrodeposition rate. The covering power of the Cr(III) baths is poorer than in case of hexavalent chromium baths; it may be improved by applying basic chromium sulfate (chrome tanning agent) instead of chromium sulfate as a source of Cr(III) ions in solution. There is no need to utilize toxic lead anodes in Cr(III) deposition processes. It is noted that a grave shortcoming of trivalent baths is their low conductivity in comparison with the hexavalent ones.

Similar content being viewed by others

Notes

When cathodic current density exceeds indicated values, the surface appearance of deposits becomes worse—the coating’s surface is rough and the “burning” occurs on the deposits’ surface.

“BS” trivalent chromium bath was used in these experiments.

References

Baral A, Engelken R (2005) Modeling, optimization, and comparative analysis of trivalent chromium electrodeposition from aqueous glycine and formic acid baths. J Electrochem Soc 152:C504–C512

Chien CW, Liu CL, Chen FJ, Lin KH, Lin CS (2012) Microstructure and properties of carbon–sulfur-containing chromium deposits electroplated in trivalent chromium baths with thiosalicylic acid. Electrochim Acta 72:74–80

Danilov FI, Velichenko AB (1993) Electrocatalytic activity of anodes in reference to Cr(III) oxidation reaction. Electrochim Acta 38:437–440

Danilov FI, Protsenko VS, Gordiienko VO, Kwon SC, Lee JY, Kim M (2011) Nanocrystalline hard chromium electrodeposition from trivalent chromium bath containing carbamide and formic acid: structure, composition, electrochemical corrosion behavior, hardness and wear characteristics of deposits. Appl Surf Sci 257:8048–8053

Danilov FI, Protsenko VS, Gordiienko VO (2013a) Electrode processes occurring during the electrodeposition of chromium–carbon coatings from solutions of Cr(III) salts with carbamide and formic acid additions. Russ J Electrochem 49:475–482

Danilov FI, Protsenko VS, Gordiienko VO, Baskevich AS, Artemchuk VV (2013b) Electroplating of wear-resistant nanocrystalline coatings from a bath containing basic chromium(III) sulfate (chrome tanning agent). Prot Met Phys Chem Surf 49:299–303

Dennis JK, Such TE (1986) Nickel and chromium plating. Butterworths, London

Dettmer A, Nunes KGP, Gutterres M, Marcilio NR (2010) Production of basic chromium sulfate by using recovered chromium from ashes of thermally treated leather. J Hazard Mater 176:710–714

Drela I, Szynkarczuk J, Kubicki J (1989) Electrodeposition of chromium from Cr(III) electrolytes in the presence of formic acid. J Appl Electrochem 19:933–936

Edigaryan AA, Safonov VA, Lubnin EN, Vykhodtseva LN, Chusova GE, Polukarov YuM (2002) Properties and preparation of amorphous chromium carbide electroplates. Electrochim Acta 47:2775–2786

Ghaziof S, Golozar MA, Raeissi K (2010a) Characterization of as-deposited and annealed Cr–C alloy coatings produced from a trivalent chromium bath. J Alloys Compd 496:164–168

Ghaziof S, Raeissi K, Golozar MA (2010b) Improving the corrosion performance of Cr–C amorphous coatings on steel substrate by modifying the steel surface preparation. Surf Coat Technol 205:2174–2183

Huang CA, Lieu UW, Chuang CH (2009a) Role of nickel undercoat and reduction-flame heating on the mechanical properties of Cr–C deposit electroplated from a trivalent chromium based bath. Surf Coat Technol 203:2921–2926

Huang CA, Liu YW, Chuang CH (2009b) The hardening mechanism of a chromium–carbon deposit electroplated from a trivalent chromium-based bath. Thin Solid Films 517:4902–4904

Huang CA, Liu YW, Yu C, Yang C-C (2011) Role of carbon in the chromium deposit electroplated from a trivalent chromium-based bath. Surf Coat Technol 205:3461–3466

Kasian O, Luk’yanenko T, Velichenko A (2012) Anodic decomposition of complexing agents in electrolytes based on Cr(III) salts at composite TiO x /PtO y electrodes. Chem Chem Technol 6:241–244

Kwon SC, Kim M, Park SU, Kim DY, Kim D, Nam KS, Choi Y (2004) Characterization of intermediate Cr–C layer fabricated by electrodeposition in hexavalent and trivalent chromium baths. Surf Coat Technol 183:151–156

Kwon S-C, Kim M, Lee J-Y, Lee S-Y, Kang D-G, Danilov FI, Protsenko VS, Gordiienko VO, Velichenko AB (2012) Trivalent chromium plating solution and plating method using the same. US Patent Application No. 2012/0024,714

Liang A, Ni L, Liu Q, Zhang J (2013) Structure characterization and tribological properties of thick chromium coating electrodeposited from a Cr(III) electrolyte. Surf Coat Technol 218:23–29

Phuong NV, Kwon SC, Lee JY, Lee JH, Lee KH (2012) The effects of pH and polyethylene glycol on the Cr(III) solution chemistry and electrodeposition of chromium. Surf Coat Technol 206:4349–4355

Protsenko V, Danilov F (2009) Kinetics and mechanism of chromium electrodeposition from formate and oxalate solutions of Cr(III) compounds. Electrochim Acta 54:5666–5672

Protsenko VS, Gordiienko VO, Danilov FI, Kwon SC (2011a) Thick chromium electrodeposition from trivalent chromium bath containing carbamide and formic acid: an investigation into current efficiency, electrodeposition rate and surface morphology. Met Finish 109(4–5):33–37

Protsenko VS, Danilov FI, Gordiienko VO, Kwon SC, Kim M, Lee JY (2011b) Electrodeposition of hard nanocrystalline chrome from aqueous sulfate trivalent chromium bath. Thin Solid Films 520:380–383

Protsenko VS, Danilov FI, Gordiienko VO, Baskevich AS, Artemchuk VV (2012a) Improving hardness and tribological characteristics of nanocrystalline Cr-C films obtained from Cr(III) plating bath using pulsed electrodeposition. Int J Refract Met Hard Mater 31:281–283

Protsenko VS, Gordiienko VO, Danilov FI (2012b) Unusual “chemical” mechanism of carbon co-deposition in Cr–C alloy electrodeposition process from trivalent chromium bath. Electrochem Commun 17:85–87

Schröder N, Sonntag B, Plieth W (2012) Deposition of amorphous chromium layers. J Solid State Electrochem 16:3551–3558

Song YB, Chin D-T (2002) Current efficiency and polarization behavior of trivalent chromium electrodeposition process. Electrochim Acta 48:349–356

Sugashini S, Begum KMMS (2013) Optimization using central composite design (CCD) for the biosorption of Cr(VI) ions by cross linked chitosan carbonized rice husk (CCACR). Clean Technol Environ Policy 15:293–302

Surviliene S, Nivinskiene O, Cesuniene A, Selskis A (2006) Effect of Cr(III) solution chemistry on electrodeposition of chromium. J Appl Electrochem 36:649–654

Sziraki L, Kuzmann E, Papp K, Chisholm CU, El-Sharif MR, Havancsak K (2012) Electrochemical behaviour of amorphous electrodeposited chromium coatings. Mater Chem Phys 133:1092–1100

Zeng Z, Wang L, Liang A, Zhang J (2006) Tribological and electrochemical behavior of thick Cr–C alloy coatings electrodeposited in trivalent chromium bath as an alternative to conventional Cr coatings. Electrochim Acta 52:1366–1373

Zeng Z, Sun Y, Zhang J (2009) The electrochemical reduction mechanism of trivalent chromium in the presence of formic acid. Electrochem Commun 11:331–334

Zeng Z, Zhang Y, Zhao W, Zhang J (2011) Role of complexing ligands in trivalent chromium electrodeposition. Surf Coat Technol 205:4771–4775

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Protsenko, V.S., Danilov, F.I. Chromium electroplating from trivalent chromium baths as an environmentally friendly alternative to hazardous hexavalent chromium baths: comparative study on advantages and disadvantages. Clean Techn Environ Policy 16, 1201–1206 (2014). https://doi.org/10.1007/s10098-014-0711-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-014-0711-1