Abstract

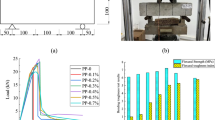

In order to optimise the construction of soft body armour panels by hybridization, this study aims to identify materials determination for hybrid panel. Different ballistic characteristics of aramid woven fabrics and Ultra High Molecular Weight Polyethylene uni-directional laminates were investigated through ballistic test and fractorgaphic analysis. With an increasing of total layer numbers in a panel, specific energy absorption of Twaron woven panel shows a decrease trend, and Dyneema UD panel exhibits an increasing trend. Such reverse trend of ballistic performance is due to different failure modes of two materials. According to fractorgraphic analysis, Twaron fabric has large transverse deformation for back layers in a perforated panel. This results in higher energy absorption in back layers. For Dyneema UD, thermal damage is the dominant failure mode, which can result in performance degradation especially for front layers on the strike face. In addition, Dyneema UD exhibits significant advantage of minimize Backface Signature (BFS) and a little higher perforation ratio than that of Twaron woven panels. Based on these findings, an optimized hybrid panel is designed by combing Twaron woven fabric before Dyneema UD. In comparison with other panels with different layer sequences, this hybridization manner exhibited better ballistic performance, including improvement of energy absorption, minimized BFS of the non-perforated panel and reduction of perforation ratio. These findings indicated that material determination for hybrid design should be based on ballistic characteristics of different materials and requirements of different regions in a panel.

Similar content being viewed by others

References

Languerand, D.L., et al.: Inelastic behavior and fracture of high modulus polymeric fiber bundles at high strain-rates. Mater. Sci. Eng. A. 500, 216–224 (2009)

Dingenen, J.L.J.V.: In: Hearle, J.W.S. (ed.) High-performance fibres, p. 337. Woodhead Publishing Limited, Cambridge (2001)

Lane, R.A.: Hign performance fibers for personnel and vehicle armor systems. The AMPTIAC Quarterly. 9, 3–9 (2005)

Chocron, S.: From fibers to composites, in conference at Airbus military. Southwest Research Institute, San Antonio (2009)

Prevorsek D.C., et al.: Ballistic armor material from spectra® fibre, in The 33rd International SAMPE Symposium (1988)

Hearle, J.W.S.: Atlas of fibre fracture and damage to textiles, p. 329. Woodhead publishing limited, Boca Raton Boston New York Washington (1998)

Azrin Hani, A.R., et al.: Body armor technology: a review of materials, construction techniques and enhancement of ballistic energy absorption. Adv. Mater. Res. 488-489, 806–812 (2012)

Chitrangad,: Hybrid ballistic fabric. 16 (1993)

Chitrangad and Midlothian V.: Hybrid ballistic fabric 1993, E. I. du Pont de Nemours and company, Wilmington, Del (1993)

Chitrangăd H., Structure B.: E. I. DuPont De Nemours and company, (1994)

Chabba S., Vanek D., Cordova D.: Multilayerd material sheet for use in soft ballistics. US (2010)

Karahan, M.: Comparison of ballistic performance and energy absorption capabilities of woven and unidirectional aramid fabrics. Text. Res. J. 78, 718–730 (2008)

Park, J.L., Chi, Y.-S., Kang, T.J.: Ballistic performance of hybrid panels composed of unidirectional/woven fabrics. Text. Res. J. 0(00), 1–16 (2012)

Kedzierski, P., et al.: Experimental study of hybrid soft ballistic structures. Compos. Struct. 153, 204–211 (2016)

AK Bandaru, L.V., Ahmad, S.: The effect of hybridization on the ballistic impact behavior of hybrid composite armors. Composites Part B. Eng. 76, 300–319 (2015)

Bandaru, A.K., et al.: Ballistic impact response of Kevlar (R) reinforced thermoplastic composite armors. Int. J. Impact Eng. 89, 1–13 (2016)

Xiaofei Liu, et al.: Ballistic performance of UHMWPE fabrics/EAMS hybrid panel. J. Mater. Sci (2018)

Yang, Y., Chen, X.: Investigation of energy absorption mechanisms in a soft armor panel under ballistic impact. Text. Res. J. 87(20), 2475–2486 (2016)

Yanfei, Y., Xiaogang, C.: Investigation of failure modes and influence on ballistic performance of ultra-high molecular weight polyethylene (UHMWPE) uni-directional laminate for hybrid design. Compos. Struct. 174, 233–243 (2017)

Jacobs, M.J.N., Van Dingenen, J.L.J.: Ballistic protection mechanisms in personal Armour. J. Mater. Sci. 36, 3137–3142 (2001)

U.S. Department of Justice O.o.J.P: National institute of justice, Ballistic resistance of body armor NIJ Standard-0101.06. National Institute of Justice, Washington (2008)

Cunniff, P.M.: An analysis of the system effects in woven fabrics under ballistic impact. Text. Res. J. 62(9), 495–509 (1992)

Shim, V.P.W., Tan, V.B.C., Tay, T.E.: Modelling deformation and damage characteristics of woven fabric under small projectile impact. Int. J. Impact. Eng. 16(4), 585–605 (1995)

Acknowledgements

This work is financially supported by project supported by National Science Foundation for Young Scientists of China (Grant No.11702337). We are grateful to Henan Collaborative Innovation Center of Textile and garment industry for their assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, Y., Chen, X. Determination of Materials for Hybrid Design of 3D Soft Body Armour Panels. Appl Compos Mater 25, 861–875 (2018). https://doi.org/10.1007/s10443-018-9716-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-018-9716-y