Abstract

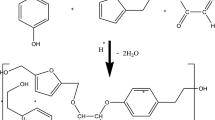

The use of renewable feedstocks in foam technology has created a worldwide demand for more sustainable materials. Castor oil is a vegetable oil, composed mainly of triricinoglycerol, a natural polyol, suitable for polyurethane foam production. In this study, castor oil and variable amounts of microcrystalline cellulose (MCC) fibers were used in a straightforward one-pot synthesis approach for the preparation of novel biofoams. The ensuing biofoams were characterized by several techniques, including attenuated total reflectance Fourier transform infrared spectroscopy, scanning electron microscopy and thermogravimetric analysis, and their mechanical performance was evaluated by compression mechanical testing and by dynamic mechanical thermal analysis. They were (semi-) flexible, with a cell-like morphology and reinforced toughness due to the use of MCC. They had a Young’s modulus varying between 0.188 and 1.06 MPa depending on the amount of MCC used and were thermally stable up to 267 °C. The properties of these novel biofoams enable them to be strong candidates for use as tough, energy-absorbing foams, advantageously prepared using renewable-based resources.

Similar content being viewed by others

References

Avalle M, Belingardi G, Montanini R (2001) Characterization of polymeric structural foams under compressive impact loading by means of energy-absorption diagram. Int J Impact Eng 25:455–472

Belgacem MN, Gandini A (2008) Monomers, polymers and composites from renewable resources. Elsevier, Amsterdam

Bellamy LJ (1958) The infra-red spectra of complex molecules, 2nd edn. Methuen, London

Biermann U, Friedt W, Lang S, Lühs W, Machmüller G, Metzger J, Rüsch Gen Klaas M, Schäfer H, Schneider M (2000) New syntheses with oils and fats as renewable raw materials for the chemical industry. Angew Chem Int Ed Engl 39:2206–2224

Biermann U, Bornscheuer U, Meier MAR, Metzger JO, Schäfer HJ (2011) Oils and fats as renewable raw materials in chemistry. Angew Chem Int Ed Engl 50:3854–3871. doi:10.1002/anie.201002767

Christensen CH, Rass-Hansen J, Marsden CC, Taarning E, Egeblad K (2008) The renewable chemicals industry. ChemSusChem 1:283–289

Corcuera MA, Rueda L, Fernandez d’Arlas B, Arbelaiz A, Marieta C, Mondragon I, Eceiza A (2010) Microstructure and properties of polyurethanes derived from castor oil. Polym Degrad Stab 95:2175–2184

Fernandes SC, Freire CS, Silvestre AJ, Pascoal Neto C, Gandini A (2011) Novel materials based on chitosan and cellulose. Polym Int 60:875–882

Flores-Johnson EA, Li QM (2010) Indentation into polymeric foams. Int J Solids Struct 47:1987–1995

Okoroafor MO, Frisch and KC (1995) Introduction to foams and foam formation. In: Landrock AH (ed) Handbook of plastic foams. Types, manufacture and applications. Noyes Publications, New Jessey, pp 1–10

Gandini A (2008) Polymers from renewable resources: a challenge for the future of macromolecular materials. Macromolecules 41:9491–9504

Gibson LJ, Ashby MF (1999) Cellular solids: structure and properties. Cambridge University Press, Cambridge

Jankowski M, Kotełko M (2010) Dynamic compression tests of a polyurethane flexible foam as a step in modelling impact of the head to the vehicle seat head restraint. FME Trans 38:121–127

Klempner D, Sendijarevi′c V (2004) Polymeric foams and foam technology, 2nd edn. Hanser, Ohio

Li X, Pizzi A, Cangemi M, Fierro V, Celzard A (2012) Flexible natural tannin-based and protein-based biosourced foams. Ind Crops Prod 37:389–393

Lu Y, Larock RC (2009) Novel polymeric materials from vegetable oils and vinyl monomers: preparation, properties, and applications. ChemSusChem 2:136–147. doi:10.1002/cssc.200800241

Maiti SK, Gibson LJ, Ashby MF (1984) Deformation and energy absorption diagrams for cellular solids. Acta Metall 32:1963–1975

Marshall A-L, Alaimo PJ (2010) Useful products from complex starting materials: common chemicals from biomass feed stocks. Chemistry 16:4970–4980

Meckel W, Goyert W, Wieder W, Wussow H-G (2004) Thermoplastic polyurethane elastomers. In: Geoffrey H, Kricheldorf HR, Roderic PQ (eds) Thermoplastic elastomers, 3rd edn. Hanser, Munich, pp 15–44

Miléo PC, Mulinari DR, Baptista CARP, Rocha GJM, Gonçalves AR (2011) Mechanical behaviour of polyurethane from castor oil reinforced sugarcane straw cellulose composites. Procedia Eng 10:2068–2073

Nichtnennung A (1983) Polyether polyol composition, useful to produce viscoelastic polyurethane foams, comprises polyether polyols with specific hydroxyl-functionality, -number and propylene oxide content, and renewable raw materials with one hydroxyl group. patent DE102008014032A1

Paulino M, Teixeira-Dias F (2012) On the use of polyurethane foam paddings to improve passive safety in crashworthiness applications. In: Zafar F, Sharmin E (eds) Polyurethanes. Intech, Rijeka, pp 1–15

Perdomo FA, Acosta-Osorio AA, Herrera G, Vasco-Leal JF, Mosquera-Artamonov JD, Millan-Malo B, Rodriguez-Garcia ME (2013) Physicochemical characterization of seven Mexican Ricinus communis L. seeds and oil contents. Biomass Bioenerg 48:17–24

Plastemart (2011) Global polyurethane market to reach 9.6 mln tons by 2015. http://www.plastemart.com/Plastic-Technical-Article.asp?LiteratureID=1674&Paper=global-polyurethane-market-PU-foams-thermoplastic-elastomers. Accessed 1 Jul 2013

Ravey M, Pearce EM (1997) Flexible polyurethane foam. I. Thermal decomposition of a polyether-based, water-blown commercial type of flexible polyurethane foam. J Appl Polym Sci 63:47–74

Rodriguez-Perez MA, Álvarez-Láinez M, de Saja JA (2009) Microstructure and physical properties of open-cell polyolefin foams. J Appl Polym Sci 114:1176–1186

Sharma V, Kundu PP (2006) Addition polymers from natural oils—a review. Prog Polym Sci 31:983–1008

Sharma V, Kundu PP (2008) Condensation polymers from natural oils. Prog Polym Sci 33:1199–1215

Suresh KI (2013) Rigid polyurethane foams from cardanol: synthesis, structural characterization, and evaluation of polyol and foam properties. ACS Sustain Chem Eng 1:232–242

Svagan AJ, Berglund LA, Jensen P (2011) Cellulose nanocomposite biopolymer foam–hierarchical structure effects on energy absorption. ACS Appl Mater Interfaces 3:1411–1417

Tanaka R, Hirose S, Hatakeyama H (2008) Preparation and characterization of polyurethane foams using a palm oil-based polyol. Bioresour Technol 99:3810–3816

Wik VM, Aranguren MI, Mosiewicki MA (2011) Castor oil-based polyurethanes containing cellulose nanocrystals. Polym Eng Sci 51:1389–1396

Wolska A, Goździkiewicz M, Ryszkowska J (2012) Thermal and mechanical behaviour of flexible polyurethane foams modified with graphite and phosphorous fillers. J Mater Sci 47:5627–5634

Acknowledgments

FCT is gratefully acknowledged for two postdoctorate grants to A.F. Sousa (SFRH/BPD/73383/2010) and R.J.B. Pinto (SFRH/BPD/89982/2012) and for a fellowship to M. Matos (BI/UI89/5419/2011). C.S.R. Freire also acknowledges FCT/MCTES for a research grant under the program 'Investigador FCT 2012'. The authors wish to thank to PNRC of FCT for analytical instrumentation support (POCI 2010, FEDER, REEQ/515/CTM/2005 POCI) and for funding CICECO (PEst-C/CTM/LA0011/2013).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Sousa, A.F., Matos, M., Pinto, R.J.B. et al. One-pot synthesis of biofoams from castor oil and cellulose microfibers for energy absorption impact materials. Cellulose 21, 1723–1733 (2014). https://doi.org/10.1007/s10570-014-0229-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0229-z