Abstract

Although the positive effect that cellulose nanofibers (CNF) can have on paper strength is known, their effect on flocculation during papermaking is not well understood, and most relevant studies have been carried out in presence of only cationic starch. Flocculation is the key to ensuring retention of fibers, fines, and fillers, and furthermore floc properties have a great influence on paper quality. The aim of this research is to study the interactions between CNF and flocculants by assessing the effect of two types of CNF, from eucalyptus and corn, on the flocculation process induced by three different retention systems [a dual system, polyvinylamine (PVA), and cationic starch as reference]. The results showed that CNF interacted with the flocculants in different ways, affecting flocculation efficiency and floc properties. In general, addition of CNF increased floc stability and minimized overdosing effects. Moreover, presence of CNF increased floc size for given PVA dose; therefore, CNF addition could contribute to improve the wet end in the paper machine if combined with the optimal flocculant and dose.

Similar content being viewed by others

References

Ahola S, Myllytie P, Österberg M, Teerinen T, Laine J (2008) Effect of polymer adsorption on cellulose nanofibril water binding capacity and aggregation. BioResources 3:1315–1328. doi:10.1007/s10570-007-9167-3

Alcalá M, González I, Boufi S, Vilaseca F, Mutjé P (2013) All-cellulose composites from unbleached hardwood kraft pulp reinforced with nanofibrillated cellulose. Cellulose 20:2909–2921

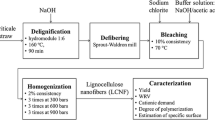

Balea A, Merayo N, Fuente E, Delgado-Aguilar M, Mutje P, Blanco A, Negro C (2016a) Valorization of corn stalk by the production of cellulose nanofibers to improve recycled paper properties. BioResources 11:3416–3431

Balea A, Blanco A, Merayo N, Negro C (2016b) Effect of nanofibrillated cellulose to reduce linting on high filler-loaded recycled papers. Appita J 69:148–156

Blanco A, Fuente E, Negro C, Tijero J (2002) Flocculation monitoring: focused beam reflectance measurement as a measurement tool. Can J Chem Eng 80:734–740

Blanco A, Negro C, Fuente E, Tijero J (2005) Effect of shearing forces and flocculant overdose on filler flocculation mechanisms and floc properties. Ind Eng Chem Res 44:9105–9112

Blanco A, Fuente E, Monte MC, Cortes N, Negro C (2009) Polymeric branched flocculant effect on the flocculation process of pulp suspensions in the papermaking industry. Ind Eng Chem Res 48:4826–4836

Boufi S, Gandini A (2015) Triticale crop residue: a cheap material for high performance nanofibrillated cellulose. RSC Adv 5:3141–3151

Bremmell KE, Jameson GJ, Biggs S (1998) Kinetic polyelectrolyte adsorption at the solid/liquid interface interaction forces and stability. Colloids Surf 139:199–211

Cadotte M, Tellier ME, Blanco A, Fuente E, Van de Ven TGM, Paris J (2007) Flocculation, retention and drainage in papermaking: a comparative study of polymeric additives. Chem Eng J 85:240–248

Delgado-Aguilar M, González I, Pèlach MA, Fuente E, Negro C, Mutje P (2015a) Improvement of deinked old newspaper/old magazine pulp suspensions by means of nanofibrillated cellulose addition. Cellulose 22:789–802

Delgado-Aguilar M, Tarrés Q, Pèlach MA, Mutjé P, Fullana-i-Palmer P (2015b) Are cellulose nanofibers a solution for a more circular economy of paper products? Environ Sci Technol 49:12206–12213

Delgado-Aguilar M, Tarrés Q, Puig J, Boufi S, Blanco Á, Mutjé P (2015c) Enzymatic refining and cellulose nanofiber addition in papermaking processes from recycled and deinked slurries. BioResources 10:5730–5743

Delgado-Aguilar M, Tovar IG, Tarrés Q, Alcalá M, Pèlach MÀ, Mutjé P (2015d) Approaching a low-cost production of cellulose nanofibers for papermaking applications. BioResources 10:5345–5355

Dimic-Misic K, Hummel M, Paltakari J, Sixta H, Maloney T, Gane P (2015) From colloidal spheres to nanofibrils: extensional flow properties of mineral pigment and mixtures with micro and nanofibrils under progressive double layer suppression. J Colloid Interface Sci 446:31–43

Eklund D, Lindström T (1991) Paper chemistry: an introduction. DT Paper Science Publications, Grankulla

Eriksen O, Syverud K, Gregersen O (2008) The use of microfibrillated cellulose produced from kraft pulp as strength enhancer in TMP paper. Nord Pulp Pap Res J 23:299–304

Fan A, Turro NJ, Somasundaran P (2000) A study of dual polymer flocculation. Colloids Surf 162:141–148

Fuente E (2004) Mecanismos y cinética de los procesos de floculación en la fabricación de papel. Dissertation, Complutense University of Madrid

Future Markets, Inc. (2015) Nanocellulose patents and publications. Published in The Global Market for Nanocellulose, 32–34. http://www.futuremarketsinc.com/the-global-market-for-nanocellulose-to-2024/. Accessed 1 April 2015

Gonzalez I, Alcala M, Chinga-Carrasco G, Vilaseca F, Boufi S, Mutje P (2014) From paper to nanopaper: evolution of mechanical and physical properties. Cellulose 21:2599

González I, Boufi S, Pèlach MA, Alcalà M, Vilaseca F, Mutjé P (2012) Nanofibrillated cellulose as paper additive in eucalyptus pulps. BioResources 7:5167–5180

Habibi Y, Chanzy H, Vignon MR (2006) TEMPO-mediated surface oxidation of cellulose whiskers. Cellulose 13:679–687

Hassan ML, Hassan EA, Oksman KN (2011) Effect of pretreatment of bagasse fibers on the properties of chitosan/microfibrillated cellulose nanocomposites. J Mater Sci 46:1732–1740

Henriksson M, Berglund LA, Isaksson P, Lindström T, Nishino T (2008) Cellulose nanopaper structures of high toughness. Biomacromolecules 9:1579–1585

ISO 5351 (2010) Pulps: determination of limiting viscosity number in cupri-ethylene-diamine (CED). International Organization for Standardization, Geneva

Jonoobi M, Mathew AP, Oksman K (2012) Producing low-cost cellulose nanofiber from sludge as new source of raw materials. Ind Crops Prod 40:232–238

Lavoine N, Desloges I, Bras J (2014) Microfibrillated cellulose coatings as new release systems for active packaging. Carbohydr Polym 103:528–537. doi:10.1002/app.40106

Lindström T (2014) B3 bio-based materials: opportunities for challenge-led innovation. Horizon 2020 expert paper, pp 1–10

Liu DY, Sui GX, Bhattacharyya D (2014) Synthesis and characterisation of nanocellulose-based polyaniline conducting films. Compos Sci Technol 99:31–36

Marx-Figini M (1978) Significance of the intrinsic viscosity ratio of unsubstituted and nitrated cellulose in different solvents. Angew Makromol Chem 72:161–171

Moral A, Monte MC, Cabeza E, Blanco A (2010) Morphological characterization of pulps to control paper properties. Cellul Chem Technol 44:473–480

Nechyporchuk O, Naceur Belgacem M, Bras J (2016) Production of cellulose nanofibrils: a review of recent advances. Ind Crops Prod 93:2–25

Norell M, Johansson K, Persson M (1999) Papermaking science and technology, vol 4. Tappi Press, Helsinki

Petroudy SRD, Syverud K, Chinga-Carrasco G, Ghasemain A, Resalati H (2014) Effects of bagasse microfibrillated cellulose and cationic polyacrylamide on key properties of bagasse paper. Carbohydr Polym 99:311–318. doi:10.1016/j.carbpol.2013.07.073

Pruden B (2005) The effect of fines on paper properties. Paper Tech 46:19–26

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8:2485–2491

Song HN, Ankerfors M, Hoc M, Lindstrom T (2010) Reduction of the linting and dusting propensity of newspaper using starch and microfibrillated cellulose. Nord Pulp Paper Res J 25:495

Stén M (1999) Papermaking chemistry, papermaking science and technology, vol 4. Tappi Press, Helsinki

Taipale T, Osterberg M, Nykanen A, Ruokolainen J, Laine J (2010) Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 17:1005–1020

Acknowledgements

The authors wish to thank the Economy and Competitiveness Ministry of Spain for support of this project with reference CTQ2012-36868-C02-01.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Merayo, N., Balea, A., de la Fuente, E. et al. Interactions between cellulose nanofibers and retention systems in flocculation of recycled fibers. Cellulose 24, 677–692 (2017). https://doi.org/10.1007/s10570-016-1138-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-1138-0