Abstract

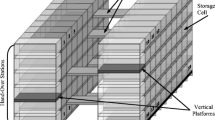

We consider multiple factors of allocating yard storage space to export containers in a terminal under heavy workloads and with a limited yard storage capacity. We aim at expediting container handling in yards and thus we attempt to balance workloads, shorten yard-to-berth transport distances and minimize the number of sub-blocks with handling jobs. To tackle various objectives in this yard storage allocation, we introduce a hierarchical analytical method that decomposes the planning procedure into two stages. We first optimize workload distribution across the whole yard. Thereafter, we propose a flexible yard allocation strategy and attempt to stack export containers into a minimum number of sub-blocks in the yard so as to facilitate yard crane operation and increase yard space utilization. We present integer programming formulations for these two sub-problems and then solve these two models iteratively by introducing additional parameters and constraints into the formulations. Experimental results indicate that this method is efficient and effective in obtaining good storage templates in the yard by achieving minimum handling time for export containers. Further discussions explore the results of yard space utilization and busy rate in yard blocks when providing different sizes of sub-blocks that contributes to the setting up of suitable sub-blocks in a terminal according to the capacity of its storage space and container handling devices.

Similar content being viewed by others

References

Chen T (1999) Yard operations in the container terminal—a study in the ‘unproductive moves’. Marit Policy Manag 26(1):27–38

Dekker R, Voogd P, van Asperen E (2006) Advanced methods for container stacking. OR Spectr 28(4):563–586

Han Y, Lee LH, Chew EP, Tan KC (2008) A yard storage strategy for minimizing traffic congestion in a marine container transshipment hub. OR Spectr 30(4):697–720

Jiang X, Chew EP, Lee LH, Tan KC (2013) Flexible space-sharing strategy for storage yard management in a transshipment hub port. OR Spectr 35(2):417–439

Kim KH (1997) Evaluation of the number of rehandles in container yards. Comput Ind Eng 32(4):701–711

Kim KH, Kim HB (1999) Segregating space allocation models for container inventories in port container terminals. Int J Prod Econ 59(1–3):415–423

Kim KH, Kim HB (2002) The optimal sizing of the storage space and handling facilities for import containers. Transp Res Part B 36(9):821–835

Kim KH, Park KT (2003) A note on a dynamic space-allocation method for outbound containers. Eur J Oper Res 148(1):92–101

Kim KH, Park YM, Jin MJ (2008) An optimal layout of container yards. OR Spectr 30(4):675–695

Kozan E, Preston P (2006) Mathematical modelling of container transfers and storage locations at seaport terminals. OR Spectr 28(4):519–537

Ku LP, Chew EP, Lee LH, Tan KC (2012) A novel approach to yard planning under vessel arrival uncertainty. Flex Serv Manuf J 24(3):274–293

Lee LH, Chew EP, Tan KC, Han Y (2006) An optimization model for storage yard management in transshipment hubs. OR Spectr 28(4):539–561

Li MK, Yip TL (2013) Joint planning for yard storage space and home berths in container terminals. Int J Prod Res 51(10):3143–3155

Ng WC, Mak KL, Li MK (2010) Yard planning for vessel services with a cyclical calling pattern. Eng Optim 42(11):1039–1054

Petering MEH (2009) Effect of block width and storage yard layout on marine container terminal performance. Transp Res Part E 45(4):591–610

Petering MEH, Murty KG (2009) Effect of block length and yard crane deployment systems on overall performance at a seaport container transshipment terminal. Comput Oper Res 36(5):1711–1725

Preston P, Kozan E (2001) An approach to determine storage locations of containers at seaport terminals. Comput Oper Res 28:983–995

Stahlbock R, Voß S (2008) Operations research at container terminals: a literature update. OR Spectr 30(1):1–52

Steenken D, Voss S, Stahlbock R (2004) Container terminal operation and operations research—a classification and literature review. OR Spectr 26(1):3–49

Vis IFA (2006) A comparative analysis of storage and retrieval equipment at a container terminal. Int J Prod Econ 103(2):680–693

Zhang C, Liu J, Wan YW, Murty KG, Linn RJ (2003) Storage space allocation in container terminals. Transp Res Part B Methodol 37(10):883–903

Zhen L (2013) Yard template planning in transshipment hubs under uncertain berthing time and position. J Oper Res Soc 64:1418–1428

Zhen L (2014) Storage allocation in transshipment hubs under uncertainties. Int J Prod Res 52(1):72–88. doi:10.1080/00207543.2013.828166

Acknowledgment

This research is sponsored by Shanghai Pujiang Program under grant 13PJC064.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, MK. Yard storage planning for minimizing handling time of export containers. Flex Serv Manuf J 27, 285–299 (2015). https://doi.org/10.1007/s10696-014-9193-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10696-014-9193-z