Abstract

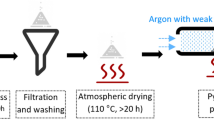

The preparation and oxygen permeation properties of the (Ce0.8Pr0.2)O2−δ − x vol% MnFe2O4 composites, where x = 0 to 35, have been investigated. The samples were prepared by the Pechini method. In the case of Ce0.8Pr0.2O2−δ, an oxygen flux density of 6 μmol⋅cm−2⋅s−1 (L = 0.0247 cm) and the maximum methane conversion of 50% were attained at 1000∘C. Unlike composites consisting of Gd-doped CeO2 and MnFe2O4, the oxygen permeability of the (Ce0.8Pr0.2)O2−δ – x vol% MnFe2O4 composites was almost constant regardless of the volume fraction of MnFe2O4; however, the optimum volume fraction of MnFe2O4 was determined to be 5 to 25 in the context of the chemical and mechanical stabilities under methane conversion atmosphere. In addition, the surface modification of the (Ce0.8Gd0.2)O2−δ – 15 vol% MnFe2O4 composite was performed by using the FePt nanoparticles. The catalyst loading of 2.8 mg/cm2 on the both side of the 0.3 mm-thick (Ce0.8Gd0.2)O2−δ – 15vol% MnFe2O4 composite increased the oxygen flux density from 0.30 to 0.76 μmol⋅cm−2⋅s−1 in the case of He/air gradients; however, the effect seems to be reduced in the case of high oxygen flux density caused by a large pO2 gradient. Moreover, the Langmuir-Blodgett film of the FePt nanoparticles were successfully prepared on the tape-cast (Ce0.8Gd0.2)O2−δ – 15vol% MnFe2O4 composite. Hydrophobic treatments for the surface of the composite were crucial to achieve high transfer ratio for the deposition of the LB film.

Similar content being viewed by others

References

Y. Teraoka, H.M. Zhang, S. Furukawa, and N. Yamazoe, Chemistry Letters, 1743 (1985).

P.N. Dyer, R.E. Richards, S.L. Russek, and D.M. Taylor, Solid State Ionics, 134, 21 (2000).

Z.P. Shao, G.X. Xiong, H. Dong, W.H. Yang, and L.W. Lin, Separation and Purification Technology, 25, 97 (2001).

T. Ishihara, Y. Tsuruta, T. Todaka, H. Nishiguchi, and Y. Takita, Solid State Ionics, 152, 709 (2002).

H. Takamura, K. Enomoto, Y. Aizumi, A. Kamegawa, and M. Okada, Solid State Ionics, 175, 379 (2004).

V.V. Kharton, A.V. Kovalevsky, A.P. Viskup, F.M. Figueiredo, A.A. Yaremchenko, E.N. Naumovich, and F.M.B. Marques, Journal of the European Ceramic Society, 21, 1763 (2001).

U. Nigge, H.D. Wiemhofer, E.W.J. Romer, H.J.M. Bouwmeester, and T.R. Schulte, Solid State Ionics, 146, 163 (2002).

H. Takamura, M. Kawai, K. Okumura, A. Kamegawa, and M. Okada, in Preparation and Oxygen Permeability of Gd-Doped Ceria and Spinel-Type Ferrite Composites (Materials Research Society, Boston, USA, 2002), pp. EE8.11.1.

H. Takamura, K. Okumura, Y. Koshino, A. Kamegawa, and M. Okada, Journal of Electroceramics, 13, 613 (2004).

T.S. Stefanik and H.L. Tuller, Journal of Electroceramics, 13, 799 (2004).

P. Shuk and M. Greenblatt, Solid State Ionics, 116, 217 (1999).

D.P. Fagg, V.V. Kharton, A. Shaula, I.P. Marozau, and J.R. Frade, Solid State Ionics, 176, 1723 (2005).

H. Takamura and H.L. Tuller, Solid State Ionics, 134, 67 (2000).

H. Takamura, K. Enomoto, A. Kamegawa, and M. Okada, Solid State Ionics, 154, 581 (2002).

C. Kleinlogel and L.J. Gauckler, Solid State Ionics, 135, 567 (2000).

S.H. Sun, C.B. Murray, D. Weller, L. Folks, and A. Moser, Science, 287, 1989 (2000).

H. Takamura, T. Kobayashi, T. Kasahara, A. Kamegawa, and M. Okada, Journal of Alloys and Compounds, 408–412, 1084 (2006).

H.I. Yoo and H.L. Tuller, Journal of Materials Research, 3, 552 (1988).

G. Bonsdorf, K. Schafer, K. Teske, H. Langbein, and H. Ullmann, Solid State Ionics, 110, 73 (1998).

Y. Takasu, T. Sugino, and Y. Matsuda, Journal of Applied Electrochemistry, 14, 79 (1984).

M. Nauer, C. Ftikos, and B.C. H. Steele, Journal of the European Ceramic Society, 14, 493 (1994).

A.E. Sovestnov, V.A. Shaburov, B.T. Melekh, I.A. Smirnov, Y.P. Smirnov, A.V. Tyunis, and A. I. Egorov, Fizika Tverdogo Tela, 36, 1140 (1994).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Takamura, H., Sugai, H., Watanabe, M. et al. Oxygen permeation properties and surface modification of acceptor-doped CeO2/MnFe2O4 composites. J Electroceram 17, 741–748 (2006). https://doi.org/10.1007/s10832-006-7776-0

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s10832-006-7776-0