Abstract

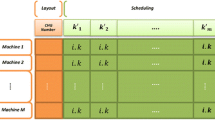

This paper addresses part scheduling problems (CPS problems) in the context of the need for exceptional parts to visit machines among cells and to be transferred via an automated guided vehicle (AGV) in order to minimize the process make-span. A nonlinear mathematical programming model is proposed to determine the sequences of the parts processed on the machines, which is solved by a two-stage heuristic algorithm. Because of the complexity of the CPS problem, it is divided into two sub-problems: the Intra-cell part scheduling problem (Intra-CPS) and the Inter-CPS. The two-stage heuristic algorithm consists of a local search combined genetic algorithm (LSC-GA) whose neighborhood is based on the disjunctive graph model and a heuristic algorithm for finding a lower make-span through roulette selection (LMW-HEU). When solving the Intra-CPS problem, the sequence of parts processed by each machine and the sequence of parts to be transferred by AGV within manufacturing cells are determined cell by cell by the LSC-GA. Then, the sequence of parts from different cells that need to be processed on the same machine is determined by LMW-HEU in the Inter-CPS problem. A series of experiments were conducted to test the two-stage algorithm. The results demonstrate the effectiveness of the proposed two-stage algorithm.

Similar content being viewed by others

References

Abdelmaguid, T. F., Nassef, A. O., Kamal, B. A., & Hassan, M. F. (2004). A hybrid GA/heuristic approach to the simultaneous scheduling of machines and automated guided vehicles. International Journal of Production Research, 42(2), 267–281.

Alfieri, A., Cantamessa, M., Monchiero, A., & Montagna, F. (2012). Heuristics for puzzle-based storage systems driven by a limited set of automated guided vehicles. Journal of Intelligent Manufacturing, 23(5), 1695–1705.

Blazewicz, J., Pesch, E., & Sterna, M. (2000). The disjunctive graph machine representation of the job shop scheduling problem. European Journal of Operational Research, 127(2), 317–331.

Cakar, T., Yildirim, M. B., & Barut, M. (2005). A neuro-genetic approach to design and planning of a manufacturing cell. Journal of Intelligent Manufacturing, 16(4–5), 453–462.

Caumond, A., Lacomme, P., Moukrim, A., & Tchernev, N. (2009). An MILP for scheduling problems in an FMS with one vehicle. European Journal of Operational Research, 199(3), 706–722.

Chaudhry, I. A., Mahmood, S., & Shami, M. (2011). Simultaneous scheduling of machines and automated guided vehicles in flexible manufacturing systems using genetic algorithms. Journal of Central South University of Technology, 18(5), 1473–1486.

Chen, C. J., & Tseng, C. S. (1996). The path and location planning of workpieces by genetic algorithms. Journal of Intelligent Manufacturing, 7(1), 69–76.

Deroussi, L., Gourgand, M., & Tchernev, N. (2008). A simple metaheuristic approach to the simultaneous scheduling of machines and automated guided vehicles. International Journal of Production Research, 46(8), 2143–2164.

Elmi, A., Solimanpur, M., & Topaloglu, S. (2011). A simulated annealing algorithm for the job shop cell scheduling problem with intercellular moves and reentrant parts. Computer & Industrial Engineering, 61(1), 171–178.

Engin, O., Ceran, G., & Yilmaz, M. K. (2011). An efficient genetic algorithm for hybrid flow shop scheduling with multiprocessor task problems. Applied Soft Computing, 11(3), 3056–3065.

Hendizadeh, H., Faramarzi, H., Mansouri, S. A., Gupta, J. N. D., & Elmekkawy, T. Y. (2008). Meta-heuristics for scheduling a flowshop manufacturing cell with sequence dependent family setup times. International Journal of Production Economics, 111(2), 593–605.

Hong, K. S., Yeo, S., Kim, H., Chew, E., & Lee, C. (2012). Integrated inventory and transportation decision for ubiquitous supply chain management. Journal of Intelligent Manufacturing, 23(4), 977–988.

Hurink, J., & Knust, S. (2002). A tabu search algorithm for scheduling a single robot in a job-shop environment. Discrete Applied Mathematics, 119(1–2), 181–203.

Hurink, J., & Knust, S. (2005). Tabu search algorithms for job-shop problems with a single transport robot. European Journal of Operational Research, 162(1), 99–111.

Kaku, I., Gong, J., Tang, J. F., & Yin, Y. (2009). Modeling and numerical analysis of line-cell conversion problems. International Journal of Production Research, 47(8), 2055–2078.

Kaku, I., Gong, J., Tang, J. F., & Yin, Y. (2011). A review: practice and theory in line-cell conversion. Assembly Line-Theory and Practice, 107–130.

Khilwani, N., Ulutas, B. H., Islier, A. A., & Tiwari, M. K. (2011). A methodology to design virtual cellular manufacturing systems. Journal of Intelligent Manufacturing, 22(4), 533–544.

Lacomme, P., Larabi, M., & Tchernev, N. (2013). Job-shop based framework for simultaneous scheduling of machines and automated guided vehicles. International Journal of Production Economics, 143(1), 24–34.

Landry, S. J. (2011). Human centered design in the air traffic control system. Journal of Intelligent Manufacturing, 22(1), 65–72.

Li, D. N., Wang, Y., & Xiao, G. X. (2013). Dynamic parts scheduling in multiple job shop cells considering intercell moves and flexible routes. Computers & Operations Research, 40(5), 2007–2023.

Lin, S. W., Ying, K. C., Lu, C. C., & Gupta, J. N. D. (2011). Applying multi-start simulated annealing to schedule a flowline manufacturing cell with sequence dependent family setup times. International Journal of Production Economics, 130(2), 246–254.

Naderi, B., Zandieh, M., & Fatemi Ghomi, S. M. T. (2009). Scheduling job shop problems with sequence-dependent setup times. International Journal of Production Research, 47(21), 5959–5976.

Reddy, B. S. P., & Rao, C. S. P. (2006). A hybrid multi-objective GA for simultaneous scheduling of machines and AGVs in FMS. International Journal of Advanced Manufacturing Technology, 31(5–6), 602–613.

Ren, Q. D. E. J., & Wang, Y. P. (2012). A new hybrid genetic algorithm for job shop scheduling problem. Computers & Operations Research, 39(10), 2291–2299.

Saravanan, M., & Haq, A. N. (2008). A scatter search method to minimise make-span of cell scheduling problem. International Journal of Agile Systems and Management, 3(1–2), 18–36.

Schaller, J. (2000). A comparison of heuristics for family and job scheduling in a flow-line manufacturing cell. International Journal of Production Research, 38(2), 287–308.

Schrich, C. R., Armentano, V. A., & Laguna, M. (2004). Tardiness minimization in a flexible job shop: A tabu search approach. Journal of Intelligent Manufacturing, 15(1), 103–115.

Selim, H. M., Askin, R. G., & Vakharia, A. J. (1998). Cell formation in group technology: Review, evaluation and directions for future research. Computers & Industrial Engineering, 34(1), 3–20.

Solimanpur, M., Vrat, P., & Shankar, R. (2004). A Heuristic to minimize makespan of cell scheduling problem. International Journal of Production Economics, 88(3), 231–241.

Suer, G. A. (1992). An algorithm to find the number of parallel stations for optimal cell scheduling. Computers & Industrial Engineering, 23(1–4), 81–84.

Taha, Z., & Rostam, S. (2012). A hybrid fuzzy AHP-PROMETHEE decision support system for machine tool selection in flexible manufacturing cell. Journal of Intelligent Manufacturing, 23(6), 2137–2149.

Tang, J. F., Wang, X., Kaku, I., & Yung, K. L. (2010). Optimization of parts scheduling in multiple cells considering intercell move using scatter search approach. Journal of Intelligent Manufacturing, 21(4), 525–537.

Tavakkoli-Moghaddam, R., Javadian, N., Khorrami, A., & Gholipour-Kanani, Y. (2010). Design of a scatter search method for a novel multi-criteria group scheduling problem in a cellular manufacturing system. Expert Systems with Applications, 37(3), 2661–2669.

Ulusoy, G., Sivrikaya-Serifoglus, F., & Bilge, U. (1997). A genetic algorithm approach to the simultaneous scheduling of machines and automated guided vehicles. Computers & Operations Research, 24(4), 335–351.

Yu, J. J., Sun, S. D., Si, S. B., Yang, H. G., & Wu, X. L. (2007). A study on the aviation manufacture cell scheduling based on adaptive ant colony algorithm. Materials Science Forum, 532–533, 1060–1063.

Zhang, R., Chang, P. C., & Wu, C. (2013). A hybrid genetic algorithm for the job shop scheduling problem with practical considerations for manufacturing costs: Investigations motivated by vehicle production. International Journal of Production Economics, 145(1), 38–52.

Zhang, C. Y., Li, P. G., Guan, Z. L., & Rao, Y. Q. (2007). A tabu search algorithm with a new neighborhood structure for the job shop scheduling problem. Computers & Operations Research, 34(11), 3229–3242.

Zhang, Q., Manier, H., & Manier, M. A. (2012). A genetic algorithm with tabu search procedure for flexible job shop scheduling with transportation constraints and bounded processing times. Computers & Operations Research, 39(7), 1713–1723.

Acknowledgments

This paper is financially supported by the National Natural Science Foundation of China (NSFC 71021061).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zeng, C., Tang, J. & Yan, C. Job-shop cell-scheduling problem with inter-cell moves and automated guided vehicles. J Intell Manuf 26, 845–859 (2015). https://doi.org/10.1007/s10845-014-0875-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-014-0875-x