Abstract

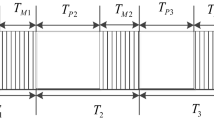

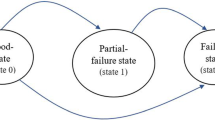

While there has been considerable work over the years on the basic deterministic economic production quantity (EPQ) and its derivative models, there have been few extensions of these models that recognize the potential effects of machine degradation. As maintenance activities can keep machines in good operation, it should be integrated into EPQ models to meet real situations. Due to machine degradation, this paper integrates predictive maintenance into EPQ model in which autoregressive integrated moving average model is adopted to predict system’s healthy indicator. Moreover, two kinds of system out-of-control states are considered in this proposed EPQ model: in State I, the system produces non-conforming items; and in State II, the system fails. Aiming at minimizing the expected average total cost and optimizing the EPQ, suitable maintenance intervals and frequency are determined prior to any predicted failure. Finally, a case study is presented and the computational results are discussed to show the efficiency of this integrated EPQ model.

Similar content being viewed by others

References

Anis, C., Nidhal, R., & Mehdi, R. (2008). Simultaneous determination of production lot size and preventive maintenance schedule for unreliable production system. Journal of Quality in Maintenance Engineering, 14(2), 161–176.

Ben-Daya, M. (2002). The economic production lot-sizing problem with imperfect production processes and imperfect maintenance. International Journal of Production Economics, 76(3), 257–264.

Ben-Daya, M., & Noman, S. A. (2006). Lot sizing, preventive maintenance, and warranty decisions for imperfect production systems. Journal of Quality in Maintenance Engineering, 12(1), 68–80.

Ben-Daya, M., & Darwish, M. A. (2007). Effect of inspection errors and preventive maintenance on a two-stage production inventory system. International Journal of Production Economics, 107, 301–313.

Chiu, S. W., Lin, H.-D., Wu, M.-F., & Yang, J-Ch. (2011). Determining replenishment lot size and shipment policy for an extended EPW model with delivery and quality assurance issues. Scientia Iranica E, 18(6), 1537–1544.

Dohi, T., Okamura, H., & Osaki, S. (2001). Optimal control of preventive maintenance schedule and safety stocks in an unreliable manufacturing environment. International Journal of Production Economics, 74(1–3), 147–155.

El-Ferik, S. (2008). Economic production lot-sizing for an unreliable machine under imperfect age-based maintenance policy. European Journal of Operational Research, 186(1), 150–163.

Gebraeel, N. Z., & Lawley, M. A. (2008). A neural network degradation model for computing and updating residual life distributions. IEEE Transactions on Automation Science and Engineering, 5(1), 154–163.

Hariga, M., & Ben-Daya, M. (1998). Note: The economic manufacturing lot-sizing problem with imperfect production process: Bounds and optimal solutions. Naval Research Logistics, 45(4), 423–433.

Huang, R., Xi, L., Liu, C., Qiu, H., & Lee, J. (2007). Residual life predictions for ball bearings based on self-organizing map and back propagation neural network methods. Mechanical Systems and Signal Processing, 21(1), 193–207.

Kiamars, F. H., Changiz, V., & Alireza, K. (2012). Retracted: Using genetic algorithm approach to solve a multi-product EPQ model with defective items, rework, and constrained space. Journal of Industrial Engineering, 8(1), 27.

Lee, J., Jun, N., Dragan, D., Qiu, H., & Liao, H. (2006). Intelligent prognostics tools and e-maintenance. Computers in Industry, 57(6), 476–489.

Lee, H. L., & Rosenblatt, M. J. (1989). A production and maintenance planning model with restoration cost dependent on detection delay. IIE Transactions, 21(4), 368–375.

Lee, H. -S., & Srinivasan, M. M. (2001). A production/inventory policy for an unreliable machine. In M. A. Rahim & M. Ben-Daya (Eds.), Integrated models in production planning, inventory, quality, and maintenance (pp. 79–94). Norwell, MA: Kluwer Academic Publishers.

Liao, W. Z., Pan, E. S., & Xi, L. F. (2010). Preventive maintenance scheduling for repairable system with deterioration. Journal of Intelligent Manufacturing, 21, 875–884.

Liu, J., Dragan, D., Ni, J., Casoetto, N., & Lee, J. (2007). Similarity based method for manufacturing process performance prediction and diagnosis. Computers in Industry, 58(6), 558–566.

Lu, H., Kolarik, W. J., & Lu, S. S. (2001). Real-time performance reliability prediction. IEEE Transactions on Reliability, 50(4), 353–357.

Lu, S., Tu, Y., & Lu, H. (2007). Predictive condition-based maintenance for continuously deteriorating systems. Quality and Reliability Engineering International, 23(1), 71–81.

Mehdi, R., Nidhal, R., & Anis, C. (2010). Joint quality control and preventive maintenance strategy for imperfect production processes. Journal of Intelligent Manufacturing, 21(2), 205–212.

Pham, H., & Wang, H. (1996). Imperfect maintenance. European Journal of Operational Research, 94(3), 425–438.

Porteus, E. L. (1986). Optimal lot sizing, process quality improvement and setup cost reduction. Operations Research, 34(1), 137–144.

Rosenblatt, M. J., & Lee, H. L. (1986). Economic Production Cycles With Imperfect Production Process. IIE Transactions, 18(1), 48–55.

Ross, S. M. (1970). Applied probability models with optimization applications. Mineola: Courier Dover Publications.

Ruschin-Rimini, N., Maimon, O., & Romano, R. (2009). Visual analysis of quality-related manufacturing data using fractal geometry. Journal of Intelligent Manufacturing, 23(3), 481–495.

Sheu, S. H., & Chen, J. (2004). Optimal lot-sizing problem with imperfect maintenance and imperfect production. International Journal of Systems Science, 35(1), 69–77.

Shumway, R. H., & Stoffer, D. S. (2006). Time series analysis and its applications with R examples (2nd ed.). New York: Springer Texts in Statistics.

Singa, W. C., Dah-Chuan, G., & Hui-Ming, W. (2004). Effects of random defective rate and imperfect rework process on economic production quantity model. Japan Journal of Industrial and Applied Mathematics, 21(3), 375–389.

Taft, E. W. (1918). The most economical production lot. Iron Age, 101, 1410–1412.

Wang, C. H. (2004). The impact of a free-repair warranty policy on EMQ model for imperfect production systems. Computers & Operations Research, 31(12), 2021–2035.

Wang, C. H., & Sheu, S. H. (2003). Optimal lot sizing for products sold under free-repair warranty. European Journal of Operational Research, 149(1), 131–141.

Yan-Chun, Chen. (2013). An optimal production and inspection strategy with preventive maintenance error and rework. Journal of Manufacturing Systems, 32, 99–106.

Yang, S. (1991). Time series analysis in engineering. Wuhan: Huazhong University of Technology Press.

Yang, S. K. (2003). A condition-based failure-prediction and processing-scheme for preventive maintenance. IEEE Transactions on Reliability, 52(3), 373–383.

Yang, Z., Djurdjanovic, D., & Ni, J. (2008). Maintenance scheduling in manufacturing systems based on predicted machine degradation. Journal of Intelligent Manufacturing, 19(1), 87–98.

Yeh, R. H., & Chen, T. H. (2006). Optimal lot size and inspection policy for products sold with warranty. European Journal of Operational Research, 174(2), 766–776.

Yesser, Y., Anis, C., & Nidhal, R. (2012). Quasi-optimal integrated production, inventory and maintenance policies for a single-vendor single-buyer system with imperfect production process. Journal of Intelligent Manufacturing, 23, 1245–1256.

Xia, T. B., Jin, X. N., Xi, L. F., Zhang, Y. J., & Ni, J. (2013) Operating load based real-time rolling grey forecasting for machine health prognosis in dynamic maintenance schedule. Journal of Intelligent Manufacturing. doi:10.1007/s10845-013-0780-8.

Xu, Z., Ji, Y., & Zhou, D. (2009). A new real-time reliability prediction method for dynamic systems based on on-line fault prediction. IEEE Transactions on Reliability, 58(3), 523–538.

Acknowledgments

The authors would like to thank anonymous referees for their remarkable comments and great supported by National Natural Science Foundation of China (50875168, 71301176), Natural Science Foundation of Shanghai, China (Grant No. 12ZR1414400), Fundamental Research Funds for the Central Universities (CDJZR12110004), and Research Fund for the Doctoral Program of Higher Education (20130191120001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wen, D., Ershun, P., Ying, W. et al. An economic production quantity model for a deteriorating system integrated with predictive maintenance strategy. J Intell Manuf 27, 1323–1333 (2016). https://doi.org/10.1007/s10845-014-0954-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-014-0954-z