Abstract

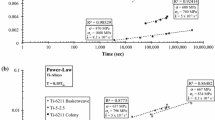

Creep experiments were conducted on single crystals of very high purity aluminum to evaluate the validity of the Harper–Dorn region of flow which occurs at very low stresses and high homologous temperatures. The results confirm the existence of a different flow process under these conditions but with a stress exponent closer to ∼3 rather than 1. Measurements show that the dislocation density within this low stress region varies with stress in a manner consistent with the behavior anticipated from an extrapolation of data reported in the regime of conventional power-law creep at high stresses. All of the experimental results are in reasonable agreement with earlier published data, including with the original data of Harper and Dorn when their results are plotted without incorporating a threshold stress.

Similar content being viewed by others

References

Bird JE, Mukherjee AK, Dorn JE (1969) In: Brandon DG, Rosen A (eds) Quantitative relation between properties and microstructure. Israel Universities Press, Jerusalem, Israel, p 255

Langdon TG (2002) Metall Mater Trans 33A:249

Weertman J (1957) J Appl Phys 28:1185. doi:https://doi.org/10.1063/1.1722604

Weertman J (1955) J Appl Phys 26:1213. doi:https://doi.org/10.1063/1.1721875

Mohamed FA, Langdon TG (1974) Acta Metall 22:779. doi:https://doi.org/10.1016/0001-6160(74)90088-1

Yavari P, Langdon TG (1982) Acta Metall 30:2181. doi:https://doi.org/10.1016/0001-6160(82)90139-0

Cannon WR, Langdon TG (1983) J Mater Sci 18:1. doi:https://doi.org/10.1007/BF00543808

Cannon WR, Langdon TG (1988) J Mater Sci 23:1. doi:https://doi.org/10.1007/BF01174028

Nabarro FRN (1948) Report of a conference on strength of solids. The Physical Society, London, UK, p 75

Herring C (1950) J Appl Phys 21:437. doi:https://doi.org/10.1063/1.1699681

Coble RL (1963) J Appl Phys 34:1679. doi:https://doi.org/10.1063/1.1702656

Harper J, Dorn JE (1957) Acta Metall 5:654. doi:https://doi.org/10.1016/0001-6160(57)90112-8

Barrett CR, Muehleisen EC, Nix WD (1972) Mater Sci Eng 10:33. doi:https://doi.org/10.1016/0025-5416(72)90063-8

Mohamed FA, Murty KL, Morris JW (1973) Metall Trans 4:935. doi:https://doi.org/10.1007/BF02645593

Mohamed FA, Langdon TG (1974) Metall Trans 5:2339. doi:https://doi.org/10.1007/BF02644014

Kumar P, Kassner ME, Langdon TG (2007) J Mater Sci 42:409. doi:https://doi.org/10.1007/s10853-006-0782-4

Murty KL, Mohamed FA, Dorn JE (1972) Acta Metall 20:1009. doi:https://doi.org/10.1016/0001-6160(72)90135-6

Murty KL (1974) Mater Sci Eng 14:169. doi:https://doi.org/10.1016/0025-5416(74)90010-X

Mohamed FA (1978) Metall Trans 9A:1343

Yavari P, Mohamed FA, Langdon TG (1981) Acta Metall 29:1495. doi:https://doi.org/10.1016/0001-6160(81)90184-X

Yavari P, Miller DA, Langdon TG (1982) Acta Metall 30:871. doi:https://doi.org/10.1016/0001-6160(82)90085-2

Mohamed FA, Ginter TJ (1982) Acta Metall 30:1869. doi:https://doi.org/10.1016/0001-6160(82)90027-X

Lee S, Ardell AJ (1985) In: McQueen HJ, Bailon J-P, Dickson JI, Jonas JJ, Akben MG (eds) Strength of metals and alloys (ICSMA 7), vol 1. Pergamon Press, Oxford, UK, p 671

Ginter TJ, Chaudhury PK, Mohamed FA (2001) Acta Mater 49:263. doi:https://doi.org/10.1016/S1359-6454(00)00316-5

Ginter TJ, Mohamed FA (2002) Mater Sci Eng A322:148. doi:https://doi.org/10.1016/S0921-5093(01)01127-3

Srivastava V, McNee KR, Jones H, Greenwood GW (2005) Mater Sci Tech 21:701

Mohamed FA (2007) Mater Sci Eng A463:177. doi:https://doi.org/10.1016/j.msea.2006.06.142

Muehleisen EC, Barrett CR, Nix WD (1970) Scripta Metall 4:995. doi:https://doi.org/10.1016/0036-9748(70)90047-5

Burton B (1972) Phil Mag 25:645. doi:https://doi.org/10.1080/14786437208228897

Blum W, Maier W (1999) Phys Stat Sol (a) 171:467. doi:10.1002/(SICI)1521-396X(199902)171:2<467::AID-PSSA467>3.0.CO;2-8

McNee KR, Jones H, Greenwood GW (2001) In: Parker JD (ed) Creep and fracture of engineering materials and structures. The Institute of Materials, London, UK, p 185

Evans AG, Langdon TG (1976) Prog Mater Sci 21:171. doi:https://doi.org/10.1016/0079-6425(76)90006-2

Bailey JE, Hirsch PB (1960) Phil Mag 5:485. doi:https://doi.org/10.1080/14786436008238300

Horiuchi R, Otsuka M (1972) Trans Japan Inst Metals 13:284

Kumar P, Kassner ME, Blum W, Eisenlohr P, Langdon TG (2008) Mater Sci Eng (in press)

Kassner ME, McMahon ME (1987) Metall Trans 18A:835

Lin P, Lee SS, Ardell AJ (1986) Acta Metall 37:739. doi:https://doi.org/10.1016/0001-6160(89)90257-5

Blum W (1993) In: Cahn RW, Hassen P, Kramer EJ (eds) Plastic deformation and fracture. VCH Publishers, Weinheim, Germany, p 339

Straub S, Blum W (1990) Scripta Metall Mater 24:1837. doi:https://doi.org/10.1016/0956-716X(90)90036-G

Blum W, Eisenlohr P, Breutinger F (2002) Metall Mater Trans 33A:291

Acknowledgements

We thank Dr. Philip Eisenlohr and Prof. Wolfgang Blum (University of Erlangen-Nürnberg) for several helpful discussions. This work was supported by the Lawrence Livermore Laboratory under Grant B552748.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, P., Kassner, M.E. & Langdon, T.G. The role of Harper–Dorn creep at high temperatures and very low stresses. J Mater Sci 43, 4801–4810 (2008). https://doi.org/10.1007/s10853-008-2680-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2680-4