Abstract

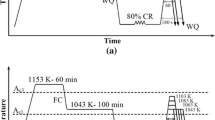

The ferrite-to-austenite phase transformation during water quenching of a duplex stainless steel was studied, where a duplex stainless steel was heated to 1370 °C (delta ferrite region) and quenched to room temperature. The microstructure consisted of coarse ferrite grains and fine needle-like austenite particles. The phase transformation mechanism appeared to be “diffusion-limited” displacive where shear was dominant, but also accompanied by prior or simultaneous diffusional elemental redistribution. A small fraction of the interfaces followed Kurdjumov–Sachs and Nishiyama–Wassermann orientation relationships (ORs) where austenite/ferrite interfaces terminated on {111}A//{110}F planes. The high undercooling associated with the fast cooling rates resulted in a considerable deviation from rational ORs. This was mostly due to the formation of intragranular austenite on Cr2N particles, which most likely caused a random OR with respect to the ferrite matrix. A detailed transmission electron microscopy (TEM) analysis revealed that the planar interphase boundaries characterised by the rational ORs typically contained one dominant set of parallel, regularly spaced dislocations. TEM analysis also showed the occurrence of small protrusions appearing on the edge/face of some austenite particles. Some of these did not leave a sub-boundary behind and formed a finger-like austenite morphology resulting from the instability mechanism. In some other cases, the protruded austenite possessed a low-angle grain boundary with the substrate austenite grain, which was the result of sympathetic nucleation of austenite on a pre-existing austenite particle.

Similar content being viewed by others

References

Schuh CA, Kumar M, King WE (2003) Analysis of grain boundary networks and their evolution during grain boundary engineering. Acta Mater 51:687–700

Randle V (2004) Twinning-related grain boundary engineering. Acta Mater 52:4067–4081

Watanabe T (2011) Grain boundary engineering: historical perspective and future prospects. J Mater Sci 46:4095–4115. https://doi.org/10.1007/s10853-011-5393-z

Farabi E, Hodgson PD, Rohrer GS, Beladi H (2018) Five-parameter intervariant boundary characterization of martensite in commercially pure titanium. Acta Mater 154:147–160

Beladi H, Rohrer GS (2017) The role of thermomechanical routes on the distribution of grain boundary and interface plane orientations in transformed microstructures. Metal. Mater. Trans. A 48:2781–2790

Gunn RN (1997) Duplex Stainless Steels: Microstructure. Woodhead Publishing, Cambridge, Properties and Applications

Haghdadi N, Cizek P, Hodgson PD, Tari V, Rohrer GS, Beladi H (2018) Effect of ferrite-to-austenite phase transformation path on the interface crystallographic character distributions in a duplex stainless steel. Acta Mater 145:196–209

Haghdadi N, Abou-Ras D, Cizek P, Hodgson PD, Rollett AD, Beladi H (2017) Austenite–ferrite interface crystallography dependence of sigma phase precipitation using the five-parameter characterization approach. Mater. Let. 196:264–268

Haghdadi N, Cizek P, Hodgson PD, Beladi H (2019) Microstructure dependence of impact toughness in duplex stainless steels. Mater Sci Eng A 745:369–378

Haghdadi N, Laleh M, Kosari A, Moayed MH, Cizek P, Hodgson PD, Beladi H (2019) The effect of phase transformation route on the intergranular corrosion susceptibility of 2205 duplex stainless steel. Mater. Let. 238:26–30

Haghdadi N, Cizek P, Beladi H, Hodgson PD (2017) Dynamic restoration processes in a 23Cr-6Ni-3Mo duplex stainless steel: Effect of austenite morphology and interface characteristics. Metal. Mater. Trans. A 48:4803–4820

Pinol-Juez A, Iza-Mendia A, Gutierrez I (2000) δ/γ interface boundary sliding as a mechanism for strain accommodation during hot deformation in a duplex stainless steel. Metal Mater Trans A 31(6):1671–1677

Qiu D, Zhan W-Z (2007) A TEM study of the crystallography of austenite precipitates in a duplex stainless steel. Acta Mater 55:6754–6764

Jiao H, Aindow M, Pond RC (2003) Precipitate orientation relationships and interfacial structures in duplex stainless steel Zeron-100. Philos. Mag. 83:1867–1887

Ameyama K, Weatherly GC, Aust KT (1992) A study of grain boundary nucleated widmanstätten precipitates in a two-phase stainless steel. Acta Metal. Mater. 40:1835–1846

Rohrer GS, Saylor DM, El Dasher B, Adams BL, Rollett AD, Wynblatt P (2004) The distribution of internal interfaces in polycrystals. Z Metallkd 95:197–214

Haghdadi N, Cizek P, Beladi H, Hodgson PD (2017) A novel high-strain-rate ferrite dynamic softening mechanism facilitated by the interphase in the austenite/ferrite microstructure. Acta Mater 126:44–57

Wright SI, Larsen RJ (2002) Extracting twins from orientation imaging microscopy scan data. J. Micros. 205:245–252

Raabe D, Ylitalo M (1996) Experimental investigation of the transformation texture in hot rolled ferritic stainless steel using single orientation determination. Metal. Mater. Trans. 27:49–57

Kang JY, Bacroix B, Réglé H, Oh KH, Lee HC (2007) Effect of deformation mode and grain orientation on misorientation development in a body-centered cubic steel. Acta Mater 55:4935–4946

Kurdjumov G, Sachs G (1930) Over the mechanisms of steel hardening. Z. Phys. 64:325–343

Nishiyama Z (1934–1935) X-ray investigation of the mechanism of the transformation from face centered cubic lattice to body centered cubic. Sci Rep Res Inst Tohoku Univ. 23:637–638

Greninger AB, Troiano AR (1949) The mechanism of martensite formation. JSME Trans. 185:590–598

Pitsch W (1962) Der orientierung szusammenhang zwischen zementit und austenite. Acta Metall 10:897–900

Bain EC (1924) The nature of martensite. Trans. AIME 70:25–47

Weatherly GC, Zhang W-Z (1994) The invariant line and precipitate morphology in Fcc-Bcc systems. Metal. Mater. Trans. A 25:1865–1874

Haghdadi N, Cizek P, Hodgson PD, Tari V, Rohrer GS, Beladi H (2018) Five-parameter crystallographic characteristics of the interfaces formed during ferrite to austenite transformation in a duplex stainless steel. Phil Mag 98:1284–1306

Beladi H, Nuhfer NT, Rohrer GS (2014) The five-parameter grain boundary character and energy distributions of a fully austenitic high-manganese steel using three dimensional data. Acta Mater 70:281–289

Rohrer GS, Randle V, Kim CS, Hu Y (2006) Changes in the five-parameter grain boundary character distribution in α-brass brought about by iterative thermomechanical processing. Acta Mater 54:4489–4502

Li J, Dillon SJ, Rohrer GS (2009) Relative grain boundary area and energy distributions in nickel. Acta Mater 57:4304–4311

Randle V, Rohrer GS, Miller HM, Coleman M, Owen GT (2008) Five-parameter grain boundary distribution of commercially grain boundary engineered nickel and copper. Acta Mater 56:2363–2373

He Y, Godet S, Jonas JJ (2006) Observations of the Gibeon meteorite and the inverse Greninger–Troiano orientation relationship. J. App. Crystal. 39:72–81

He Y, Godet S, Jacques PJ, Jonas JJ (2006) Crystallographic relations between face-and body-centred cubic crystals formed under near-equilibrium conditions: observations from the Gibeon meteorite. Acta Mater 54:1323–1334

He Y (2005) Grain-scale characterization of FCC/BCC correspondence relations and variant selection, Doctoral Thesis, McGill University, Canada

Williams DB, Carter CB (2009) Transmission Electron Microscopy—a Textbook for Materials Science. Springer, New York

Townsend RD, Kirkaldy JS (1968) Widmanstatten ferrite formation in Fe-C alloys. Trans. ASM 61:605–619

Chen CY, Yen HW, Yang JR (2007) Sympathetic nucleation of austenite in a Fe–22Cr–5Ni duplex stainless steel. Scripta Mater 56:673–676

Badji R, Bacroix B, Bouabdallah M (2011) Texture, Microstructure and anisotropic properties in annealed 2205 duplex stainless steel welds. Mater. Charac. 62:833–843

Hutchinson WB, Ryde L, Bate PS (2005) Transformation textures in steels. Mater Sci Forum 495:1141–1150

Zaid M, Bhattacharjee PP (2014) Electron backscatter diffraction study of deformation and recrystallization textures of individual phases in a cross-rolled duplex steel. Mater. Charac. 96:263–272

Muthupandi V, Srinivasan PB, Seshadri SK, Sundaresan S (2003) Effect of weld metal chemistry and heat input on the structure and properties of duplex stainless steel welds. Mater Sci Eng A 358:9–16

Lischewski I, Gottstein G (2005) Orientation relationship during partial α-γ-phase transformation in microalloyed steels. Mater Sci Forum 495–497:447–452

Brückner G, Gottstein G (2001) Transformation textures during diffusional α → γ → α phase transformations in ferritic steels. ISIJ Int 41:468–477

Christian JW (1994) Crystallographic theories, interface structures, and transformation mechanisms. Metal. Mater. Trans. A 25:1821–1839

Ohmori Y, Nakai K, Ohtsubo H, Isshiki Y (1995) Mechanism of widmanstätten austenite formation in a δ/γ duplex phase stainless steel. ISIJ Int 35:969–975

Adachi Y, Hakata K, Tsuzaki K (2005) Crystallographic analysis of grain boundary Bcc-precipitates in a Ni–Cr alloy by FESEM/EBSD and TEM/Kikuchi line methods. Mater. Sci. Eng. 412:252–263

Kim DW, Qin RS, Bhadeshia HKDH (2009) Transformation texture of allotriomorphic ferrite in steel. Mater Sci Technol 25:892–895

King AD, Bell T (1975) Crystallography of grain boundary proeutectoid ferrite. Metall Trans A 6:1429–1491

Ramirez AJ, Lippold JC, Brandi SD (2003) The relationship between chromium nitride and secondary austenite precipitation in duplex stainless steels. Metal. Mater. Trans. A 34:1575–1597

Karlsson L, Börjesson J (2014) Orientation relationships of intragranular austenite in duplex stainless steel weld metals. Sci. Technol. Weld. Join. 19:318–323

Porter DA, Easterling KE (1992) Phase Transformation in Materials. Chapman & Hall, Boundary Row, London

Gotoh Y, Uwaha M (1987) Geometrical Interpretation of the Interfacial Energy between bcc and fcc lattices and preferred orientation relationship of the epitaxy. Jap. J. App. Phys. 26:17–20

Nagano T, Enomoto M (2006) Calculation of the interfacial energies between α and γ iron and equilibrium particle shape. Met. Mater. Trans. A 37:929–937

Mackenzie JK, Moore AJW, Nicholas JF (1962) Bonds broken at atomically flat crystal surfaces-I: face-centred and body-centred cubic crystals. J. Phys. Chem. Solid. 23:185–196

Fullman RL, Fisher JC (1951) Formation of annealing twins during grain growth. J Appl Phys 22:1350–1355

Lin B, Jin Y, Hefferan CM, Li SF, Lind J, Suter RM, Bernacki M, Bozzolo N, Rollett AD, Rohrer GS (2015) Observation of annealing twin nucleation at triple lines in nickel during grain growth. Acta Mater 99:63–68

Nolze G (2008) Irrational orientation relationship derived from rational orientation relationships using EBSD data. Crys. Res. Technol. J. Exp. Ind. Crystal. 43:61–73

Menon ESK, Aaronson HI (1987) Overview no 57: morphology, crystallography and kinetics of sympathetic nucleation. Acta Metal 35:549–563

Phelan D, Stanford N, Dippenaar R (2005) Widmanstätten ferrite nucleation in a low Carbon alloy. Mater Sci Eng A 407:127–134

Aaronson HI, Russell KC (1983) In: Aaronson HI, Laughlin DE, Sekerka RF, Wayman CM (eds) Proceedings of an international conference on solid-solid phase transformations. TMS-AIME, Warrendale, PA, (1983)

Russell KC, Barnett DM, Altstetter CJ, Aaronson HI, Lee JK (1977) Strain energy interactions, the T0 concept and sympathetic nucleation. Scr Metall 11:485–490

Acknowledgements

The present work was carried out with the support of the Deakin Advanced Characterisation Facility. NH sincerely acknowledges the financial support by the government of Australian state of Victoria and VESKI through the Victoria Fellowship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Haghdadi, N., Cizek, P., Hodgson, P.D. et al. New insights into the interface characteristics of a duplex stainless steel subjected to accelerated ferrite-to-austenite transformation. J Mater Sci 55, 5322–5339 (2020). https://doi.org/10.1007/s10853-020-04358-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04358-3