Abstract

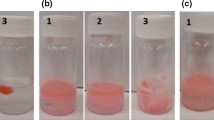

Porous hydrogels with controlled morphology were successfully prepared from polymerizing soy-protein-isolate (SPI)-stabilized high internal phase emulsions (HIPEs). The ability of SPI to act as a surfactant in an oil-in-water HIPE containing acrylic acid or acrylamide monomer was investigated. The void and window sizes in the polyHIPEs were tailored by adjusting SPI and/or monomer concentration. Ultrasonication treatment was applied to vary the physical properties of the SPI. Although this treatment weakens the emulsifying efficiency of SPI, the HIPEs were stable enough to create polyHIPEs with larger pores and windows than polyHIPEs from untreated counterparts. The formation of polyHIPEs with interconnected, open-cell morphologies indicated that SPI is not a typical Pickering emulsifier. The performance of the hydrogels to capture heavy metal (e.g. lead (II)) ions was also explored. The highly interconnected polyHIPE structure with large voids revealed an enhanced absorption behavior compared with non-porous hydrogels.

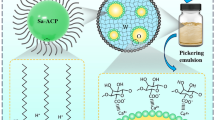

Graphic abstract

Similar content being viewed by others

References

Li P, Jin Z, Peng L et al (2018) Stretchable all-gel-state fiber-shaped supercapacitors enabled by macromolecularly interconnected 3D graphene/nanostructured conductive polymer hydrogels. Adv Mater 30:1800124

Yang C, Wang W, Yao C et al (2015) Hydrogel walkers with electro-driven motility for cargo transport. Sci Rep 5:13622

Lee KY, Mooney DJ (2001) Hydrogels for tissue engineering. Chem Rev 101:1869–1880

Cheng C, Liu Z, Li X et al (2014) Graphene oxide interpenetrated polymeric composite hydrogels as highly effective adsorbents for water treatment. RSC Adv 4:42346–42357

Gong JP (2006) Friction and lubrication of hydrogels—its richness and complexity. Soft Matter 2:544–552

Li J, Mooney DJ (2016) Designing hydrogels for controlled drug delivery. Nat Rev Mater 1:16071

Ma J, Yang M, Yu F, Zheng J (2015) Water-enhanced removal of ciprofloxacin from water by porous graphene hydrogel. Sci Rep 5:13578

Zhou G, Luo J, Liu C et al (2018) Efficient heavy metal removal from industrial melting effluent using fixed-bed process based on porous hydrogel adsorbents. Water Res 131:246–254

Barrow M, Zhang H (2013) Aligned porous stimuli-responsive hydrogels via directional freezing and frozen UV initiated polymerization. Soft Matter 9:2723–2729

Xie X, Hu K, Fang D et al (2015) Graphene and hydroxyapatite self-assemble into homogeneous, free standing nanocomposite hydrogels for bone tissue engineering. Nanoscale 7:7992–8002

Liyanage W, Brennessel WW, Nilsson BL (2015) Spontaneous transition of self-assembled hydrogel fibrils into crystalline microtubes enables a rational strategy to stabilize the hydrogel state. Langmuir 31:9933–9942

Silverstein MS (2017) Emulsion-templated polymers: contemporary contemplations. Polymer (Guildf) 126:261–282

Liu G, Liu Z, Li N et al (2014) Hairy polyelectrolyte brushes-grafted thermosensitive microgels as artificial synovial fluid for simultaneous biomimetic lubrication and arthritis treatment. ACS Appl Mater Interfaces 6:20452–20463

Kovačič S, Drašinac N, Pintar A, Žagar E (2018) Highly porous cationic polyelectrolytes via oil-in-water concentrated emulsions: synthesis and adsorption kinetic study. Langmuir 34:10353–10362

Zhang T, Silverstein MS (2019) Robust, highly porous hydrogels templated within emulsions stabilized using a reactive, crosslinking triblock copolymer. Polymer (Guildf) 168:146–154

Jurjevec S, Žagar E, Kovačič S (2020) Functional macroporous amphoteric polyelectrolyte monoliths with tunable structures and properties through emulsion-templated synthesis. J Colloid Interface Sci

Lissant KJ (1966) The geometry of high-internal-phase-ratio emulsions. J Colloid Interface Sci 22:462–468

Silverstein MS (2014) PolyHIPEs: recent advances in emulsion-templated porous polymers. Prog Polym Sci 39:199–234

Ikem VO, Menner A, Horozov TS, Bismarck A (2010) Highly permeable macroporous polymers synthesized from pickering medium and high internal phase emulsion templates. Adv Mater 22:3588–3592

Ikem VO, Menner A, Bismarck A (2010) High-porosity macroporous polymers synthesized from titania-particle-stabilized medium and high internal phase emulsions. Langmuir 26:8836–8841

Zhang S, Xu J, Hu J et al (2017) Interfacial growth of TiO2-rGO composite by pickering emulsion for photocatalytic degradation. Langmuir 33:5015–5024

Zheng Z, Zheng X, Wang H, Du Q (2013) Macroporous graphene oxide–polymer composite prepared through Pickering high internal phase emulsions. ACS Appl Mater Interfaces 5:7974–7982

Chen Y, Wang Y, Shi X et al (2017) Hierarchical and reversible assembly of graphene oxide/polyvinyl alcohol hybrid stabilized Pickering emulsions and their templating for macroporous composite hydrogels. Carbon N Y 111:38–47

Menner A, Verdejo R, Shaffer M, Bismarck A (2007) Particle-stabilized surfactant-free medium internal phase emulsions as templates for porous nanocomposite materials: poly-pickering-foams. Langmuir 23:2398–2403

Kimmins SD, Cameron NR (2011) Functional porous polymers by emulsion templating: recent advances. Adv Funct Mater 21:211–225

Sun G, Li Z, Ngai T (2010) Inversion of particle-stabilized emulsions to form high-internal-phase emulsions. Angew Chemie Int Ed 49:2163–2166

Yan H, Chen X, Song H et al (2017) Synthesis of bacterial cellulose and bacterial cellulose nanocrystals for their applications in the stabilization of olive oil pickering emulsion. Food Hydrocoll 72:127–135

Yan H, Chen X, Feng M et al (2019) Entrapment of bacterial cellulose nanocrystals stabilized Pickering emulsions droplets in alginate beads for hydrophobic drug delivery. Colloids Surf B Biointerfaces 177:112–120

Capron I, Cathala B (2013) Surfactant-free high internal phase emulsions stabilized by cellulose nanocrystals. Biomacromol 14:291–296

Li Z, Xiao M, Wang J, Ngai T (2013) Pure protein scaffolds from pickering high internal phase emulsion template. Macromol Rapid Commun 34:169–174

Liu W, Gao H, McClements DJ et al (2019) Stability, rheology, and β-carotene bioaccessibility of high internal phase emulsion gels. Food Hydrocoll 88:210–217

Ozturk B, McClements DJ (2016) Progress in natural emulsifiers for utilization in food emulsions. Curr Opin Food Sci 7:1–6

Molina E, Papadopoulou A, Ledward DA (2001) Emulsifying properties of high pressure treated soy protein isolate and 7S and 11S globulins. Food Hydrocoll 15:263–269

Nishinari K, Fang Y, Guo S, Phillips GO (2014) Soy proteins: a review on composition, aggregation and emulsification. Food Hydrocoll 39:301–318

Kalashnikova I, Bizot H, Bertoncini P et al (2013) Cellulosic nanorods of various aspect ratios for oil in water Pickering emulsions. Soft Matter 9:952–959

Xu Y-T, Liu T-X, Tang C-H (2019) Novel pickering high internal phase emulsion gels stabilized solely by soy β-conglycinin. Food Hydrocoll 88:21–30

Liu S, Jin M, Chen Y et al (2017) High internal phase emulsions stabilised by supramolecular cellulose nanocrystals and their application as cell-adhesive macroporous hydrogel monoliths. J Mater Chem B 5:2671–2678

Tan H, Tu Z, Jia H et al (2018) Hierarchical porous protein scaffold templated from high internal phase emulsion costabilized by gelatin and gelatin nanoparticles. Langmuir 34:4820–4829

Wang C, Johnson LA (2001) Functional properties of hydrothermally cooked soy protein products. J Am Oil Chem Soc 78:189–195

Peng IC, Quass DW, Dayton WR, Allen CE (1984) The physicochemical and functional properties of soybean 11S globulin—a review. Cereal Chem 61:480–490

Aoki H, Taneyama O, Inami M (1980) Emulsifying properties of soy protein: characteristics of 7S and IIS proteins. J Food Sci 45:534–538

Tang C-H, Liu F (2013) Cold, gel-like soy protein emulsions by microfluidization: emulsion characteristics, rheological and microstructural properties, and gelling mechanism. Food Hydrocoll 30:61–72

Cao N, Fu Y, He J (2007) Preparation and physical properties of soy protein isolate and gelatin composite films. Food Hydrocoll 21:1153–1162

de Souza PaglariniC, de Figueiredo FurtadoG, Biachi JP et al (2018) Functional emulsion gels with potential application in meat products. J Food Eng 222:29–37

Deng X, Chen Z, Huang Q, et al (2014) Spray-drying microencapsulation of β-carotene by soy protein isolate and/or OSA-modified starch. J Appl Polym Sci 131:40399

Hu H, Wu J, Li-Chan ECY et al (2013) Effects of ultrasound on structural and physical properties of soy protein isolate (SPI) dispersions. Food Hydrocoll 30:647–655

Karki B, Lamsal BP, Grewell D et al (2009) Functional properties of soy protein isolates produced from ultrasonicated defatted soy flakes. J Am Oil Chem Soc 86:1021–1028

Corredig M (2009) Heat-induced changes in oil-in-water emulsions stabilized with soy protein isolate. Food Hydrocoll 23:2141–2148

May GJ, Davidson A, Monahov B (2018) Lead batteries for utility energy storage: a review. J Energy Storage 15:145–157

Bellinger DC (2008) Lead neurotoxicity and socioeconomic status: conceptual and analytical issues. Neurotoxicology 29:828–832

Smith PK, Il KrohnR, Hermanson GT et al (1985) Measurement of protein using bicinchoninic acid. Anal Biochem 150:76–85

Zhao B, Gedler G, Manas-Zloczower I et al (2020) Fluid transport in open-cell polymeric foams: effect of morphology and surface wettability. SN Appl Sci 2:1–10

Lee H, Yildiz G, Dos Santos LC et al (2016) Soy protein nano-aggregates with improved functional properties prepared by sequential pH treatment and ultrasonication. Food Hydrocoll 55:200–209

Viet MH, Derreumaux P, Nguyen PH (2016) Nonequilibrium all-atom molecular dynamics simulation of the bubble cavitation and application to dissociate amyloid fibrils. J Chem Phys 145:174113

Yang F, Liu X, Ren X et al (2018) Swirling cavitation improves the emulsifying properties of commercial soy protein isolate. Ultrason Sonochem 42:471–481

Gong K-J, Shi A-M, Liu H-Z et al (2016) Emulsifying properties and structure changes of spray and freeze-dried peanut protein isolate. J Food Eng 170:33–40

Chevrel M-C, Brun N, Hoppe S et al (2014) In situ monitoring of acrylic acid polymerization in aqueous solution using rheo-Raman technique. Experimental investigation and theoretical modelling. Chem Eng Sci 106:242–252

Kabanov VA, Topchiev DA, Karaputadze TM, Mkrtchian LA (1975) Kinetics and mechanism of radical polymerization of weak unsaturated acids in aqueous solutions. Eur Polym J 11:153–159

Cutié SS, Smith PB, Henton DE et al (1997) Acrylic acid polymerization kinetics. J Polym Sci, Part B: Polym Phys 35:2029–2047

Elliott JE, Macdonald M, Nie J, Bowman CN (2004) Structure and swelling of poly (acrylic acid) hydrogels: effect of pH, ionic strength, and dilution on the crosslinked polymer structure. Polymer (Guildf) 45:1503–1510

Yildiz G, Andrade J, Engeseth NE, Feng H (2017) Functionalizing soy protein nano-aggregates with pH-shifting and mano-thermo-sonication. J Colloid Interface Sci 505:836–846

Jiang J, Chen J, Xiong YL (2009) Structural and emulsifying properties of soy protein isolate subjected to acid and alkaline pH-shifting processes. J Agric Food Chem 57:7576–7583

Mittal H, Maity A, Sinha Ray S (2015) The adsorption of Pb2+ and Cu2+ onto gum ghatti-grafted poly (acrylamide-co-acrylonitrile) biodegradable hydrogel: isotherms and kinetic models. J Phys Chem B 119:2026–2039

Zhou C, Wu Q (2011) A novel polyacrylamide nanocomposite hydrogel reinforced with natural chitosan nanofibers. Colloids Surfaces B Biointerfaces 84:155–162

Kataruka A, Hutchens SB (2019) PDMS polymerized high internal phase emulsions (polyHIPEs) with closed-cell, aqueous-filled microcavities. Soft Matter 15:9665–9675

Zhu W, Zhu Y, Zhou C, Zhang S (2019) Pickering emulsion-templated polymers: insights into the relationship between surfactant and interconnecting pores. RSC Adv 9:18909–18916

Chu L, Liu C, Zhou G et al (2015) A double network gel as low cost and easy recycle adsorbent: highly efficient removal of Cd (II) and Pb (II) pollutants from wastewater. J Hazard Mater 300:153–160

Liu D, Li Z, Li W et al (2013) Adsorption behavior of heavy metal ions from aqueous solution by soy protein hollow microspheres. Ind Eng Chem Res 52:11036–11044

Lagergren S (1898) Zur theorie der sogenannten adsorption geloster stoffe. Kungl Svenska Vetenskapsakad Handl 24(4):1–39

Ho Y-S (2006) Review of second-order models for adsorption systems. J Hazard Mater 136:681–689

Chien SH, Clayton WR (1980) Application of Elovich equation to the kinetics of phosphate release and sorption in soils. Soil Sci Soc Am J 44:265–268

Langmuir I (1916) The constitution and fundamental properties of solids and liquids. Part I. Solids. J Am Chem Soc 38:2221–2295

Liu Y, Wang W, Wang A (2010) Adsorption of lead ions from aqueous solution by using carboxymethyl cellulose-g-poly (acrylic acid)/attapulgite hydrogel composites. Desalination 259:258–264

Lam S, Velikov KP, Velev OD (2014) Pickering stabilization of foams and emulsions with particles of biological origin. Curr Opin Colloid Interface Sci 19:490–500

Liu F, Tang C-H (2013) Soy protein nanoparticle aggregates as Pickering stabilizers for oil-in-water emulsions. J Agric Food Chem 61:8888–8898

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Catalin Croitoru.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Gong, X., Rohm, K., Su, Z. et al. Porous hydrogels templated from soy-protein-stabilized high internal phase emulsions. J Mater Sci 55, 17284–17301 (2020). https://doi.org/10.1007/s10853-020-05261-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05261-7