Abstract

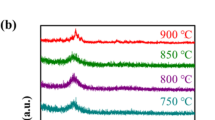

YBa2Cu3O7-x precursor film prepared by metal-organic deposition method was sintered and oxygenated at 800 °C and 450 °C, respectively. The dynamic in situ resistance data in the sintering process of film was recorded, and the phase composition and transformation of YBa2Cu3O7-x precursor film in treating stages were discussed. In the heating stage of 710–795 °C, the film resistance increased with temperature, which may be explained by that the grains grew larger and internal gaps formed. The tetragonal YBa2Cu3O7-x shows good conductivity at 77–270 K. When temperature ranged from 450 to 800 °C, the tetragonal YBa2Cu3O7-x became very sensitive to oxygen, and the film resistance dropped sharply once oxygen entered. The scanning electron microscope images showed that the oxygen infiltration at 800 °C was more contributing to grain fusion and connectivity. The X-ray diffraction patterns of samples with oxygen infiltration at 800 °C exhibited that the phase transformation to YBa2Cu3O7-x was more fully. The R-T curve and I-V curve were measured by the four-probe method, the transition temperature Tc are 89.8 K and 93.4 K, and the critical current densities Jc are 0.32MA/cm2 and 0.89MA/cm2 (77 K, 0 T) respectively. Tc and Jc curves illustrated that the samples had higher superconductivity, compared with those experienced oxygen infiltrations at 450 °C.

Similar content being viewed by others

References

Gupta, A., Jagannathan, R., Cooper, E.I., Giess, E.A., Landman, J.I.: Superconducting oxide films with high transition temperature prepared from metal trifluoroacetate precursors. Appl. Phys. Lett. 52(24), 2077–2079 (1988). https://doi.org/10.1063/1.99752

Teranishi, R., Fuji, H., Honjo, T., Nakamura, Y., Izumi, T., Shiohara, Y., Shibata, J., Yamamoto, T., Ikuhara, Y., Yoshimura, M.: Growth mechanism of Y123 film by MOD-TFA process. Physica C: Superconductivity. 378-381, 1033–1038 (2002). https://doi.org/10.1016/S0921-4534(02)01573-3

Dong, Z.B., Gu, H.W., Zhang, H.L., Shang, H.J., Huang, D.X., Xu, W.J., Zhang, H., Ding, F.Z.: Heat treatment design of precursor solutions with different fluorine contents for YBa2Cu3O7−x films through the sol-gel approach. J. Sol-Gel Sci. Technol. 90, 263–270 (2019). https://doi.org/10.1007/s10971-019-04940-5

Ono, T., Matsumoto, K., Osamura, K., Hirabayashi, I.: Microstructural observation of YBa2Cu3O7−x thin films prepared by TFA-MOD method. Physica C: Superconductivity. 392-396, 917–921 (2003). https://doi.org/10.1016/S0921-4534(03)01190-0

Li M.Y.,·Fang Q., Hu X. F., Liu Z.Y., Guo Y. Q.,·Lu Y. M., Bai C.Y., Cai C.B.. Microstructures property and improved Jc of Eu-doped YBa2Cu3.6O7−δ thin films by trifluoroacetate metal organic deposition process. J. Supercond. Nov. Magn. 30: 1137–1143 (2017). https://doi.org/10.1007/s10948-016-3891-6

Li, C.Y., Suo, H.L., Ye, S., Liu, M., Ma, L., Tian, M., Wang, Y.: Effect of Yb substitution on microstructure and superconducting properties of Y1-xYbxBa2Cu3O7-δ films. J. Supercond. Nov. Magn. 31, 2705–2710 (2018). https://doi.org/10.1007/s10948-017-4485-7

Wang, Y.H., Ding, F.Z., Gu, H.W., Zhang, H.L., Dong, Z.B.: Microstructure and superconducting properties of (BaTiO3, Y2O3)-doped YBCO films under different firing temperatures. Rare Metals. 36(1), 37–41 (2017). https://doi.org/10.1007/s12598-015-0606-2

Chen, H., Xavier, P., Xavier, O., Han, Z.H.: Study on the growth rate of YBCO films prepared by TFA-MOD. CRYOGENICS AND SUPERCONDUCTIVITY. 38(8), 28–31 (2010). https://doi.org/10.16711/j.1001-7100.2010.08.008

Cui, X.M., Tao, B.W., Xiong, J., Liu, X.Z., Zhu, J., Li, Y.R.: Effect of annealing time on the structure and properties of YBCO films by the TFA–MOD method. Physica C: Superconductivity. 432(3–4), 147–152 (2005). https://doi.org/10.1016/j.physc.2005.08.001

Wang, W.T., Zhao, Y., Yang, X.F., Wang, W., Pu, M.H.: Influence of pyrolysis atmosphere on YBa2Cu3O7−x superconducting film preparation by non-fluorine chemical solution deposition method. Materials Letters. 68, 429–431 (2012). https://doi.org/10.1016/j.matlet.2011.11.018

Dou, W.Z., Liu, Z.Y., Peng, C.H., Bai, C.Y., Lu, Y.M., Guo, Y.Q., Cail, C.B.: Phase transition during heat treatment of precursor before YBa2Cu3O7−δ nucleation in TFA-MOD method. J. Supercond. Nov. Magn. 29, 1997–2001 (2016). https://doi.org/10.1007/s10948-016-3514-2

Chen, Y.Q., Yin, X.R., Feng, Y., Bian, W.B., Li, M.J., Niu, J.F.: High-efficiency preparation of high-quality YBCO superconducting films using an ultralow-fluorine sol–gel method. J. Sol-Gel Sci. Technol. 74, 249–255 (2015). https://doi.org/10.1007/s10971-014-3606-z

Farshad, F.A., Mehdi, H., Mehdi, F.: Optimization of a/b-axis regions of YBCO thin film for sensor applications. Proc. Natl. Acad. Sci., India, Sect. A: Phys. Sci. 88(4), 625–628 (2018). https://doi.org/10.1007/s40010-017-0392-3

Wang, S.S., Zhang, Z.L., Li, M.H., Li, M.J., Gao, L.K., Wei, B., Cao, B.S.: Study of precursor-solution purity for high-quality yttrium–barium–copper-oxide superconducting thin film. J. Sol-Gel Sci. Technol. 86, 690–698 (2018). https://doi.org/10.1007/s10971-018-4624-z

Shin, G.M., Ko, K.P., Song, K.J., Moon, S.H., Yoo, S.I.: High-IC YBCO films fabricated by the MOD process. Physica C Superconductivity. 468, 1567–1570 (2008). https://doi.org/10.1016/j.physc.2008.05.068

Zhao, X.M., Wang, T.L., Hong, S.C., Sun, D.L., Wang, N., Chae, G.S., Qi, Y.: Superconducting properties and non-isothermal crystallization kinetics of a Bi2Sr2CaCu2O8+d (Bi2212) superconductor prepared by the Pechini sol–gel method. RSC Adv. 9, 35280–35288 (2019). https://doi.org/10.1039/C9RA07586K

Jorgensen, J.D., Hinks, D.G., Chmaissem, O., Argyriou, D.N., Mitchell, J.F., Dabrowski, B.: Structural features that optimize high temperature superconductivity. Phys. Rev. B. 41, 1–15 (1990). https://doi.org/10.1007/BFb0102015

Tchabukiani, T., Daraselia, D., Japaridze, D., Jibuti, Z., Shengelaya, A.: Study of superconductivity in YBa2Cu3O7-x/SrTiO3 composites. J. Supercond. Nov. Magn. 32(10), 3121–3124 (2019). https://doi.org/10.1007/s10948-019-5085-5

Funding

The project was funded by the National Training Program of Innovation and Entrepreneurship for Undergraduates (201910145043), China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Y., Gong, Y., Tao, J. et al. Study on Dynamic Change of In Situ Resistance During Sintering Process of YBCO Precursor Film. J Supercond Nov Magn 33, 1987–1993 (2020). https://doi.org/10.1007/s10948-020-05462-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-020-05462-w