Abstract

A silica-supported bis(n-butylcyclopentadienyl) zirconium dichloride [(nBuCp)2ZrCl2] catalyst was synthesized. This was used to prepare an ethylene homopolymer and an ethylene–1-hexene copolymer. The active center multiplicity of this catalyst was modeled by deconvoluting the copolymer molecular mass distribution and chemical composition distribution. Five different active site types were predicted, which matched the successive self-nucleation and annealing temperature peaks. The thermo-oxidative melt stability, with and without Irganox 1010 and Irgafos 168, of the above polyethylenes was investigated using nonisothermal differential scanning calorimetric (DSC) experiments at 150 °C. This is a temperature that ensures complete melting of the samples and avoids the diffusivity of oxygen to interfere into polyethylene crystallinity and its thermo-oxidative melt degradation. The oxidation parameters such as onset oxidation temperature, induction period, protection factor, and S-factor were determined by combining theoretical modeling with the DSC experiments. Subsequently, these findings were discussed considering catalyst active center multiplicity and polymer microstructure, particularly average ethylene sequence length. Several insightful results, which have not been reported earlier in the literature, were obtained. The antioxidant effect, for each polymer, varied as (Irganox + Irgafos) ≈ Irganox > Irgafos > Neat polymer. The as-synthesized homopolymer turned out to be almost twice as stable as the corresponding copolymer. The antioxidant(s) in the copolymer showed higher antioxidant effectiveness (AEX) than those in the homopolymer. Irganox exhibited more AEX than Irgafos. To the best of our knowledge, such findings have not been reported earlier in the literature. However, mixed with Irganox or Irgafos, their melt oxidation stability was comparable. The homopolymer, as per the calculated S-factor, showed Irganox–Irgafos synergistic effect five times that of the copolymer. This illustrates how the transition in backbone structure, from exceedingly high to low ethylene sequence length, influences antioxidant synergistic performance. Finally, this study shows a DSC-aided approach that can elucidate the effect of polyethylene structural backbone on its thermo-oxidative melt degradation as well as antioxidant synergism in a facile fashion.

Similar content being viewed by others

References

Severn JR, Chadwick JC. Tailor-made polymers: via immobilization of alpha-olefin polymerization catalysts. Weinheim: Wiley-VCH Verlag GmbH and Co. KGaA; 2008.

Zhuravlev LT. Surface chemistry of silica. In: Bergna HE, Roberts WO, editors. Colloidal silica: fundamentals and applications. New York: CRC Press, Taylor and Francis Group; 2005.

Gajan D, Copéret C. Silica-supported single-site catalysts: to be or not to be? A conjecture on silica surfaces. N J Chem. 2011;352:2403–8.

Chen EYX, Marks TJ. Cocatalysts for metal-catalyzed olefin polymerization: activators, activation processes, and structure–activity relationships. Chem Rev. 2000;100:1391–434.

Zurek EA. Theoretical Investigation of the structure and function of MAO. MS Thesis, University of Calgary, Calgary, 2002.

Negureanu L, Hall RW, Butler LG, Simeral LA. Methylaluminoxane (MAO) polymerization mechanism and kinetic model from ab initio molecular dynamics and electronic structure calculations. J Am Chem Soc. 2006;128:16816–26.

Linnolahti M, Severn JR, Pakkanen TA. Formation of nanotubular methylaluminoxanes and the nature of the active species in single-site α-olefin polymerization catalysis. Angew Chem Int Ed. 2008;47:9279–83.

Kim JD, Soares JBP. Copolymerizations of ethylene with 1-decene over various ansa–metallocene complexes combined with Al(i-Bu)3/[CPh3][B(C6F5)] cocatalyst. Macromol Rapid Commun. 1999;20:347–50.

Moreno J, van Grieken R, Carrero A, Paredes B. Ethylene polymerization by metallocene catalysts supported over siliceous materials with bimodal pore size distribution. Macromol Symp. 2011;302:198–207.

Paredes B, Soares JBP, Grieken RV, Carrero A, Suarez I. Characterization of ethylene–1-hexene copolymers made with supported metallocene catalysts: influence of support type. Macromol Symp. 2007;257:103–11.

Paredes B, Grieken RV, Carrero A, Suarez I, Soares JBP. Ethylene/1-hexene copolymers produced with MAO/(nBuCp)2ZrCl2 supported on SBA-15 materials with different pore sizes. Macromol Chem Phys. 2011;212:1590–9.

Hung J, Cole AP, Waymouth RM. Control of sequence distribution of ethylene copolymers: influence of comonomer sequence on the melting behavior of ethylene copolymers. Macromolecules. 2003;36:2454–63.

Koenig JL. Chemical microstructure of polymer chains. New York: Wiley; 1980.

Chaichana E, Khaubunsongserm S, Praserthdam P, Jongsomjit B. Ethylene–hexene copolymer derived from [t-butylfluorenylsilyl-amido] dimethyl titanium complex. Exp Polym Lett. 2010;4:94–100.

Hussain I, Atiqullah M, Fazal A, Alam K, Hossaen A. Effect of selected residual Ziegler–Natta and metallocene catalysts on the UV-induced degradation of unstabilized ethylene homopolymer films. Polym Degrad Stab. 2010;95:2289–99.

Atiqullah M, Winston MS, Bercaw JE, Hussain I, Fazal A, Al-Harthi MA, Emwas AHM, Khan MJ, Hossaen A. Effects of a vanadium post-metallocene catalyst-induced polymer backbone inhomogeneity on UV oxidative degradation of the resulting polyethylene film. Polym Degrad Stab. 2012;97:1164–77.

Atiqullah M, Hossain MM, Rahman SM, Alam K, Al-Muallem HA, Alharbi AF, Hussain I, Hossaen A. Apparent kinetics of nonisothermal high temperature oxidative degradation of ethylene homopolymers: effects of residual catalyst surface chemistry and structure. J Polym Res. 2013;20(56):1–15.

Hansen LD, Eatough DJ, Lewis EA, Bergstrom RG, Degraft-Johnson D, Cassidy-Thompson K. Shelf-life prediction from induction period calorimetric measurements on materials undergoing autocatalytic decomposition. Can J Chem. 1990;68:2111–4.

Šimon P, Kolman Ľ, Niklová I, Schmidt Š. Analysis of the induction period of oxidation of edible oils by differential scanning calorimetry. J Am Oil Chem Soc. 2000;77:639–42.

Šimon P, Kolman Ľ. DSC study of oxidation induction periods. J Therm Anal Calorim. 2001;64:813–20.

Gregorová A, Cibulková Z, Košíková B, Šimon P. Stabilization effect of lignin in polypropylene and recycled polypropylene. Polym Degrad Stab. 2005;89:553–8.

Cibulková Z, Šimon P, Lehocký P, Balko J. Antioxidant activity of p-phenylenediamines studied by DSC. Polym Degrad Stab. 2005;87:479–86.

Cibulková Z, Šimon P, Lehocký P, Balko J. Antioxidant activity of 6PPD derivatives in polyisoprene matrix studied by non-isothermal DSC measurements. J Therm Anal Calorim. 2005;80:357–61.

Cibulková Z, Šimon P, Lehocký P, Kosár K, Uhlár J. DSC study of the influence of p-substituted diphenyl amines on the thermooxidative stability of styrene–butadiene rubber. J Therm Anal Calorim. 2010;101:679–84.

Cibulková Z, Šimon P, Lehocký P, Kosár K, Chochulová A. DSC study of antioxidant activity of selected p-phenylenediamines in styrene–butadiene rubber. J Therm Anal Calorim. 2009;97:535–40.

Cibulková Z, Černá A, Šimon P, Lehocký P, Kosár K, Uhlár J. Stabilization effect of potential antioxidants on the thermooxidative stability of styrene–butadiene rubber. J Therm Anal Calorim. 2011;105:607–13.

Woo L, Khare A, Blom HP, Sandford C, Ding SY. Application of the oxidative induction test to depolymerizing systems. Thermochim Acta. 2001;367:113–8.

Gillen KT, Bernstein R, Derzon DK. Evidence of non-Arrhenius behaviour from laboratory aging and 24-year field aging of polychloroprene rubber materials. Polym Degrad Stab. 2005;87:57–67.

Gillen KT, Bernstein R, Celina M. Non-Arrhenius behavior for oxidative degradation of chlorosulfonated polyethylene materials. Polym Degrad Stab. 2005;87:335–46.

Celina M, Gillen KT, Assink RA. Accelerated aging and lifetime prediction: review of non-Arrhenius behaviour due to two competing processes. Polym Degrad Stab. 2005;90:395–404.

Šimon P, Hynek D, Malíková M, Cibulková Z. Extrapolation of accelerated thermooxidative tests to lower temperatures applying non-Arrhenius temperature functions. J Therm Anal Calorim. 2008;93:817–21.

Šimon P. Single-step kinetics approximation employing non-Arrhenius temperature functions. J Therm Anal Calorim. 2005;79:703–8.

Šimon P. Material stability predictions applying a new non-Arrhenian temperature function. J Therm Anal Calorim. 2009;97:391–6.

Atiqullah M, Hossain MM, Kamal MS, Al-Harthi MA, Hossaen A, Khan MJ, Hussain I. Crystallization kinetics of PE-b-isotactic PMMA diblock copolymer synthesized using SiMe2(Ind)2ZrMe2 and MAO cocatalyst. AIChE J. 2013;59:200–12.

Wood-Adams PM, Dealy JM, DeGroot AW, Redwine OD. Effect of molecular structure on the linear viscoelastic behavior of polyethylene. Macromolecules. 2000;33:7489–99.

Runt JP. Crystallinity determination. In: Mark HF, editor. Encyclopedia of polymer science and engineering. New York: Wiley; 1989. p. 482–7.

Czaja K, Sacher B, Białek M. Studies of intermolecular heterogeneity distribution in ethylene/1-hexene copolymers using DSC method. J Therm Anal Calorim. 2002;67:547–54.

Hsieh ET, Randall JC. Monomer sequence distributions in ethylene–1-hexene copolymers. Macromolecules. 1982;15:1402–6.

Seger MR, Maciel GE. Quantitative 13C NMR analysis of sequence distributions in poly(ethylene-co-1-hexene). Anal Chem. 2004;76:5734–47.

Wigum H, Tangen L, Støvneng JA, Rytter E. Ethene homopolymerization and copolymerization with 1-hexene for all methyl-substituted (R n C5H5−n )2ZrCl2/MAO catalytic systems: effects of split methyl substitution. J Polym Sci A. 2000;38:3161–72.

Blom R, Follestad A, Noel O. Kinetics of chain transfer during ethylene polymerization with chromium oxide/silica catalyst. J Mol Catal. 1994;91:237–49.

Kim I, Ha C-S. Kinetics of homo- and copolymerizations of ethylene by zirconocarborane catalyst cocatalyzed by AlR3 or methyl aluminoxane. Appl Catal A. 2003;251:167–80.

Hoáng EM, Allen NS, Liauw CM, Fontán E, Lafuente P. The thermo-oxidative degradation of metallocene polyethylenes: Part 2: thermal oxidation in the melt state. Polym Degrad Stab. 2006;91:1356–72.

Vosko SH, Wilk L, Nusair M. Accurate spin-dependent electron liquid correlation energies for local spin density calculations: a critical analysis. Can J Phys. 1980;58:1200–11.

Gugumus F. Thermooxidative degradation of polyolefins in the solid state. Part 2: homogeneous and heterogeneous aspects of thermal oxidation. Polym Degrad Stab. 1996;52:145–57.

Simha R, Branson H. Theory of depolymerization of long chain molecules. J Chem Phys. 1944;12:253–67.

Stockmayer WH. Distribution of chain length and compositions in copolymers. J Chem Phys. 1945;13:199–207.

Soares JBP. An overview of important microstructural distributions for polyolefin analysis. Macromol Symp. 2007;257:1–12.

Anantawaraskul S, Bongsontia W, Soares JBP. Simultaneous deconvolution of molecular weight distribution and chemical composition distribution of ethylene/1-olefin copolymers: strategy validation and comparison. Macromol React Eng. 2011;8:549–62.

Ystenes M, Eilertsen JL, Liu J, Matthias OH, Rytter E, Stovneng JA. Experimental and theoretical investigations of the structure of methylaluminoxane (MAO) cocatalysts for olefin polymerization. J Polym Sci A. 2000;38:3106–27.

Talsi EP, Semikolenova NV, Panchenko VN, Sobolev AP, Babushkin DE, Shubin AA, Zakharov VA. The metallocene/methylaluminoxane catalysts formation: EPR spin probe study of Lewis acidic sites of methylaluminoxane. J Mol Catal A. 1999;139:131–7.

Boudene Z, Bruin TD, Toulhoat H, Raybaud P. A QSPR investigation of thermal stability of [Al(CH3)O] n oligomers in methylaluminoxane solution: the identification of a geometry-based description. Organometallics. 2012;31:8312–22.

Allen NS, Edge M, Holdsworth D, Rahman A, Catalina F, Fontan E, Escalona AM, Sibon FF. Ageing and spectroscopic properties of polyethylenes: comparison with metallocene polymer. Polym Degrad Stab. 2000;67:57–67.

Černá A, Cibulková Z, Šimon P, Uhlár J, Lehocký P. DSC study of selected antioxidants and their binary mixtures in styrene–butadiene rubber. Polym Degrad Stab. 2012;97:1724–9.

Pospíšil J. Chemical and photochemical behaviour of phenolic antioxidants in polymer stabilization—a state of the art report, Part I. Polym Degrad Stab. 1993;40:217–32.

Pospíšil J. Chemical and photochemical behaviour of phenolic antioxidants in polymer stabilization: a state of the art report, Part II. Polym Degrad Stab. 1993;39:103–15.

Zweifel H. Stabilization of polymeric materials. Berlin: Springer; 1998.

Kriston I, Orbán-Mester Á, Nagy G, Staniek P, Földes E, Pukánszky B. Melt stabilisation of Phillips type polyethylene, Part II: correlation between additive consumption and polymer properties. Polym Degrad Stab. 2009;94:1448–56.

Allen NS, Edge M. Fundamentals of polymer degradation and stabilization. New York: Elsevier Applied Science; 1992.

Zweifel H, Maier RD, Schiller M. Plastics additives handbook. Muenchen: Hanser Verlag; 2009.

Acknowledgements

The authors acknowledge the financial support provided by King Abdulaziz City for Science and Technology (KACST) via the Science and Technology Unit at King Fahd University of Petroleum and Minerals (KFUPM) through Project Number 08-PET90-4 as part of the National Science and Technology Innovation Plan. The technical assistance provided by the following KFUPM centers—Center of Refining and Petrochemicals (CRP) and Center for Engineering Research at Research Institute, and the Center of Research Excellence in Petroleum Refining and Petrochemicals (CoRE-PRP)—at Dhahran, Saudi Arabia; NMR Core Laboratory, Thuwal, King Abdullah University of Science and Technology (KAUST), Saudi Arabia; the Department of Chemical Engineering at KFUPM and the Department of Chemical Engineering at Kasetsart University, Thailand; and Institute of Physical Chemistry and Chemical Physics, Slovak University of Technology, Slovak Republic is also gratefully acknowledged. Messrs. Anwar Hossaen and Sarath P. Unnikari are appreciated for technical support.

Author information

Authors and Affiliations

Corresponding authors

Appendix: simultaneous MWD and CCD deconvolution model and computational algorithm

Appendix: simultaneous MWD and CCD deconvolution model and computational algorithm

Single-site binary copolymer MWD and CCD

Stockmayer bivariate distributions of chain length CL and composition are assumed to apply to represent, respectively, the mass distributions of kinetic CL l kc and chemical composition F 1 of copolymer backbones synthesized by a given active catalyst site type. F 1 stands for mole fraction of ethylene in the copolymer backbone. Accordingly, the Stockmayer distribution for linear binary copolymer backbones w(l kc, F 1) can be written as follows [46–49]:

where τ is the ratio of the sum of all chain transfer rates to the copolymerization propagation rate. \( \bar{F}_{1} \) is the average mole fraction of monomer 1 in the copolymer. β is given by [48, 49]:

where r 1 and r 2 are the copolymerization reactivity ratios of monomers 1 and 2 (corresponding to the above catalyst active site type), respectively. r 1 r 2 = 1 for random copolymers produced with a typical single-site catalyst. Generally speaking, r 1 r 2 is a kinetic parameter of the Mayo–Lewis copolymerization equation that is used to calculate instantaneous copolymer composition (due to drift in monomer concentration with conversion) and classify copolymerization type.

Equation 10 comprises the CL distribution CLD and CCD components of Stockmayer distribution. The CLD component can be obtained by integrating Eq. 10, that is, w(l kc, F 1) over all chemical compositions, and this is given by Eq. 12 [48, 49]:

Therefore, the Stockmayer binary copolymer CLD equals the most probable Flory–Schulz CLD with PDI M w/M n = 2 for a single active catalyst center type [48, 49].

For linear chains, the parameter τ is the reciprocal of the number average CL l n, that is, \( \tau = \frac{1}{{l_{\text{n}} }}. \) Now, we shall convert Eq. 12 into the MWD analog so that we may use the GPC-generated MWD to deconvolute it, and eventually determine the number of active catalyst site types. This is shown below.

The CLD w(l kc) is related to the corresponding MWD w(MW) through the following expression [48]:

where MW is the instantaneous copolymer molecular mass. \( \frac{\text{dMW}}{{{\text{d}}l_{\text{kc}} }} \) equals the molecular mass mwru of the ru (ethylene) in the polymer. Therefore, Eq. 13 becomes

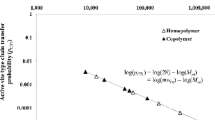

where \( \frac{\tau }{{{\text{mw}}_{\text{ru}} }} = \frac{1}{{l_{\text{n}} \times {\text{mw}}_{\text{ru}} }} = \frac{1}{{M_{\text{n}} }}, \) and M n is the number average molecular mass of the polymer. Now, we shall transform Eq. 14 into the corresponding logarithmic form using the following relation:

Using Eqs. 14 and 15, we can finally write the following expression that directly relates to GPC MWD:

As reported above, the CCD component of Stockmayer distribution can be likewise calculated by integrating Eq. 10 over all CLs. For a given catalyst site type, this is given by [48, 49]

Equation 17 correlates the CCD to instantaneous copolymer composition F 1. However, for copolymer chains made by a given active catalyst site type, the average mole fraction of monomer 1 does not statistically depend on the kinetic CL l kc; long and short chains have the same average chemical composition.

Multi-site binary copolymer MWD and CCD

The copolymer MWD and CCD produced by a multi-site catalyst can be considered to consist of these backbone microstructural properties generated by each catalyst active site type. Therefore, under this situation, the bivariate MWD and CCD can be obtained by superposing the corresponding Stockmayer distributions represented by Eqs. 16 and 17, respectively. Accordingly, we can write the following [48, 49]:

where w i(logMW), w i(F 1), and m i are the MWD, CCD, and mass fraction of copolymer chains produced by catalyst site type i, respectively. w(logMW) and w(F 1) are the corresponding overall distributions.

Combining Eqs. 16 and 18, we can write the multi-site MWD as follows [48, 49]:

Similarly, considering Eqs. 17 and 19, the multi-site CCD can be written as [48, 49]

where \( \beta_{\text{i}} = \bar{F}_{1{\text{i}}} (1 - \bar{F}_{1{\text{i}}} ) \times \sqrt {1 + 4\bar{F}_{1{\text{i}}} (1 - \bar{F}_{1{\text{i}}} )\;(r_{1{\text{i}}} r_{2{\text{i}}} - 1)} , \) and w i(F 1) is the CCD of copolymer chains produced by catalyst site type i. F 1 is the instantaneous mole fraction of monomer 1 in the overall copolymer. \( \bar{F}_{1{\text{i}}} \) is the average mole fraction of monomer 1; r 1i and r 2i are the reactivity ratios of monomers 1 and 2, respectively, where subscript i represents the catalyst site type. Note that \( \sum\nolimits_{i = 1}^{n} {m_{{\text{i}}} = 1} . \)

Computational algorithm for the simultaneous deconvolution of copolymer MWD and CCD

We outline the MWD and CCD deconvolution procedures as follows:

-

(i)

Formulate, using Eqs. 20 and 21, the objective function to be minimized χ 2 as follows [48, 49]:

$$ \begin{aligned} \chi^{2} = \chi_{\text{MWD}}^{2} + \chi_{\text{CCD}}^{2} & = \frac{1}{{m_{\text{MWD}} }}\sum\limits_{j = 1}^{{m_{\text{MWD}} }} {\left[ {w_{\exp } (\log {\text{MW}}) - w_{\bmod } (\log {\text{MW}})} \right]^{2} } \\ & \quad + \frac{1}{{m_{\text{CCD}} }}\sum\limits_{k = 1}^{{m_{\text{CCD}} }} {\left[ {w_{\exp } \left( {F_{1} } \right) - w_{\bmod } \left( {F_{1} } \right)} \right]}^{2} , \\ \end{aligned} $$(22)where \( \chi_{\text{MWD}}^{2} \)and \( \chi_{\text{CCD}}^{2} \) are objective function components for MWD and CCD, respectively. m MWD and m CCD are, respectively, the total MWD and CCD experimental data points considered to minimize Eq. 22. Subscripts exp and mod represent experimental and model-predicted values. Note that Eq. 22 considers the simultaneous deconvolution of MWD and CCD to achieve more consistent results.

-

(ii)

First assume two active site types, that is, n = 2 to deconvolute the GPC MWD and Crystaf CCD. Accordingly, estimate m 1, τ 1, τ 2, β 1, β 2, and \( \bar{F}_{1i} . \) m 2 is excluded from estimation because \( \sum\nolimits_{{\text{i}} = 1}^{n} {m_{{\text{i}}} = 1} . \) For n = 2, m 1, m 2, τ 1, and τ 2 can be initially estimated using the following GPC data—number-, mass-, and z-average molecular masses—and by solving the following equations [49]:

$$ \frac{{M_{\text{n}} }}{{{\text{mw}}_{\text{ru}} }} = \frac{1}{{m_{1} \tau_{1} + m_{2} \tau_{2} }}, $$(23)$$ \frac{{M_{\text{w}} }}{{{\text{mw}}_{\text{ru}} }} = 2\left( {\frac{{m_{1} }}{{\tau_{1} }} + \frac{{m_{2} }}{{\tau_{2} }}} \right), $$(24)$$ \frac{{M_{\text{z}} }}{{{\text{mw}}_{\text{ru}} }} = 3\left( {\frac{{m_{1} }}{{\tau_{1}^{2} }} + \frac{{m_{2} }}{{\tau_{2}^{2} }}} \right)\,\left( {\frac{{m_{1} }}{{\tau_{1} }} + \frac{{m_{2} }}{{\tau_{2} }}} \right)^{ - 1} . $$(25) -

(iii)

For n + 1 (n ≥ 2), site types make the initial guesses for m i and τ i using the corresponding previous iteration converged values. Estimate τ n+1 as the mass average of parameter τ for n site types \( \left( {\tau_{n + 1} = \sum\nolimits_{{\text{i}} = 1}^{n} {m_{{\text{i}}} \tau_{{\text{i}}} } } \right). \) Assume first the parameter m for site type n + 1, that is, m n+1 to be the average of the m i values for the adjacent sites to τ n+1, and then normalize the new set of parameters m so that \( \sum\nolimits_{{\text{i}} = 1}^{n + 1} {m_{{\text{i}}} = 1} \) [49].

-

(iv)

Consider that the initial guesses for parameter \( \bar{F}_{1} \) of each site type is evenly distributed within the experimental range of \( \bar{F}_{1} . \) Estimate \( \bar{F}_{1{\text{i}}} , \) the value of parameter \( \bar{F}_{1} \) for site type i, using the following relation [49]:

$$ \bar{F}_{1{\text{i}}} = \bar{F}_{1\hbox{min} } + i\frac{{(\bar{F}_{1\hbox{max} } - \bar{F}_{1\hbox{min} } )}}{(n + 1)}, $$(26)where \( \bar{F}_{1\hbox{max} } \) and \( \bar{F}_{1\hbox{min} } \) are the maximum and minimum values of the experimental range of \( \bar{F}_{1} , \) and n is the total number of site types.

-

(v)

Estimate β i, the initial guess for parameter β for site type i, by assuming that the copolymer is a perfect random copolymer (r 1 r 2 = 1). Then, we can write [49]

$$ \beta_{{\text{i}}} = \bar{F}_{1{\text{i}}} \left( {1 - \bar{F}_{1{\text{i}}} } \right). $$(27) -

(vi)

Compare the experimental MWD and CCD with the corresponding superposed Stockmayer distributions (Eqs. 20, 21), considering all the active site types. Minimize χ 2 using the generalized reduced gradient (GRG2) non-linear optimization algorithm [49]. Note that in general, for n active site types, 4n − 1 parameters are to be estimated. These include m 1, 2,…,n−1, τ 1, 2,…,n, β 1, 2,…,n, and \( \bar{F}_{1(1,\,2, \ldots ,{\text {n}})} \) and one constraint \( \left( {\sum\nolimits_{{\text{i}} = 1}^{n} {m_{{\text{i}}} = 1} } \right) \)[49].

-

(vii)

Increase the number of active site types by 1 and repeat the above calculations until the value of χ 2 does not further decrease significantly.

Rights and permissions

About this article

Cite this article

Atiqullah, M., Cibulková, Z., Černá, A. et al. Effects of supported metallocene catalyst active center multiplicity on antioxidant-stabilized ethylene homo- and copolymers. J Therm Anal Calorim 119, 581–595 (2015). https://doi.org/10.1007/s10973-014-4167-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-014-4167-7