Abstract

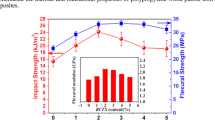

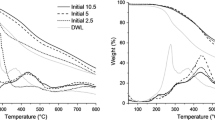

Polypropylene (PP), due to its chemical stability, is considered one of the main responsible of the increasing amount of plastic wastes on earth. To overcome this problem and to reduce the dependence of oil feedstocks, the use of lignocellulosics as fillers or reinforcements in thermoplastic materials has been increasing enormously in the last decades. In the present work, Liquid Wood (a mixture of cellulose, hemp, fax and lignin) was used to prepare, by mechanical mixing followed by thermal extrusion, blends of various PP/Liquid Wood ratios. Differential scanning calorimetry and thermogravimetric analysis experiments were performed in order to verify whether and how much the composition of the blends affects the thermal properties of the obtained compounds. Both calorimetric and thermogravimetric results indicate that the application of PP as a matrix does not limit the processing temperature of Liquid Wood, which may lead to a perfect marketable composite from these components. The addition of Liquid Wood also resulted in enhanced mechanical properties for the PP/Liquid Wood blends.

Similar content being viewed by others

References

Menyhárd A, Faludi G, Varga J. β-Crystallisation tendency and structure of polypropylene grafted by maleic anhydride and its blends with isotactic polypropylene. J Therm Anal Calorim. 2008;93:937–45.

AlMaaded MA, Madi NK, Hodzic A, Soutis C. Influence of additives on recycled polymer blends. J Therm Anal Calorim. 2014;115:811–21.

Perez CJ, Alvarez VA. Non-isothermal crystallization of biodegradable polymer (MaterBi)/polyolefin (PP)/hemp fibres ternary composites. J Therm Anal Calorim. 2015;120:1445–55.

Botelho G, Queiros A, Machado A, Frangiosa P, Ferreira J. Enhancement of the thermo oxidative degradability of polystyrene by chemical modification. Polym Degrad Stab. 2004;86(3):493–7.

Toriz G, Denes F, Young RA. Lignin-polypropylene composites. Part 1: composites from unmodified lignin and polypropylene. Polym Compos. 2002;23:806–13.

Părpăriţă E, Darie RN, Popescu CM, Uddin MDA, Vasile C. Structure–morphology–mechanical properties relationship of some polypropylene/lignocellulosic composites. Mater Des. 2014;56:763–72.

Paukszta D, Borysiak S. The influence of processing and the polymorphism of lignocellulosic fillers on the structure and properties of composite materials—a review. Materials. 2013;6:2747–67.

Chen F, Dai H, Dong X, Yang J, Zhong M. Physical properties of lignin-based polypropylene blends. Polym Compos. 2011;32:1019–25.

Maldhure AV, Ekhe JD, Deenadayalan E. Mechanical properties of polypropylene blended with esterified and alkylated lignin. J Appl Polym Sci. 2012;125:1701–12.

Bozsódi B, Romhányi V, Pataki P, Kun D, Renner K, Pukánszky B. Modification of interactions in polypropylene/lignosulfonate blends. Mater Des. 2016. doi:10.1016/j.matdes.2016.04.061.

Nedelcu D, Ciofu C, Lohan NM. Microindentation and differential scanning calorimetry of “liquid wood”. Compos B. 2013;55:11–5.

Blanco I. Lifetime prediction of food and beverage packaging wastes. J Therm Anal Calorim. 2016. doi:10.1007/s10973-015-5169-9.

Blanco I, Bottino FA, Abate L. Influence of n-alkyl substituents on the thermal behaviour of Polyhedral Oligomeric Silsesquioxanes (POSSs) with different cage’s periphery. Thermochim Acta. 2016;623:50–7.

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N. ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta. 2011;520:1–19.

Genovese A, Shanks RA. Crystallization and melting of isotactic polypropylene in response to temperature modulation. J Therm Anal Calorim. 2004;75:233–48.

Blanco I, Siracusa V. Kinetic study of the thermal and thermo-oxidative degradations of polylactide-modified films for food packaging. J Therm Anal Calorim. 2013;112:1171–7.

Blanco I. End-life prediction of commercial PLA used for food packaging through short term TGA experiments: real chance or low reliability? Chin J Polym Sci. 2014;32:681–9.

Müller P, Imre B, Bere J, Móczó J, Pukánszky B. Physical ageing and molecular mobility in PLA blends and composites. J Therm Anal Calorim. 2015;122:1423–33.

Pucciariello R, Villani V, Bonini C, D’Auria M, Vetere T. Physical properties of straw lignin-based polymer blends. Polymer. 2004;45:4159–69.

Ouyang W, Huang Y, Luo H, Wang D. Poly(Lactic Acid) blended with cellulolytic enzyme lignin: mechanical and thermal properties and morphology evaluation. J Polym Environ. 2012;20:1–9.

Singla RK, Maiti SN, Ghosh AK. Crystallization, morphological, and mechanical response of poly(lactic acid)/lignin-based biodegradable composites. Polym Plast Technol. 2016;55:475–85.

Blanco I, Bottino FA, Bottino P. Influence of symmetry/asymmetry of the nanoparticles structure on the thermal stability of polyhedral oligomeric silsesquioxane/polystyrene nanocomposites. Polym Compos. 2012;33:1903–10.

Blanco I, Bottino FA. Thermal study on phenyl, hepta isobutyl-polyhedral oligomeric silsesquioxane/polystyrene nanocomposites. Polym Compos. 2013;34:225–32.

Abate L, Blanco I, Cicala G, Recca G, Scamporrino A. The influence of chain rigidity on the thermal properties of some novel random copolyethersulfones. Polym Degrad Stab. 2010;95(5):798–802.

Sfiligoj Smole M, Hribernik S, Stana Kleinschek K, Kreže T. Plant fibres for textile and technical applications. In: Grundas S, Stepniewski A, editors. Advances in agrophysical research. InTech; 2013. p. 371–2. doi:10.5772/5237225.

Sahoo S, Misra M, Mohanty AK. Enhanced properties of lignin-based biodegradable polymer composites using injection moulding process. Compos Part A Appl S. 2011;42:1710–8.

Toriz G, Denes F, Young RA. Lignin-polypropylene composites. Part 1: composites from unmodified lignin and polypropylene. Polym Comp. 2002;23(5):806–13.

Reddy JP, Misra M, Mohanty A. Injection moulded biocomposites from oat hull and polypropylene/polylactide blend: fabrication and performance evaluation. Adv Mech Eng. 2013;5:1–8.

Choudhary P, Mohanty S, Nayak SK, Unnikrishnan L. Poly(L-lactide)/polypropylene blends: evaluation of mechanical, thermal, and morphological characteristics. J Appl Polym Sci. 2011;121:3223–37.

Leong YW, Abu Bakar MB, Mohd Ishak ZA, Ariffin A, Pukanszky B. Comparison of the mechanical properties and interfacial interactions between talc, kaolin, and calcium carbonate filled polypropylene composites. J Appl Polym Sci. 2004;91:3315–26.

Graupner N, Fischer H, Ziegmann G, Müssig J. Improvement and analysis of fibre/matrix adhesion of regenerated cellulose fibre reinforced PP-, MAPP- and PLA-composites by the use of Eucalyptus globulus lignin. Compos Part B. 2014;66:117–25.

Acknowledgements

The authors acknowledge the financial support received from Regione Siciliana with the project INTEP “INnovazione TEcnologica e di Processo per il settore manifatturiero” POR 4.1.2a and the Italian Minister for Research and University (MIUR) for the support with the project PON1878 Low Noise and PON BRIT. One of the authors (i.e.G. Cicala) wishes to acknowledge the University of Catania for the support on mechanical testing through the grant NanoCult.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Blanco, I., Cicala, G., Latteri, A. et al. Thermal characterization of a series of lignin-based polypropylene blends. J Therm Anal Calorim 127, 147–153 (2017). https://doi.org/10.1007/s10973-016-5596-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5596-2