Abstract

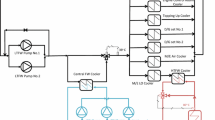

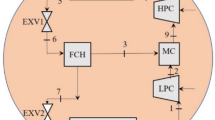

The effects of the seawater-intake temperature on the performance of the refrigeration system which exists on a cargo vessel were introduced in this study. The performance of the real refrigeration system was analysed by using both conventional and advanced exergy analyses and exergoeconomic evaluation. First, a parametric study with different seawater-intake temperatures was carried out by applying conventional exergy and advanced exergy analyses to the refrigeration system considered to identify the pinch point components and processes with high irreversibilities. Then, advanced exergy analyses were applied to overcome technological and physical limitations to increase the knowledge about the refrigeration system. The exergetic efficiency of the refrigeration system was calculated based on varying seawater-intake temperature which enters the condenser while other operating parameters are kept constant. Seawater-intake temperatures were selected in terms of regional seawater temperatures which are assumed to be in the vessel route. As a result of the study, it was determined that the hot entry of the seawater into the condenser causes a reduction in the exergetic efficiency of the refrigeration system. The gap between real system exergetic efficiency and the unavoidable cycle exergetic efficiency increased as the pinch point temperature differences increased in the condenser by approximately 16%. Some of the exergy destruction in the refrigeration system components was unavoidable and constrained by technological and physical limitations. Based on the findings in this study, it has been shown that the greatest improvement in the exergetic efficiency of the cooling system can be achieved by improving the condenser and compressor.

Similar content being viewed by others

Abbreviations

- \(\dot{E}\) :

-

Exergy (kW)

- e :

-

Specific exergy (kJkg−1)

- h :

-

Enthalpy (kJkg−1)

- \(\dot{m}\) :

-

Mass flow rate (kgs-1)

- \(\dot{Q}\) :

-

Heat (W)

- P :

-

Pressure (kPa)

- s:

-

Entropy (kJkg−1K−1)

- T :

-

Temperature (K)

- \(\dot{W}\) :

-

Power (kW)

- ΔP :

-

Pressure drop (kPa)

- ΔT :

-

Temperature differences (K)

- ε:

-

Exergy efficiency (%)

- y :

-

Exergy destruction ratio (%)

- x :

-

Quality ratio (%)

- AV:

-

Avoidable

- CD:

-

Condenser

- CM:

-

Compressor

- D:

-

Destruction

- EN:

-

Endogenous

- EV:

-

Evaporator

- EX:

-

Exogenous

- F:

-

Fuel

- in:

-

Inlet

- k:

-

Component

- L:

-

Loss, liquid

- LT:

-

Low temperature

- M:

-

Mechanic

- mex:

-

Mexogenous

- MT:

-

Medium temperature

- 0:

-

Dead state

- Out:

-

Outlet

- P:

-

Product

- R:

-

Real

- T:

-

Thermal

- Th:

-

Theory

- Tot:

-

Total

- TV:

-

Throttling valve

- UN:

-

Unavoidable

- V:

-

Vapour

- W:

-

Water

References

Maclaine-cross I L, Leonardi E. Comparative performance of hydrocarbon refrigerants. I.I.F-I.I.R- commissions E2, E1, B1, B2 Melbourne (Australia)-1996 11th 14th February.

Tiwari P, Pandey P. Exergy analysis of vapour compression refrigeration cycle-a review. Int J Core Eng Manag. 2015;2:181–6.

Kumar M, Nayak RK. Exergy analysis of a vapour compression refrigeration system using R-134a and hydrocarbon as refrigerants. Int J Res Eng Appl Manag. 2018;4:91–5.

Soni J, Gupta RC. Exergy analysis of vapour compression refrigeration system with using R-407C and R-410A. Int J Eng Res Technol. 2012;1(7):1–12.

Yadav P. Sharma A. Exergy analysis of R134a based vapour compression refrigeration tutor. In: National conference on advances in engineering technology and management. Maharishi Markandeshwar University; 2015. pp. 73–77

Amarisa C, Tsamosb KM, Tassoub SA. Analysis of an R744 typical booster configuration, an R744 parallel-compressor booster configuration and an R717/R744 cascade refrigeration system for retail food applications. Part 1: thermodynamic analysis. Energy Procedia. 2019;161:259–67.

Yumrutaş R, Kunduz M, Kanoğlu M. Exergy analysis of vapour compression refrigeration systems. Exergy Int J. 2002;2:266–72.

Kalla SK, Arora BB, Usmani JA. Performance analysis of R22 its substitutes in air conditioners. J Therm Eng. 2018;4:1724–36.

Kelly S, Tsatsaronis G, Morosuk T. Advanced exergetic analysis: approaches for splitting the exergy destruction into endogenous and exogenous parts. Energy. 2009;34:384–91.

Fabrian B, Toung-Wang N, Kjear JJ, and Brian E. Energy, exergy and advanced exergy analysis of a milk processing factory. In: Proceedings of ECOS, The 29th International conference on efficiency, cost, optimization, simulation and environmental impact of energy system. 2016; 1–13.

Tsatsaronis G, Morosuk T. Advanced thermodynamic (exergetic) analysis. In: 6th European thermal science conference (Eurotherm 2012) J Phys Conf Ser. 2012;395:4–7.

Ghorbani B, Roshani H. Advanced exergy and exergoeconomic analysis of theintegratedstructure of simultaneous production of NGL recovery and liquefaction. Transp Phenomena Nano Micro Scales. 2018;6:8–14. https://doi.org/10.22111/tpnms.2018.23743.1140.

Şöhret Y, Açıkkalp E, Hepbaşlı A, Karakoç TH. Advanced exergy analysis of an aircraft gas turbine engine: splitting exergy destructions into parts. Energy. 2015;90:1219–28.

Bai T, Yu J, Yan G. Advanced exergy analysis of an ejector expansion transcritical CO2 refrigeration system. Energ Convers Manage. 2016;126:850–61.

Gullo P, Hafner A, Banasiak K. Thermodynamic performance investigation of commercial R744 booster refrigeration plants based on advanced analysis. Energies. 2019;12:2–24. https://doi.org/10.3390/en12030354.

Chen J, Havtun H, Palm B. Conventional and advanced exergy analysis of an ejector refrigeration system. Appl Energ. 2015;144:139–51.

Balli O. Advanced exergy analysis to evaluate the performance of a military air craft turbojet engine (TJE) with after burner system: splitting exergy destruction into unavoidable/avoidable and endogenous/exogenous. Appl Therm Eng. 2017;111:152–69.

Liu H, He Q, Saeed SB. Thermodynamic analysis of a compressed air energy storage system through advanced exergetic analysis. J Renew Sustain Energy. 2016;8:034101/1-17. https://doi.org/10.1063/1.4948515.

Özgür AE, Kabul A, Kizilkan Ö. Exergy analysis of refrigeration systems using an alternative refrigerant (hfo-1234yf) to R-134a. Int J Low Carbon Technol. 2014;9:56–62. https://doi.org/10.1093/ijlct/cts054.

Azizi T, Boyaghchi FA. Assessment of a real combined cycle power plant with supplementary firing based on advanced exergy/exergoeconomic methods. IJST-T Mech Eng. 2014;15:28–58.

Vuckovic GD, Vukic MV, Stojiljkovic MM, Vuckovic DD. Avoidable and unavoidable exergy destruction and exergoeconomic evaluation of the thermal processes in a real industrial plant. Therm Sci. 2012;16:433–46. https://doi.org/10.2298/TSCI120503181V.

Ukey R, Chaudhary S. Exergy analysis of domestic refrigerator with different refrigerants. Int J Sci Eng Res. 2012;3:1–5.

Singh G, Singh PJ, Tyagi VV, Pandey AK. Thermal and exergoeconomic analysis of a dairy food processing plant. J Therm Anal Calorim. 2019;136:1365–82. https://doi.org/10.1007/s10973-018-7781-y.

Singh G, Singh PJ, Tyagi VV, Barnwal P, Pandey AK. Exergy and thermoeconomic analysis of cream pasteurisation plant. J Therm Anal Calorim. 2019;137:1381–400. https://doi.org/10.1007/s10973-019-08016-y.

Anand S, Tyagi SK. Exergy analysis and experimental study of a vapour compression refrigeration cycle. J Therm Anal Calorim. 2012;110:961–71. https://doi.org/10.1007/s10973-011-1904-z.

Gill J, Singh J, Ohunakin OS, Adelekan DS. Component-wise exergy analysis using adaptive neuro-fuzzy inference system in vapor compression refrigeration system. J Therm Anal Calorim. 2019;136:2111–23. https://doi.org/10.1007/s10973-018-7857-8.

Gullo P, Elmegaard B, Cortella C. Advanced exergy analysis of a R744 booster refrigeration system with parallel compression. Energy. 2016;107:567–71. https://doi.org/10.1016/j.energy.2016.04.043.

Shafee A, Sheikholeslami M, Jafaryar M, Selimefendigil F, Bhatti MM, Babazadeh H. Numerical modeling of turbulent behavior of nanomaterial exergy loss and flow through a cicular channel. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09568-0.

Seyednezhad M, Shrikholeslami M, Ali JA, Shafee A, Nguyen TK. Nanoparticles for water desalination in solar heat exchanger. J Therm Anal Calorim. 2019;139(1619–1636):2020. https://doi.org/10.1007/s10973-019-08634-6.

Shekholeslami M, Jafaryar M, Shafee A, Babazdeh H. Acceleration of discharge process of clean energy storage unit with insertion of porous foam considering nanoparticcle enhanced parafin. J Clean Prod. 2020. https://doi.org/10.1016/j.jclepro.2020.121206.

Sheikholeslami M, Jafaryar M, Shafee A, Li Z, Haq R. Heat transfer of nanoparticles employing innovative turbulator considering entropy generation. Int J Heat Mass Transf. 2019;136:1233–40. https://doi.org/10.1016/j.ijheatmasstransfer.2019.03.091.

Kotas TJ. The exergy method of thermal plant analysis. Florida: Krieger Publishing Company; 1985.

Wang L, Yang Z, Sharma S, Mian A, Lin TE, Tsatsaronis G, Marechal F, Yang Y. A review of evaluation, optimization and synthesis of energy systems: methodology and application to thermal power plants. Energies. 2019;12:73. https://doi.org/10.3390/en12010073.

Chen, J. Investigation of vapour ejectors in heat driven ejectors refrigeration system. Doctoral thesis. Division of applied thermodynamics and refrigeration department of energy technology, Royal Institute of technology, KTH, SE-100 44 Stockholm, Sweden.2014.

Acknowledgements

The authors would like to thank Prof. Dr. Teoman AYHAN for his valuable comments, which have been utilized in improving the quality of the paper. Also, the authors would like to thank NCCB NAVIGATION S.A. Company for the technical data to the present research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nacak, C., Saraç, B. The performance assessment of a refrigeration system which exists on a cargo vessel influenced by seawater-intake temperature. J Therm Anal Calorim 146, 1229–1243 (2021). https://doi.org/10.1007/s10973-020-10060-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10060-y