Abstract

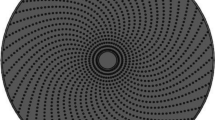

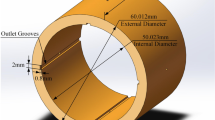

In the mechanical tribology research, reasonable and effective improvement of lubrication performance for friction pairs of sleeve bearings is one of the hot topics, surface micro texture processing technology has gradually become an important way to improve the lubrication performance of friction pairs. Taking the friction pair model of infinite wide bearing as the research object, the Reynolds equation on the fluid lubrication of the friction pair is established. According to the static characterization equation of the micro texture friction pair, the influence of the depth and the coverage rate of micro texture on the lubrication performance of the friction pair is studied. According to the theoretical analysis, in order to simulate the actual contact condition of the sleeve bearing friction pair more truly, 45 steel is selected as friction material to prepare the ring–ring contact friction pair. The micro textures of a certain shape are machined on the surface of the specimen by laser micro carving, and the friction and wear experiments are carried out by universal friction tester. Theoretical analysis and experimental results show that the lubrication performance of friction pair with reasonable distribution of micro texture is improved obviously, and the reasonable selection of micro texture depth and coverage rate can effectively improve the friction properties of friction pairs.

Similar content being viewed by others

References

Gorlenko AO, Davydov SV (2018) Deposition of coatings for raising the wear resistance of friction surfaces of spherical sliding bearings. Met Sci Heat Treat 59(9–10):1–5

Miszczak A, Wierzcholski K (2014) A method of the wear prognosis of sliding bearings. Arch Mech Eng 61(4):553–570

Yu HW, Deng HS, Huang W, Wang XL (2011) Effects of micro-dimple arrangements on tribological performance of sliding surfaces. J China Univ Min Technol 40(06):943–948

Yu RF, Chen W (2016) Study of elastohydrodynamic lubrication of radial bearing with surface texture. J Xihua Univ Nat Sci 35(03):1–6

Sun JR, Dai ZD (2008) Non smooth surface bionics (I). Prog Nat Sci 03:241–246

Hamilton DB, Halavit JA (1966) A theory of lubrication by micro irregularities. J Basic Eng 88(1):177–185

Siripuram RB, Stephens L (2004) Effect of deterministic asperity geometry on hydrodynamic lubrication. J Tribol 126(6):527–534

Ma CB (2010) Study on the lubrication computational model and antifriction performance of textured surfaces. China University of Mining and Technology

Peng LL, Wang JG, Peng YY, Hong YF (2016) Effects of surface texture on turbulent lubrication of water-lubricated journal bearing. Lubr Eng 41(02):1–7

Yin MH, Chen GD, Gao DC, Wang L (2016) Effects of three types of surface texture on the performances of journal bearing. J Harbin Inst Technol 48(01):159–164

Lu XM, Wang QD, Xiao JM (2016) CFD-analysis on the effect of cavitation of textured surface on hydrodynamic lubrication. Lubr Eng 41(05):70–75

Han YX, Fu YH (2018) Investigation of surface texture influence on hydrodynamic performance of parallel slider bearing under transient condition. Meccanica 53(8):2053–2066

Kumar V, Sharma SC (2018) Influence of dimple geometry and micro-roughness orientation on performance of textured hybrid thrust pad bearing. Meccanica 53(14):3579–3606

Etsion L, Sher E (2009) Improving fuel efficiency with laser surface textured piston rings. Tribol Int 42(4):542–547

Braun D, Greiner C, Schneider J et al (2014) Efficiency of laser surface texturing in the reduction of friction under mixed lubrication. Tribol Int 77(6):142–147

Chen P, Xiang X et al (2016) Effect of triangular texture on the tribological performance of die steel with TiN coatings under lubricated sliding condition. Appl Surf Sci 10(389):361–368

Hua JX, Xie X et al (2017) Tribological properties of micro-textured self-lubricating surface in oil medium. China Surf Eng 30(2):35–40

Li WZ, Xu YQ, Sun J, Liu KA, Zeng TW (2017) Characterization methods and influence factors of running-in wear between sliding joint surfaces. China Surf Eng 30(01):125–131

Khatri Chandra B, Sharma Satish C (2018) Analysis of textured multi-lobe non-recessed hybrid journal bearings with various restrictors. Int J Mech Sci 145:258–286

Li XL, Yue W, Huang F, Kang JJ, Fu ZQ (2017) Effect of wear particle size on dry tribological properties of surface texturing titanium. J Mech Eng 53(24):25–33

Zhang ZM (1986) Hydrodynamic lubrication theory of sliding bearing. Higher Education Press, Beijing

Acknowledgements

This work was supported by the grant from China Postdoctoral Science Foundation funded project (No. 2017M612304), Shandong Provincial Postdoctoral Innovation Foundation (No. 201701016), supported by SDUST Research Fund (No. 2015JQJH104), Qingdao Postdoctoral Research funded project, Key Laboratory of High-efficiency and Clean Mechanical Manufacture at Shandong University, Ministry of Education, Key Research, National Natural Science Foundation of China (No. 51305242).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, L., Guo, S., Wei, Y. et al. Optimization research on the lubrication characteristics for friction pairs surface of journal bearings with micro texture. Meccanica 54, 1135–1148 (2019). https://doi.org/10.1007/s11012-019-01015-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-019-01015-1