Abstract

Purpose

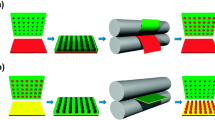

A novel concept is presented for the formation of stable suspensions composed of low density flocs of high aspect ratio drug particles in hydrofluoroalkane (HFA) propellants, and for subdividing (templating) the flocs with aerosolized HFA droplets to achieve high fine particle fractions with a pressurized metered dose inhaler.

Methods

Bovine serum albumin (BSA) nanorods, produced by thin film freezing (TFF), were added to HFA to form a suspension. Particle properties were analyzed with an Anderson cascade impactor (ACI), static and dynamic light scattering and optical microscopy.

Results

The space filling flocs in HFA were stable against settling for one year. The pMDI produced high fine particle fractions (38–47%) with an emitted dose of 0.7 mg/actuation. The atomized HFA droplets break apart, that is template, the highly open flocs. Upon evaporation of HFA, capillary forces shrink the templated flocs to produce porous particles with optimal aerodynamic diameters for deep lung delivery.

Conclusions

Open flocs composed of nanorods, stable against settling, may be templated during actuation with a pMDI to produce optimal aerodynamic diameters and high fine particle fractions. This concept is applicable to a wide variety of drugs without the need for surfactants or cosolvents to stabilize the primary particles.

Similar content being viewed by others

References

R. U. Agu, M. I. Ugwoke, M. Armand, R. Kinget, and N. Verbeke. The lung as a route for systemic delivery of therapeutic proteins and peptides. Respir. Res. 2:198–209 (2001) doi:10.1186/rr58.

A. L. Adjei, and P. K. Gupta. Inhalation delivery of therapeutic peptides and proteins. Int. J. Pharm. 159:259 (1997).

S. White, D. B. Bennett, S. Cheu, P. W. Conley, D. B. Guzek, S. Gray, J. Howard, R. Malcolmson, J. M. Parker, P. Roberts, N. Sadrzadeh, J. D. Schumacher, S. Seshadri, G. W. Sluggett, C. L. Stevenson, and N. J. Harper. EXUBERA: pharmaceutical development of a novel product for pulmonary delivery of insulin. Diabetes Technol. Ther. 7:896–906 (2005) doi:10.1089/dia.2005.7.896.

S. A. Shoyele, and A. Slowey. Prospects of formulating proteins/peptides as aerosols for pulmonary drug delivery. Int. J. Pharm. 314:1–8 (2006) doi:10.1016/j.ijpharm.2006.02.014.

H. M. Courrier, N. Butz, and T. F. Vandamme. Pulmonary drug delivery systems: recent developments and prospects. Crit. Rev. Ther. Drug Carr. Syst. 19:425–498 (2002) doi:10.1615/CritRevTherDrugCarrierSyst.v19.i45.40.

M. J. Kwon, J. H. Bae, J. J. Kim, K. Na, and E. S. Lee. Long acting porous microparticle for pulmonary protein delivery. Int. J. Pharm. 333:5–9 (2007) doi:10.1016/j.ijpharm.2007.01.016.

J. S. Patton, and P. R. Byron. Inhaling medicines: delivering drugs to the body through the lungs. Nature Reviews Drug Discovery. 6:67–74 (2007) doi:10.1038/nrd2153.

V. Codrons, F. Vanderbist, R. K. Verbeeck, M. Arras, D. Lison, V. Preat, and R. Vanbever. Systemic delivery of parathyroid hormone (1–34) using inhalation dry powders in rats. J. Pharm. Sci. 92:938–950 (2003) doi:10.1002/jps.10346.

L. Garcia-Contreras, and H. D. C. Smyth. Liquid-spray or dry-powder systems for inhaled delivery of peptide and proteins? American Journal of Drug Delivery. 3:29–45 (2005) doi:10.2165/00137696-200503010-00004.

D. Traini, P. Young, P. Rogueda, and R. Price. The use of AFM and surface energy measurements to investigate drug–canister material interactions in a model pressurized metered dose inhaler formulation. Aerosol Sci. Tech. 40:227–236 (2006) doi:10.1080/02786820500543316.

P. Rogueda. Novel hydrofluoroalkane suspension formulations for respiratory drug delivery. Expert Opinion on Drug Delivery. 2:625–638 (2005) doi:10.1517/17425247.2.4.625.

R. O. Williams III, and J. Liu. Formulation of a protein with propellant HFA 134a for aerosol delivery. Eur. J. Pharm. Sci. 7:137–144 (1999) doi:10.1016/S0928-0987(98)00015-3.

R. O. Williams III, M. Repka, and J. Liu. Influence of propellant composition on drug delivery from a pressurized metered-dose inhaler. Drug Dev. Ind. Pharm. 24:763–770 (1998) doi:10.3109/03639049809082724.

K. A. Johnson. Interfacial phenomena and phase behavior in metered dose inhaler formulations. In A. J. Hickey (ed.), Inhalation Aerosols: Physical and Biological Basis for Therapy, Vol. 221. Lung Biology in Health and Disease, 2007.

E. A. Quinn, R. T. Forbes, A. C. Williams, M. J. Oliver, L. McKenzie, and T. S. Purewal. Protein conformational stability in the hydrofluoroalkane propellants tetrafluoroethane and heptafluoropropane analyzed by Fourier transform Raman spectroscopy. Int. J. Pharm. 186:31–41 (1999) doi:10.1016/S0378-5173(99)00135-0.

M. J. Oliver, L. McKenzie, W. D. Graffiths, G. R. Morgan, and N. O’Kelly. Initial assessment of a protein formulated in pressurized MDIS for pulmonary delivery. In RDD VII, 2000.

C. Benfait. Kos reports achievement of new research and development milestones. Kos Press Release (2004).

J. Heyder, J. Gebhart, G. Rudolf, C. F. Schiller, and W. Stahlhofen. Deposition of particles in the human respiratory tract in the size range 0.005–15 µm. J. Aerosol Sci. 17:811–825 (1986) doi:10.1016/0021-8502(86)90035-2.

A. Ben-Jebria, D. Chen, M. L. Eskew, R. Vanbever, R. Langer, and D. A. Edwards. Large porous particles for sustained protection from carbachol-induced bronchoconstriction in guinea pigs. Pharm. Res. 16:555–561 (1999) doi:10.1023/A:1018879331061.

N. Tsapis, D. Bennett, B. Jackson, D. A. Weitz, and D. A. Edwards. Trojan particles: large porous carriers of nanoparticles for drug delivery. Proc. Natl. Acad. Sci. U. S. A. 99:12001–12005 (2002) doi:10.1073/pnas.182233999.

L. A. Dellamary, T. E. Tarara, D. J. Smith, C. H. Woelk, A. Adractas, M. L. Costello, H. Gill, and J. G. Weers. Hollow porous particles in metered dose inhalers. Pharm. Res. 17:168–174 (2000) doi:10.1023/A:1007513213292.

Y.-F. Maa, P.-A. Nguyen, T. Sweeney, S. J. Shire, and C. C. Hsu. Protein inhalation powders: spray drying vs spray freeze drying. Pharm. Res. 16:249–254 (1999) doi:10.1023/A:1018828425184.

Y.-F. Maa, and H. R. Costantino. Spray freeze-drying of biopharmaceuticals: applications and stability considerations. In H. R. Costantino, and M. J. Pikal (eds.), Biotechnology: Pharmaceutical Aspects. 2. Lyophilization of Biopharmaceuticals, Vol. 2, American Association of Pharmaceutical Scientists, Arlington, 2004, pp. 519–561.

Z. Yu, A. S. Garcia, K. P. Johnston, and R. O. Williams III. Spray freezing into liquid nitrogen for highly stable protein nanostructured microparticles. Eur. J. Pharm. Biopharm. 58:529–537 (2004) doi:10.1016/j.ejpb.2004.04.018.

J. D. Engstrom, D. T. Simpson, E. Lai, R. O. Williams III, and K. P. Johnston. Morphology of protein particles produced by spray freezing of concentrated solutions. Eur. J. Pharm. Biopharm. 65:149–162 (2007) doi:10.1016/j.ejpb.2006.08.005.

J. D. Engstrom, D. T. Simpson, C. Cloonan, E. Lai, R. O. Williams III, G. B. Kitto, and K. P. Johnston. Stable high surface area lactate dehydrogenase particles produced by spray freezing into liquid nitrogen. Eur. J. Pharm. Biopharm. 65:163–174 (2007) doi:10.1016/j.ejpb.2006.08.002.

Z. Yu, K. P. Johnston, and R. O. Williams III. Spray freezing into liquid versus spray-freeze drying: Influence of atomization on protein aggregation and biological activity. Eur. J. Pharm. Sci. 27:9–18 (2006) doi:10.1016/j.ejps.2005.08.010.

Z. Yu, T. L. Rogers, J. Hu, K. P. Johnston, and R. O. Williams III. Preparation and characterization of microparticles containing peptide produced by a novel process: spray freezing into liquid. Eur. J. Pharm. Biopharm. 54:221–228 (2002) doi:10.1016/S0939-6411(02)00050-4.

J. D. Engstrom, E. S. Lai, B. Ludher, B. Chen, T. E. Milner, G. B. Kitto, R. O. Williams III, and K. P. Johnston. Formation of stable submicron protein particles by thin film freezing. Pharm. Res. 25:1334–1346 (2008) doi:10.1007/s11095-008-9540-4.

S. D. Webb, S. L. Golledge, J. L. Cleland, J. F. Carpenter, and T. W. Randolph. Surface adsorption of recombinant human interferon-γ in lyophilized and spray-lyophilized formulations. J. Pharm. Sci. 91:1474–1487 (2002) doi:10.1002/jps.10135.

X. C. Nguyen, J. D. Herberger, and P. A. Burke. Protein powders for encapsulation: a comparison of spray-freeze drying and spray drying of darbepoetin alfa. Pharm. Res. 21:507–514 (2004) doi:10.1023/B:PHAM.0000019306.89420.f0.

Y.-F. Maa, and S. J. Prestrelski. Biopharmaceutical powders: particle formation and formulation considerations. Curr. Pharm. Biotechnol. 1:283–302 (2000) doi:10.2174/1389201003378898.

I. Gonda. Development of a systematic theory of suspension inhalation aerosols. I. A framework to study the effects of aggregation on the aerodynamic behavior of drug particles. Int. J. Pharm. 27:99–116 (1985) doi:10.1016/0378–5173(85)90189-9.

Y.-H. Liao, M. B. Brown, S. A. Jones, T. Nazir, and G. P. Martin. The effects of polyvinyl alcohol on the in vitro stability and delivery of spray-dried protein particles from surfactant-free HFA 134a-based pressurised metered dose inhalers. Int. J. Pharm. 304:29–39 (2005) doi:10.1016/j.ijpharm.2005.07.013.

M. Keller. Innovations and perspectives of metered dose inhalers in pulmonary drug delivery. Int. J. Pharm. 186:81–90 (1999) doi:10.1016/S0378-5173(99)00132-5.

C. Vervaet, and P. R. Byron. Drug-surfactant-propellant interactions in HFA-formulations. Int. J. Pharm. 186:13–30 (1999) doi:10.1016/S0378-5173(99)00134-9.

F. E. Blondino, and P. R. Byron. Surfactant dissolution and water solubilization in chlorine-free liquified gas propellants. Drug Dev. Ind. Pharm. 24:935–945 (1998) doi:10.3109/03639049809097273.

R. P. S. Peguin, P. Selvam, and S. R. P. da Rocha. Microscopic and thermodynamic properties of the HFA134a-water interface: atomistic computer simulations and tensiometry under pressure. Langmuir. 22:8826–8830 (2006) doi:10.1021/la0608157.

L. Wu, R. P. S. Peguin, P. Selvam, U. Chokshi, and S. R. P. da Rocha. Molecular scale behavior in alternative propellant-based inhaler formulations. In A. J. Hickey (ed), Inhalation Aerosols: Physical and biological basis for therapy, Vol. 221. Lung Biology in Health and Disease, 2007.

R. Vanbever, J. D. Mintzes, J. Wang, J. Nice, D. Chen, R. Batycky, R. Langer, and D. A. Edwards. Formulation and physical characterization of large porous particles for inhalation. Pharm. Res. 16:1735–1742 (1999) doi:10.1023/A:1018910200420.

D. A. Edwards, J. Hanes, G. Caponetti, J. Hrkach, A. Ben-Jebria, M. L. Eskew, J. Mintzes, D. Deaver, N. Lotan, and R. Langer. Large porous particles for pulmonary drug delivery. Science. 276:1868–1871 (1997) doi:10.1126/science.276.5320.1868.

J. Tam, J. T. McConville, R. O. Williams III, and K. P. Johnston. Amorphous cyclosporin A nanodispersions for enhanced pulmonary deposition and dissolution. J. Pharm. Sci. in press (2008) doi:10.1002/jps.21367.

Z. Jiang, and Y. Guan. Flocculation morphology: effect of particulate shape and coagulant species on flocculation. Water Sci. Technol. 53:9–16 (2006) doi:10.2166/wst.2006.339.

I. Goodarz-Nia, and D. N. Sutherland. Floc simulation. Effects of particle size and shape. Chem. Eng. Sci. 30:407–12 (1975) doi:10.1016/0009-2509(75)85005-6.

P. C. Hiemenz and R. Rajagopalan. Principles of colloid and surface chemistry, Marcel Dekker, New York, 1997.

A. P. Philipse, and A. M. Wierenga. On the density and structure formation in gels and clusters of colloidal rods and fibers. Langmuir. 14:49–54 (1998) doi:10.1021/la9703757.

A. P. Philipse. The random contact equation and its implications for (colloidal) rods in packings, suspensions, and anisotropic powders. Langmuir. 12:5971 (1996) doi:10.1021/la960869o.

R. G. Larson. The structure and rheology of complex fluids. Oxford University Press, New York, 1999.

P. G. Smith Jr., W. Ryoo, and K. P. Johnston. Electrostatically stabilized metal oxide particle dispersions in carbon dioxide. J. Phys. Chem. B. 109:20155–20165 (2005) doi:10.1021/jp0532521.

Y. Kim, S. H. Atwell, and R. G. Bell. Determination of water in pressurized pharmaceutical metered dose aerosol products. Drug Dev. Ind. Pharm. 18:2185–2195 (1992) doi:10.3109/03639049209038756.

R. O. Williams III, J. Liu, and J. J. Koleng. Influence of metering chamber volume and water level on the emitted dose of a suspension-based pMDI containing propellant 134a. Pharm. Res. 14:438–443 (1997) doi:10.1023/A:1012087130114.

E. Berlin, and M. J. Pallansch. Densities of several proteins and L-amino acids in the dry state. J. Phys. Chem. 72:1887–1889 (1968) doi:10.1021/j100852a004.

P. G. A. Rogueda. HPFP, a model propellant for pMDIs. Drug Dev. Ind. Pharm. 29:39–49 (2003) doi:10.1081/DDC-120016682.

R. Ashayer, P. F. Luckham, S. Manimaaran, and P. Rogueda. Investigation of the molecular interactions in a pMDI formulation by atomic force microscopy. Eur. J. Pharm. Sci. 21:533–543 (2004) doi:10.1016/j.ejps.2003.12.003.

D. Traini, M. Young Paul, P. Rogueda, and R. Price. In vitro investigation of drug particulates interactions and aerosol performance of pressurised metered dose inhalers. Pharm. Res. 24:125–135 (2007) doi:10.1007/s11095-006-9130-2.

S. L. Nail, S. Jiang, S. Chongprasert, and S. A. Knopp. Fundamentals of freeze-drying. In S. L. Nailand, and M. J. Akers (eds.), Pharmaceutical Biotechnology. 14. Development and Manufacture of Protein Pharmaceuticals, Vol. 14, Kluwer, New York, 2002, pp. 281–360.

S. D. Webb, J. L. Cleland, J. F. Carpenter, and T. W. Randolph. A new mechanism for decreasing aggregation of recombinant human interferon-g by a surfactant: slowed dissolution of lyophilized formulations in a solution containing 0.03% polysorbate 20. J. Pharm. Sci. 91:543–558 (2002) doi:10.1002/jps.10033.

J. F. Carpenter, B. S. Chang, W. Garzon-Rodriguez, and T. W. Randolph. Rational design of stable lyophilized protein formulations: theory and practice. In J. F. Carpenter, and M. C. Manning (eds.), Pharmaceutical Biotechnology. 13. Rational Design of Stable Protein Formulations, Vol. 13, Kluwer, New York, 2002, pp. 109–133.

A. Farahnaky, F. Badii, I. A. Farhat, J. R. Mitchell, and S. E. Hill. Enthalpy relaxation of bovine serum albumin and implications for its storage in the glassy state. Biopolymers. 78:69–77 (2005) doi:10.1002/bip.20265.

B. Y. Shekunov, P. Chattopadhyay, H. H. Y. Tong, and A. H. L. Chow. Particle size analysis in pharmaceutics: principles, methods and applications. Pharm. Res. 24:203–227 (2007) doi:10.1007/s11095-006-9146-7.

W. H. Finlay. The mechanics of inhaled pharmaceutical aerosols, Academic,New York, 2001.

A. Sihvola. Electromagnetic mixing formulas and applications, Institute of Electrical Engineers, London, 1999.

W. B. Russel, D. A. Saville, and W. R. Schowalter. Colloidal dispersions, Cambridge University Press, Cambridge, 1989.

D. Traini, P. Rogueda, P. Young, and R. Price. Surface Energy and Interparticle Forces Correlations in Model pMDI Formulations. Pharm. Res. 22:816–825 (2005) doi:10.1007/s11095-005-2599-2.

M. A. Bevan. Effect of adsorbed polymer on the interparticle potential, chemical engineering. Carnegie Mellon University, Pittsburgh, 1999.

P. Tang, J. Greenwood, and J. A. Raper. A model to describe the settling behavior of fractal aggregates. J. Colloid Interface Sci. 247:210–219 (2002) doi:10.1006/jcis.2001.8028.

C. Fargues, and C. Turchiuli. Structural characterization of flocs in relation to their settling performances. Chem. Eng. Res. Des. 82:1517 (2004) doi:10.1205/cerd.82.11.1517.52026.

H. Abramowitz, P. S. Shah, P. F. Green, and K. P. Johnston. Welding colloidal crystals with carbon dioxide. Macromolecules. 37:7316–7324 (2004) doi:10.1021/ma048961b.

D. R. Ulrich. Chemical processing of ceramics. Chem. Eng. News. 68:28–40 (1990).

H. D. C. Smyth, A. J. Hickey, and R. M. Evans. Aerosol generation from propellant-driven metered dose inhalers. In J. Hickey Anthony (ed), Inhalation Aerosols: Physical and Biological Basis for Therapy, Vol. 221, Lung biology in health and disease, 2007, pp. 399–416.

D. L. French, D. A. Edwards, and R. W. Niven. The influence of formulation on emission, deaggregation and deposition of dry powders for inhalation. J. Aerosol Sci. 27:769–783 (1996) doi:10.1016/0021-8502(96)00021-3.

T. L. Rogers, A. C. Nelsen, J. Hu, J. N. Brown, M. Sarkari, T. J. Young, K. P. Johnston, and R. O. Williams III. A novel particle engineering technology to enhance dissolution of poorly water soluble drugs: spray-freezing into liquid. Eur. J. Pharm. Biopharm. 54:271–280 (2002) doi:10.1016/S0939-6411(02)00063-2.

T. L. Rogers, K. A. Overhoff, P. Shah, P. Santiago, M. J. Yacaman, K. P. Johnston, and R. O. Williams III. Micronized powders of a poorly water soluble drug produced by a spray-freezing into liquid-emulsion process. Eur. J. Pharm. Biopharm. 55:161–72 (2003) doi:10.1016/S0939-6411(02)00193-5.

J. Israelachvili. Intermolecular and surface forces. Academic, San Diego, 1992.

S. Takashima. Proton fluctuation in protein. Experimental study of the Kirkwood–Shumaker theory. J. Phys. Chem. 69:2281–2286 (1965) doi:10.1021/j100891a023.

R. Tadmor. The London–van der Waals interaction energy between objects of various geometries. J. Phys. Condens. Matter. 13:L195–L202 (2001) doi:10.1088/0953-8984/13/9/101.

Acknowledgements

This material is supported in part by the STC Program of the National Science Foundation under Agreement No. CHE987664, the Robert A. Welch Foundation, and the Process Science and Technology Center at the University of Texas. The authors also wish to thank TSI for access to the APS 3321.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Bruggeman mixing rule

For porous particles or suspensions with a BSA particle volume fraction ϕ, the effective refractive index n e and dielectric constant ɛ e can be calculated from the following Bruggeman mixing relationships

where ϕ can be either ϕ g or ϕ f, the subscript A denotes air or HFA 227, and B denotes BSA.

Attractive van der Waals equations

The Φ vdw is directly proportional to the Hamaker constant A 121 for one particle interacting with another (subscript 1) across solvent, such as HFA 227 or acetonitrile, (subscript 2) as a function of the particle geometry (74). The Hamaker constant A 121 may be approximated by

where A 11 and A 22 are the pure Hamaker constants for BSA and the suspending media interacting across a vacuum, respectively. These values were calculated from Lifshitz theory (74,75). To determine A 11 for porous BSA particles in HFA 227, ɛ e and n e were calculated with the Bruggeman mixing rule (Eqs. 9 and 10) at ϕ = 0.5 in HFA 227 (40,62). The van der Waals attractive potential between identical spherical particles (74)

which has an attractive force F vdw given as

where R is the spherical particle radius and h is the separation distance between the particle surfaces and for identical hollow spheres with solid shells (76)

where t is the shell thickness. For identical rods, E vdw can be calculated for parallel

or crossed cylinders

where L is the cylinder length. The values from Eq. 15 and 16 were averaged to give equal weight to the two orientations (Table III).

Space filling floc derivation

A vial filled with protein particles of total mass m and primary particle density ρ p into a given volume V of HFA 227 has a volume fraction ϕ v defined as

The volume fraction of particles in a floc ϕ f is

where V p and V f are the volume of a spherical primary particle and a spherical floc, respectively, and k is the number of primary particles in a floc.

The volume fraction of flocs in HFA ϕ flocs is defined as

where N f is the total number of flocs in suspension. N f = N p /k where N p = m/m p is the total number of primary particles in suspension and m p = V p·ρ p is the mass of a primary particle. Substitution into Eq. 19 gives

Rights and permissions

About this article

Cite this article

Engstrom, J.D., Tam, J.M., Miller, M.A. et al. Templated Open Flocs of Nanorods for Enhanced Pulmonary Delivery with Pressurized Metered Dose Inhalers. Pharm Res 26, 101–117 (2009). https://doi.org/10.1007/s11095-008-9707-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-008-9707-z