ABSTRACT

Purpose

Stable vaccines with long shelf lives and reduced dependency on the cold chain are ideal for stockpiling and rapid deployment during public emergencies, including pandemics. Spray drying is a low-cost process that has potential to produce vaccines stable at a wide range of temperatures. Our aim was to develop a stable formulation of a recombinant H1N1 influenza hemagglutinin vaccine candidate and take it to pilot-scale spray-drying production.

Methods

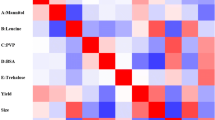

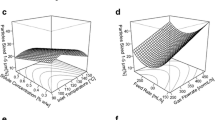

Eight formulations containing different excipients were produced and assayed for antigen stability, powder characteristics, and immunogenicity after storage at a range of temperatures, resulting in the identification of four promising candidates. A pilot-scale spray-drying process was then developed for further testing of one formulation.

Results

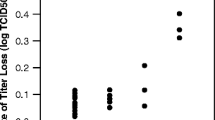

The pilot-scale process was used to reproducibly manufacture three batches of the selected formulation with yields >90%. All batches had stable physical properties and in vitro potency for 6 months at temperatures from −20°C to +50°C. Formulations stored for 3 months elicited immunogenic responses in mice equivalent to a frozen lot of bulk vaccine used as a stability control.

Conclusions

This study demonstrates the feasibility of stabilizing subunit vaccines using a spray-drying process and the suitability of the process for manufacturing a candidate product.

Similar content being viewed by others

Abbreviations

- DSC:

-

Differential scanning calorimetry

- HAI:

-

Hemagglutination inhibition

- KF:

-

Karl Fischer moisture content analysis

- mDSC:

-

Modulated differential scanning calorimetry

- PBS:

-

Phosphate-buffered saline

- PXRD:

-

Powder X-ray diffraction

- SEM:

-

Scanning electron microscopy

- SRID:

-

Single radial immunodiffusion

- Tg :

-

Glass transition temperature

- Tm :

-

Melting temperature

- ZBH:

-

Zero-background holder

REFERENCES

World Health Organization (WHO), United Nations Children’s Fund, World Bank. State of the world’s vaccines and immunization. 3rd ed. Geneva: WHO; 2009.

Wang W. Instability, stabilization, and formulation of liquid protein pharmaceuticals. Int J Pharm. 1999;185(2):129–88.

World Health Organization (WHO). Temperature sensitivity of vaccines. Geneva: WHO; 2006.

Wang W. Lyophilization and development of solid protein pharmaceuticals. Int J Pharm. 2000;203(1–2):1–60.

Saluja V, Hinrichs WL, Frijlink HW. Dried influenza vaccines: over the counter vaccines. Hum Vaccin. 2010;6(10):854–6.

Schlehubera L, McFadyena I, Yu S, Carignana J, Duprex WP, Forsyth WR, et al. Towards ambient temperature-stable vaccines: the identification of thermally stabilizing liquid formulations for measles virus using an innovative high-throughput infectivity assay. Vaccine. 2011;29(31):5031–9.

Chen D, Kristensen D. Opportunities and challenges of developing thermostable vaccines. Expert Rev Vaccines. 2009;8(5):547–57.

Kristensen D, Chen D, Cummings R. Vaccine stabilization: research, commercialization, and potential impact. Vaccine. 2011;29(41):7122–4.

Mustien JB, Lemon SM, Wright PF. Development of a more thermostable poliovirus vaccine. J Infect Dis. 1997;175 Suppl 1:S247–53.

Braun LJ, Jezek J, Peterson S, Tyagi A, Perkins S, Sylvester D, et al. Characterization of a thermostable hepatitis B vaccine formulation. Vaccine. 2009;27(34):4609–14.

Amorij JP, Huckriede A, Wilschut J, Frijlink HW, Hinrichs WL. Development of stable influenza vaccine powder formulations: challenges and possibilities. Pharm Res. 2008;25(6):1256–73.

Maa YF, Ameri M, Shu C, Payne LG, Chen D. Influenza vaccine powder formulation development: spray-freeze-drying and stability evaluation. J Pharm Sci. 2004;93(7):1912–23.

Seville PC, Li HY, Learoyd TP. Spray-dried powders for pulmonary drug delivery. Crit Rev Ther Drug Carrier Syst. 2007;24(4):307–60.

Cape SP, Villa JA, Huang ET, Yang TH, Carpenter JF, Sievers RE. Preparation of active proteins, vaccines and pharmaceuticals as fine powders using supercritical or near-critical fluids. Pharm Res. 2008;25(9):1967–90.

Jangle RD, Pisal SS. Vacuum foam drying: an alternative to lyophilization for biomolecule preservation. Indian J Pharm Sci. 2012;74(2):91–100.

Jin TH, Tsao E, Goudsmit J, Dheenadhayalan V, Sadoff J. Stabilizing formulations for inhalable powders of an adenovirus 35-vectored tuberculosis (TB) vaccine (AERAS-402). Vaccine. 2010;28(27):4369–75.

Chen D, Kapre S, Goel A, Suresh K, Beri S, Hickling J, et al. Thermostable formulations of a hepatitis B vaccine and a meningitis A polysaccharide conjugate vaccine produced by a spray drying method. Vaccine. 2010 Jul 12;28(31):5093–9.

Ohtake S, Martin RA, Yee L, Chen D, Kristensen D, Lechuga-Ballesteros D, et al. Heat-stable measles vaccine produced by spray drying. Vaccine. 2010;28(5):1275–84.

DuBose E, Settell D, Baumann J. Efficient scale-up strategy for spray-dried amorphous dispersions. Drug Dev Deliv. October 2013;13(8):54–62.

Shoji Y, Chichester JA, Jones M, Manceva SD, Damon E, Mett V, et al. Plant-based rapid production of recombinant subunit hemagglutinin vaccines targeting H1N1 and H5N1 influenza. Hum Vaccin. 2011;7(Suppl):41–50.

Shoji Y, Chichester JA, Bi H, Musiychuk K, de la Rosa P, Goldschmidt L, et al. Plant-expressed HA as a seasonal influenza vaccine candidate. Vaccine. 2008;26(23):2930–4.

Shoji Y, Farrance CE, Bautista J, Bi H, Musiychuk K, Horsey A, et al. A plant-based system for rapid production of influenza vaccine antigens. Influenza Other Respir Viruses. 2012;6(3):204–10.

Shoji Y, Jones MR, Mett V, Chichester JA, Musiychuck K, Sun X, et al. A plant-produced H1N1 trimeric hemagglutinin protects mice from a lethal influenza virus challenge. Hum Vaccin Immunother. 2013;9(3):553–60.

Iver V, Livanage MR, Shoji Y, Chichester JA, Jones RM, Yusibov V, et al. Formulation development of a plant-derived H1N1 influenza vaccine containing purified recombinant hemagglutinin antigen. Hum Vaccin Immunother. 2012;8(4):453–64.

Surawase RK, Surana SS, Maru AD, Malpure PS. Development of directly compressible co-excipient by spray drying technique. Int J Pharm Phytopharmacol Res. 2011;1(1):35–47.

Arakawa T, Ejima D, Tsumoto K, Obeyama N, Tanaka Y, Kita Y, et al. Suppression of protein interactions by arginine: a proposed mechanism of the arginine effects. Biophys Chem. 2007;127(1–2):1–8.

Roos YH. Importance of glass transition and water activity to spray-drying and stability of dairy powders. Lait. 2002;82:475–84.

Kaushik JK, Bhat R. Why is trehalose an exceptional protein stabilizer? An analysis of the thermal stability of proteins in the presence of the compatible osmolyte trehalose. J Biol Chem. 2003;278(29):26458–65.

Leslie SB, Israeli E, Lighthart B, Crowe JH. Trehalose and sucrose protect both membranes and proteins in intact bacteria during drying. Appl Environ Microbiol. 1995;61(10):3592–7.

ACKNOWLEDGMENTS AND DISCLOSURES

This work was supported with funding from the Defense Threat Reduction Agency. The authors wish to thank Patricia Logan, Amy Wales, and Marjorie Murray for their assistance in the development of this article, Megan Coffin and Dione Gray for their technical assistance with the immunogenicity studies, and Dr. John Sumida for the sample testing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, C., Shoji, Y., McCray, S. et al. Stabilization of HAC1 Influenza Vaccine by Spray Drying: Formulation Development and Process Scale-Up. Pharm Res 31, 3006–3018 (2014). https://doi.org/10.1007/s11095-014-1394-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-014-1394-3