Abstract

Online valve monitoring, also called “ValveWatch,” is a state-of-the-art method for improving the reliability of safety critical valves during operation. This well-known method has been used for almost two decades to reveal the possible failures of valves, actuators and control systems. This paper reviews some of the existing literature about ValveWatch technology to provide more detailed information about this online monitoring approach and its benefits. The possible causes and effects of failures associated with safety critical valves based on the existing literature are identified and summarized in this paper. Safety critical valves mainly include Emergency Shut Down and Process Shut Down (PSD) valves connected to Process Shut Down (PSD) systems. Three types of sensors that comprise part of the ValveWatch system will be identified and explained in this paper: the stain gauge, the dynamic pressure gauge and the static pressure gauge on the actuator. The function and logic of these three sensors are explained in this paper. All of the problems associated with valves, actuators and control system are identified and listed in a table and the probability of detecting these failures through visual inspection as well as online monitoring is assessed. A method of utilizing equations to calculate the probability of failure detection for valves, actuators, control system and the whole assembly through visual inspection as well as using sensors is developed. Additionally, the methodology given in functional safety and International Electrotechnical Commission 61,508 to calculate Diagnosis Coverage is used in this paper, and future research work to address condition monitoring for pressure safety valves and check valves is proposed. A Separate research is required to improve the reliability of the ValveWatch system.

Similar content being viewed by others

References

Offshore technology (2020). Piper Alpha Platform, North Sea [online] available at: https://www.offshore-technology.com/projects/piper-alpha-platform-north-sea/ Accessed: May 15 2020

Macleod F., Richardson S. (2020). Piper Alpha: The disaster in detail. The Chemical Engineer [online] available at:https://www.thechemicalengineer.com/features/piper-alpha-the-disaster-in-detail/ Accessed: 16 May 2020

Juvik T., Carr R., Hermansen T., Hale S. (2002). Online valve monitoring system used on off-shore platforms in the North Sea. 21st International Conference on Offshore Mechanics and Artic Engineering. ASME. Oslo, Norway. Paper No. OMAE2002–28403

Lemme, A., & Furseth, H. J. (2019). Expansion of the condition monitoring strategy for ESD and PSD valves on Johan Sverdrup phase 1- A case study in Equinor ASA. Faculty of science and technology: University of Stavanger.

Sotoodeh, K. (2019a). Safety integrity level in valves. Journal of Failure Analysis and Prevention Springer., 19, 832–837. https://doi.org/10.1007/s11668-019-00666-2

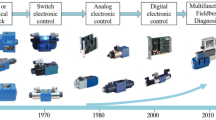

Sangolt J.K., Bjoroy M., Erstad T. (2019). Application of industry 4.0 concepts for increasing reliability of valves. Western Norway University of Applied Sciences. Department of mechanical and marine engineering.

Jeeves S. (2016). Valve monitoring across disciplines and operations. MRC Global. Valve World Conference Dusseldorf. Presentation # PV16035.

Norskolje., Gass. (2018). Norwegian Oil and Gas Association. Application of IEC 61508 and IEC 61511 in the Norwegian Petroleum Industry (Recommended SIL requirement). Rev. 03.

Automation Forum (2019). What is emergency shutdown system (ESD)? [online] available at: https://automationforum.in/t/what-is-emergency-shutdown-system-esd/5825 Accessed May 16 2020

Inst Tools (2020). What is emergency shutdown system (ESD)? [online] available at: https://instrumentationtools.com/emergency-shutdown-system/ Accessed May 16 2020

Inst Tools (2020). Difference between process shutdown and emergency shutdown. [online] available at: https://instrumentationtools.com/process-shutdown-and-emergency-shutdown/ Accessed May 17 2020

Sotoodeh, K. (2018). Why are butterfly valves a good alternative to ball valves for utility services in the offshore industry? American Journal of Industrial Engineering (AJIE)., 5(1), 36–40.

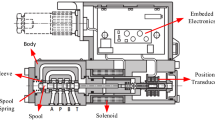

Sotoodeh, K. (2019b). Actuator selection and sizing for valves. Switzerland: Springer Nature.

MRC Global (2020). ValveWatch-Sensors. [online] available at: https://www.mrcglobal.com/Global-Region/Products/ValveWatch/Sensors Accessed May 17 2020

Sotoodeh, K. (2015). Packing solutions for butterfly valves in sea water services. Valve World Magazine., 20(9), 48–53.

Nesbitt, B. (2007). Handbook of Valves and Actuators Valves Manual International. London: Butterworth-Heinemann.

Sotoodeh K. (2018). Valve selection for bypass of control valves: A case study. [online] available at: https://www.valvemagazine.com/web-only/categories/technical-topics/9454-valve-selection-for-bypass-of-control-valves-a-case-study.html Accessed May 19 2020]

Sotoodeh, K. (2020a). Challenges associated with the bypass valves of control valves in sea water. Journal of marine science and application. https://doi.org/10.1007/s11804-020-00132-8

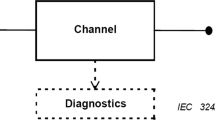

International Electrotechnical Commission (IEC), IEC 61508 (2010). functional safety of electrical/electronic/programmable electronic safety-related systems, Part 2: requirements for electrical/electronic/programmable electronic safety-related systems-, 2nd ed, Geneva.

American Petroleum Standard (API), API 6D (2015). Specification for pipeline and piping valve. 24th edition. Washington DC.

Sotoodeh, K. (2019c). The importance of maximum allowable stem torque in valves. Springer nature applied science. https://doi.org/10.1007/s42452-019-0445-0

SAE Aerospace Standard, SAE 4059 (2020). Aerospace fluid power—Cleanliness clarification for hydraulic fluids. USA.

Sotoodeh, K. (2019d). Valves and actuator integrity and blast load calculations. Springer nature applied science. https://doi.org/10.1007/s42452-019-0624-z

International Organization for Standardization (ISO) ISO 14313 2007 Pipeline transportation systems—pipeline valves 2 ISO Geneva

American Petroleum Institute (API) API 6DX (2012). Standard for actuator sizing and mounting kits for pipeline valves. 1st edition. API, Washington, DC

International Organization for Standardization (ISO) ISO 12490 (2011). Petroleum and natural gas industries—mechanical integrity and sizing of actuators and mounting kits for pipeline valves. 1st edition. Geneva.

Sotoodeh, K. (2020b). Optimized valve stem design in oil and gas industry to minimize major failures. Journal of failure analysis and prevention. https://doi.org/10.1007/s11668-020-00891-0

Emerson (2020). Electronically Enhanced Solenoid Technology. [online] available at: https://www.emerson.com/no-no/automation/solenoids-pneumatics/asco/solenoid-valve-technology Accessed May 23 2020

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sotoodeh, K. Development of a Numeric Method to Validate the Reliability Improvement of Safety Critical Valves During Operation Through Online Monitoring Implementation. Sens Imaging 21, 57 (2020). https://doi.org/10.1007/s11220-020-00323-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11220-020-00323-1