Abstract

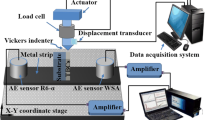

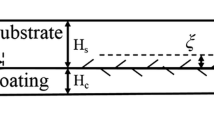

Calcium-magnesium-alumina-silicate (CMAS) corrosion has been regarded as the most important factor that leads to the degradation of thermal barrier coatings (TBCs). The failure mechanism of TBCs attacked by CMAS corrosion in the actual service conditions is still not clear due to the lack of an environmental simulator and nondestructive testing techniques. To solve the above problems, a real-time acoustic emission method combined with infrared thermography are developed to investigate the failure mechanism of TBCs attacked by CMAS corrosion. The results show that the acoustic emission signal spectrum only depends on the failure mode of the TBCs, and five failure modes are identified: surface vertical cracks, sliding interfacial cracks, opening interfacial cracks, substrate deformation and noise. The lifetime of TBCs attacked by CMAS corrosion is 40 thermal shock cycles, which is nearly six times lower than that of TBCs without CMAS corrosion (350 cycles). Conclusions: The failure mechanism of the former is interlaminar cracking and delamination in the ceramic coating; while that for the latter is interfacial delamination in the vicinity of thermal growth oxide.

Similar content being viewed by others

References

Padture NP, Maurice G, Jordan EH (2002) Thermal barrier coatings for gas-turbine engine applications. Science 296:280–284

Evans AG, Mumm DR, Hutchinson JW, Meier GH, Pettit FS (2001) Mechanisms controlling the durability of thermal barrier coatings. Prog Mater Sci 46:505–553

Zhu DM, Miller RA (2010) Development of advanced low conductivity thermal barrier coatings. Int J Appl Ceram Technol 1:86–94

Zhao M, Pan W, Wan C, Qu Z, Li Z, Yang J (2017) Defect engineering in development of low thermal conductivity materials: a review. J Eur Ceram Soc 37:1–13

Li G, Yang G (2019) Understanding of degradation-resistant behavior of nanostructured thermal barrier coatings with bimodal structure. J Mater Sci Technol 35:231–238

Wellman RG, Nicholls JR (2007) A review of the erosion of thermal barrier coatings. J Phys D Appl Phys 40:R293–R305

Rabiei A, Evans AG (2000) Failure mechanisms associated with the thermally grown oxide in plasma-sprayed thermal barrier coatings. Acta Mater 48:3963–3976

Borom MP, Johnson CA, Peluso LA (1996) Role of environment deposits and operating surface temperature in spallation of air plasma sprayed thermal barrier coatings. Surf Coat Technol 86–87:116–126

Levi CG, Hutchinson JW, Vidal-Sétif MH, Johnson CA (2012) Environmental degradation of thermal-barrier coatings by molten deposits. MRS Bull 37:932–941

Perepezko JH (2009) The hotter the engine, the better. Science 326:1068–1069

Wu J, Guo HB, Gao YZ, Gong SK (2011) Microstructure and thermo-physical properties of yttria stabilized zirconia coatings with CMAS deposits. J Eur Ceram Soc 31:1881–1888

Vidal-Setif MH, Chellah N, Rio C, Sanchez C, Lavigne O (2012) Calcium–magnesium–alumino-silicate (CMAS) degradation of EB-PVD thermal barrier coatings: characterization of CMAS damage on ex-service high pressure blade TBCs. Surf Coat Technol 208:39–45

Li L, Hitchman N, Knapp J (2009) Failure of thermal barrier coatings subjected to CMAS attack. J Therm Spray Technol 19:148–155

Li L, Clarke DR (2008) Effect of CMAS infiltration on radiative transport through an EB-PVD thermal barrier coating. Int J Appl Ceram Technol 5:278–288

Wellman R, Whitman G, Nicholls JR (2010) CMAS corrosion of EB PVD TBCs: identifying the minimum level to initiate damage. Int J Refract Met Hard Mater 28:124–132

Kakuda TR, Levi CG, Bennett TD (2015) The thermal behavior of CMAS-infiltrated thermal barrier coatings. Surf Coat Technol 272:350–356

Evans AG, Hutchinson JW (2007) The mechanics of coating delamination in thermal gradients. Surf Coat Technol 201:7905–7916

Troczynski T, Cockcroft S, Wong H (1996) Thermal barrier coatings for Heta engines. Key Eng Mater 122-124:451–462

Xia J, Yang L, Wu RT, Zhou YC, Zhang L, Huo KL, Gan M (2019) Degradation mechanisms of air plasma sprayed free-standing yttria-stabilized zirconia thermal barrier coatings exposed to volcanic ash. Appl Surf Sci 481:860–871

Drexler JM, Gledhill AD, Kentaro S, Vasiliev AL, Reddy KM, Sanjay S, Padture NP (2011) Jet engine coatings: jet engine coatings for resisting volcanic ash damage. Adv Mater 23:2388–2388

Drexler JM, Aygun A, Li D, Vaßen R, Steinke T, Padture NP (2010) Thermal-gradient testing of thermal barrier coatings under simultaneous attack by molten glassy deposits and its mitigation. Surf Coat Technol 204:2683–2688

Steinke T, Sebold D, Mack DE, Vaßen R, Stöver D (2010) A novel test approach for plasma-sprayed coatings tested simultaneously under CMAS and thermal gradient cycling conditions. Surf Coat Technol 205:2287–2295

Han Z, Xu B, Wang H, Zhou S (2007) A comparison of thermal shock behavior between currently plasma spray and supersonic plasma spray CeO2–Y2O3–ZrO2 graded thermal barrier coatings. Surf Coat Technol 201:5253–5256

Gok MG, Goller G (2017) Microstructural characterization of GZ/CYSZ thermal barrier coatings after thermal shock and CMAS+ hot corrosion test. J Eur Ceram Soc 37:2501–2508

Wu YN, Zhang G, Feng CZ, Zhang BC, Liang Y, Liu FJ (2001) Oxidation behavior of laser remelted plasma sprayed NiCrAlY and NiCrAlY-Al2O3 coatings. Surf Coat Technol 138:56–60

Wu YN, Qin M, Feng ZC, Liang Y, Sun C, Wang FH (2003) Improved oxidation resistance of NiCrAlY coatings. Mater Lett 57:2404–2408

Chen HC, Liu ZY, Chuang YC (1993) Degradation of plasma-sprayed alumina and zirconia coatings on stainless steel during thermal cycling and hot corrosion. Thin Solid Films 223(1):56–64

Krause AR, Senturk BS, Garces HF, Dwivedi G, Padture NP (2015) 2ZrO2· Y2O3 thermal barrier coatings resistant to degradation by molten CMAS: part I, optical basicity considerations and processing. J Am Ceram Soc 97:3943–3949

Mechnich P, Braue W, Schulz U (2011) High-temperature corrosion of EB-PVD yttria partially stabilized zirconia thermal barrier coatings with an artificial volcanic ash overlay. J Am Ceram Soc 94:925–931

Wang Y, Guo HB, Gong SK (2009) Thermal shock resistance and mechanical properties of La2Ce2O7 thermal barrier coatings with segmented structure. Ceram Int 35:2639–2644

Curry N, Tang Z, Markocsan N, Nylén P (2015) Influence of bond coat surface roughness on the structure of axial suspension plasma spray thermal barrier coatings—thermal and lifetime performance. Surf Coat Technol 268:15–23

Ahmadi-Pidani R, Shoja-Razavi R, Mozafarinia R, Jamali H (2012) Improving the thermal shock resistance of plasma sprayed CYSZ thermal barrier coatings by laser surface modification. Opt Lasers Eng 50:780–786

Yang L, Yang TT, Zhou YC, Wei YG, Wu RT, Wang NG (2016) Acoustic emission monitoring and damage mode discrimination of APS thermal barrier coatings under high temperature CMAS corrosion. Surf Coat Technol 304:272–282

Yang L, Kang HS, Zhou YC, He LM, Lu C (2014) Intelligent discrimination of failure modes in thermal barrier coatings: wavelet transform and neural network analysis of acoustic emission signals. Exp Mech 55:321–330

Yang L, Zhou YC, Lu C (2011) Damage evolution and rupture time prediction in thermal barrier coatings subjected to cyclic heating and cooling: an acoustic emission method. Acta Mater 59:6519–6529

Cernuschi F, Bison P, Marinetti S, Campagnoli E (2010) Thermal diffusivity measurement by thermographic technique for the non-destructive integrity assessment of TBCs coupons. Surf Coat Technol 205:498–505

Franke B, Sohn YH, Chen X, Price JR, Mutasim Z (2005) Monitoring damage evolution in thermal barrier coatings with thermal wave imaging. Surf Coat Technol 200:1292–1297

Yao WB, Dai CY, Mao WG, Lu C, Yang L, Zhou YC (2012) Acoustic emission analysis on tensile failure of air plasma-sprayed thermal barrier coatings. Surf Coat Technol 206:3803–3807

Yang L, Kang HS, Zhou YC, Zhu W, Cai CY, Lu C (2015) Frequency as a key parameter in discriminating the failure types of thermal barrier coatings: cluster analysis of acoustic emission signals. Surf Coat Technol 264:97–104

Kim EY, Lee YJ, Lee SK (2012) Heath monitoring of a glass transfer robot in the mass production line of liquid crystal display using abnormal operating sounds based on wavelet packet transform and artificial neural network. J Sound Vib 331:3412–3427

Khamedi R, Fallahi A, Refahi Oskouei A (2010) Effect of martensite phase volume fraction on acoustic emission signals using wavelet packet analysis during tensile loading of dual phase steels. Mater Des 31:2752–2759

Yang L, Yang J, Xia J, Zhu W, Zhou YC, Wei YG, Wu RT (2017) Characterization of the strain in the thermal barrier coatings caused by molten CaO-MgO-Al2O3-SiO2 using a digital image correlation technique. Surf Coat Technol 322:1–9

Lee KI, Wu LT, Wu RT, Xiao P (2014) Mechanisms and mitigation of volcanic ash attack on yttria stablized zirconia thermal barrier coatings. Surf Coat Technol 260:68–72

Zhang G, Fan X, Xu R, Su L, Wang TJ (2018) Transient thermal stress due to the penetration of calcium-magnesium-alumino-silicate in EB-PVD thermal barrier coating system. Ceram Int 44:12655–12663

Schweda M, Beck T, Offermann M, Singheiser L (2013) Thermographic analysis and modelling of the delamination crack growth in a thermal barrier coating on Fecralloy substrate. Surf Coat Technol 217:124–128

Cernuschi F, Capelli S, Bison P, Marinetti S, Lorenzoni L, Campagnoli E, Giolli C (2011) Non-destructive thermographic monitoring of crack evolution of thermal barrier coating coupons during cyclic oxidation aging. Acta Mater 59:6351–6361

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant Nos. 11890684, 51590891 and 51672233), the Foundation for Innovative Research Groups of Hunan Province (Grant No. 2020JJ10005) and the Outstanding Youth Science Foundation of Hunan Province (Grant No. 2020JJ30031).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, W., Li, Z.Y., Yang, L. et al. Real-time Detection of CMAS Corrosion Failure in APS Thermal Barrier Coatings Under Thermal Shock. Exp Mech 60, 775–785 (2020). https://doi.org/10.1007/s11340-020-00603-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-020-00603-7