Abstract

Easy availability, preparation technique, and economic value make calcium polysulphide (CaS x ) a very useful inorganic chemical for various field and industrial applications. In this article, disparate applications of CaS x solution have been reviewed to suggest potential and future consolidation. This article also encompasses the physiochemical properties and production of CaS x solution, with critical appraisal on research focusing on CaS x application in agriculture industries and removal of potentially toxic elements (PTEs) from the environment. The kinetics of CaS x , technical issues associated with optimization of its dosage and environmental fate is also discussed in detail. This study covers almost all of the peer-reviewed research that has been performed since 1914. Some of the critiques in this article include the lack of integration between the exposure effect and the efficiency of treatment method, effects of oxidizing environments on the long-term performance of CaS x solution, and kinetics of CaS x solution with the PTEs. The working model of CaS x with PTEs is still system dependent, and therefore cannot be used with other applications. The kinetics of CaS x is described in detail with various phase stoichiometric reactions. Environmental fate is discussed based on applications, government reports, peer-reviewed articles and kinetics of CaS x , which provides a clear picture of emerging contaminants in the environment in relation to the insect resistance and ecotoxicology. Real time, lab based research articles are needed to identify toxicity limits of CaS x in environment in order to describe its effective permissible limit in environmental system. This review article provides a risk assessment of environmental pollution by CaS x based on its physicochemical characteristic, stoichiometry, kinetics, field, and industrial applications.

Similar content being viewed by others

Introduction

Calcium polysulphide (CaS x ) (CAS no. 1344-81-6), also known as “calcium sulphide (CaS)” and “lime sulphur”, naturally occurs as gypsum (CaSO4·2H2O) or plaster of Paris (CaSO4.1/2H2O) (Knauf et al. 1973; Klein et al. 1985) in the environment. Under required conditions CaS x (x = 2–7) can be produced by oxidation of hydrogen sulphide (H2S) and calcium oxide (CaO) (density 2.61 g cm−3) (Borgwardt 1984). Levchenko et al. (2015) identified a semi-industrialized method to synthesize CaS x solution with a Ca/S ratio of 10:23.2 at 100 °C in 200 l of distilled water resulting in 70–75 % CaS x yield. CaS x is a dark orange solution with a volatile and unstable nature, especially if exposed to air (Chrysochoou and Ting 2011; Levchenko et al. 2015). CaS x molecules can exist as chains of heptasulphide, octasulphide, and nanosulphide species with a pH value ranging from 6.0 to 11.0 (Gun et al. 2004; Kamyshny et al. 2007a, b). This long chain tends to breakdown into shorter chains as the pH decreases (Chen and Morris 1972). CaS x solution contains only 10 % of elemental sulphur at pH 12.0 in the form of polysulphides (S6 and S5) (Chrysochoou et al. 2010). Other species of sulphur exist in the CaS x solution such as hydrosulphide (HS−), thiosulphate (S2O3 −), dithionate (S2O6 2−) and H2S (Yahikozawa et al. 1978; Kelsall and Thompson 1993). Some sulphur species like S5 2−, S4 2−, and H2S becomes the dominant species at pH values less than 8.0 (Kelsall and Thompson 1993; Chrysochoou et al. 2010).

CaS x solution has a strong reducing capability towards heavy metals and radionuclides and acts by making precipitates with insoluble metal in the form of their sulphides (Jacobs 2001; Zhong et al. 2009). The minimum purity of CaS x is between 290 and 320 g kg−1 required by EFSA with boiling point of 104.8 °C and solubility in water above pH 8.5 (EFSA 2010; Table 1). CaS x is also regarded as one of the most promising reductants, with field applications in soils and for chromite ore processing residue (COPR) (Storch et al. 2002; IETEG 2005; Charboneau et al. 2006; Wazna et al. 2007; Bewley and Clarke 2010).

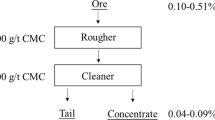

CaS x is used as “Liquid-Lime Sulfur” (LLS) (EPA reg. no. 66,196–2) in agriculture where a typical solution contains a mixture of 29 % (w/v) CaS x and small amounts of calcium thiosulfate (Smilanick and Sorenson 2001). LLS is prepared by the combination of hydrated lime (CaO·H2O) and elemental sulphur with water (Tartar 1914; Auld 1915).

The aim of this literature review is to combine all the available scientific papers on CaS x applications to provide a cross section of major research related to CaS x . The goal of this review is to summarize the physico-chemical properties of CaS x , its different applications, study its kinetics, and provide a critique on its environmental fate (Tables 1, 2, 3, and 4). The range of applications include metal and organic pollutant removal from the environment including air, water, soil, sediments, and COPR, which makes it an attractive chemical for research. The understanding of proper mechanism and kinetics of CaS x can provide help to researchers and stakeholders in its application. This review combines available scientific research and suggests the harmful effects of CaS x residues in the environment, which is commonly ignored by stakeholders.

Methods

This article covers peer-reviewed research papers, case studies, conference papers, and reports from EU government as well as United States Environmental Protection Agency (USEPA) dating as far back as 1914 to 2015. This review intends to combine standard techniques and methods published in peer-reviewed journals, summarize the supporting data from available research and present the findings in tabular form (Tables 1, 2, 3, and 4). The standard toxicity testing results from USEPA and European Food Safety Authority (EFSA) and the peer-reviewed articles were used to discuss environmental fate and risk assessment of CaS x (Table 4).

Applications of CaS x solution

Application of CaS x in agriculture

Since the nineteenth century, CaS x solution has been used to control fungus and molds (McCallan 1967; USEPA 2005; Table 2). More recently, CaS x solution was used as an active ingredient for insecticides in agricultural industries (Aratani et al. 1978b) and in the form of LLS for spraying trees, fruits, and rose bushes (Ganczarczyk et al. 1985). CaS x is known to reduce up to 80 and 70 % of the mold caused by Penicillium digitatum and Geotrichum citri-aurantii, respectively (Smilanick and Sorenson 2001). In a similar study by Palou et al. (2002), CaS x was studied with a range of other chemicals in order to select the most effective fungicide agent against P. digitatum or Penicillium italicum. The effectiveness of the selected chemicals was tested either alone or in mixtures at different temperatures. The results suggested that CaS x was more effective as a mixture of potassium sorbate (0.1 M) and sodium propionate (0.1 M) at pH 8.3 and potassium sorbate (0.1 M) and sodium acetate (0.1 M) at pH 7.0 compared to 8.5 M CaS x solution at 6.0 pH.

LLS is characterized by yellow-orange liquid, pH 11.5, with a density of 1.26 g mL−1 (Smilanick and Sorenson 2001). For a common recommended fungicide application, LLS solution is diluted to 3 % (w/v) at pH 10.0. The present lime sulphur formula was standardized in England and LLS was rediscovered in 1800 and applied as a pesticide spray in 1850 shortly after a fungi disease grape powdery mildew introduced from North America, devastate vineyards in Europe (Large 1940). By 1900, LLS was commonly used in California for apple scab, powdery mildew, San Jose scale, aphids, mites, brown rot of peaches, and other diseases (Tweedy 1967; Eckert and Eaks 1989). LLS was found highly active against the gray mite, Calacarus citrifolia in South Africa (Dippenaar 1958). At present, LLS is certified as an acceptable pesticide by most “organic” grower organizations and the United States Department of Agriculture (USDA). Reports of its applications as a control of postharvest diseases includes Thurston County review summary report (2012) by USEPA (2005). In this report, LLS was used as a fungicide-insecticide/miticide (spider mites) against Powdery mildew, anthracnose, and scab (USEPA 2005).

The mode of action is described as metabolism disruption and acts as a protectant by utilizing the fungicidal properties of elemental sulphur during its degradation (IUPAC 2009). Some studies suggest that LLS works by producing two toxic components, H2S and elemental Sulfur. H2S is an inhibitor of cytochrome oxidase and elemental Sulfur oxidizes cytochrome b to cytochrome c with a byproduct release of H2S (Smith et al. 1977; Dorman et al. 2002).

Among various energy metabolism enzymes, cytochrome oxidase also plays an important role in regulating xenobiotics in insects (Pant 1958). Smilanick and Sorenson (2001) reported, that LLS deposits on P. digitatum spores, even after repeated rinsing. This causes long-term sub-lethal growth inhibition by persistent residual deposits, suggesting that LLS works in a continuous persistent way to inhibit the growth of P. digitatum instead of killing them immediately. Haller (1952) reviewed, LLS use on stone fruit and found that applications before harvest substantially reduced the postharvest incidence of brown rot of peaches, caused by Monilinia fructicola. Poulos (1949) reported, postharvest applications of LLS to the peaches reduced postharvest brown rot incidence about 60 % without injury to the fruit. The LLS solution needs continuous maintenance and renewal because it is constantly releasing small amounts of H2S gas that acidifies the solution (Smilanick and Sorenson 2001; Hojjatie et al. 2011).

Application of CaS x for detoxification of organic compounds

Another application of CaS x is to remove polychlorinated organic compounds from fly ash (Tabata et al. 2013; Table 2). Fly ash can be produced by coal combustion in electricity generation process, flue gas treatment, and municipal and industrial waste incineration (Nriagu 1988; Sun et al. 2010; Kalogirou et al. 2010; Tabata et al. 2013). In a study by Tabata et al. (2013), aqueous mixture of calcium hydroxide (CaOH) and sulphur was used to reduce dioxin compounds such as polychlorinated dibenzo-p-dioxins (PCSDDs), polychlorinated dibenzofurans (PCDFs), and polychlorinated biphenyls (PCBs) generated from industrial and municipal waste incinerators. A rapid hydrodechlorination of chlorobenzene and PCBs derivatives has been reported after CaS x application. The study concluded that about 87 % of the PCDD/Fs and PCBs were decomposed and detoxified at temperature 150 °C with 30- to 60-min agitation.

Application of CaS x for detoxification of metals

Detoxification of Cr(VI)

Chromium is one of the toxic and carcinogenic heavy metals frequently detected in polluted areas with Cr metallurgy, leather tanning, and metal plating industrial facilities (Syracuse Research Corporation 1993; Katz and Salem 1994; Chen et al. 1996; Chandra et al. 1997). Chromium occurs in various oxidation states ranging from Cr (−II) to Cr(+VI) out of which Cr(VI) and Cr(III) are the most stable species in the environment (Zayed and Terry 2003). Cr(VI) is mobile in soils with acidic and alkaline pH (Adriano 1986). To remove Cr(VI) from polluted area, it is reduced to Cr(III) in the presence of various sulphides, ferrous iron and soil organic matter (Rai et al. 1989). CaS x has been used as a rapid reductant of soluble Cr(VI) to immobile Cr(III) and this reaction has been referred to as “geochemical fixation” (Fruchter 2002; Freedman et al. 2005).

Chyrosochoou et al. (2010) treated Cr(VI)-contaminated glacial soil from a Cr plating facility using 1× and 2× stoichiometric ration of CaS x and analyzed the resultant Cr(VI) with synthetic precipitation leaching procedure (SPLP) and micro X-ray fluorescence spectrometry (Micro-XRF). The pH of treated soil increased from 6.0 to 11.0 upon CaS x addition and returned to 8.0–8.5 after 1 year. This suggests that CaS x created an apparent Cr(VI) immobilization environment for the first 60 days of treatment which subsequently decreased the solubility of Cr(VI) for up to 1 year of monitoring. Similarly, studies reported, CaS x as an effective agent to reduce Cr(VI) to Cr(III) at a former wood treatment facility (Jacobs 2001; IETEG 2005). Storch et al. (2002) reported Cr(VI) reduction at a former chrome plating facility in Arizona using CaS x . One of the case studies at Morsen pond Culvert, MA, USA, suggests the successful application of CaS x to treat Cr in a railroad embarkment with Cr laden pigment. CaS x also applied in Hanford cite to remove Cr from soil (Chaboneau et al. 2006).

CaS x solution has been used for the treatment of wastewater, groundwater and effluents attributable to different industries containing high concentrations of toxic elements (Aratani et al. 1978a, 1978b; Yahikowaza et al. 1978; Takaoka and Ganczarczyk 1985; Messer et al. 2004; Chen et al. 2009; Table 2). CaS x removed Cr contamination by reducing Cr(VI) to Cr(III) within 30 min of CaS x treatment (Yahikozawa et al. 1978). Cr(III) can be precipitated at alkaline pH to Cr(OH)3 (Graham et al. 2006). CaS x solution also studied in relation to the treatment of Cr by ion-exchange method in waste brine solutions (Pakzadeh and Batista 2011). Authors concluded that a molar ratio of CaS x to Cr(VI) between 0.60 and 1.40 at pH range 8.00–10.30 is needed to obtain a final Cr concentration less than 5 mg l−1.

Messer et al. (2004) recommended CaS x as a permanent remediation technique for Cr(VI) fixation in soil (alluvial fan sediments) and groundwater, based on a study at a former metal plating facility in Western Arizona. In this study, approximately 660 gal of 29 % CaS x was applied to the 20-ft2 test zone of infiltration trenches for 24 h followed by 2500 gal of water to disperse the chemical through test zone. Results for the first 30 days indicated a 90 % reduction in Cr(VI) concentration. In the same study, authors applied approximately 9000 gal of 29 % CaS x in an aquifer at about 165 ft below the surface of the soil followed by 79,000 gal of water. In this case, less than 1 mg l−1 Cr(VI) was observed after 35 h of CaS x treatment.

There were attempts to treat groundwater contaminated with Cr(VI) in anaerobic conditions (Zhong et al. 2009). One study considered the foamability of CaS x and determined the reducing potential of CaS x when delivered as foam. CaS x was mixed with surfactant sodium POE(3) laureth sulphate, or sodium laurylether sulphate, to treat Cr(VI) in groundwater under anaerobic conditions. Delivery of CaS x as a foam was compared with the direct flushing of the CaS x solution. It was concluded that direct liquid flushing of CaS x solution was more effective than the delivery of CaS x foam (>98 % of total water leachable Cr(VI) was mobilized compared to 28 % mobilization, respectively). Another study reported the reduction of Cr(VI) in solution under anaerobic condition catalyzed with sulphur nanoparticles resulted in accelerated Cr(VI) reduction (Lan et al. 2005).

CaS x was also widely used as a strong reductant Cr(VI) to Cr(III) in COPR which is generated as a waste by-product during industrial chromite ore processing. COPR contains high amounts of Cr(VI) (Freese et al. 2014). CaS x is used for the treatment of COPR by reducing Cr(VI) to Cr(III) at variable pH (Lan et al. 2005; Graham et al. 2006; Farmer et al. 2006; Wazne et al. 2007; Moon et al. 2008, 2009; Chrysochoou et al. 2009a, 2009b, 2010; Jagupilla et al. 2009; Chrysochoou and Ting 2011; Freese et al. 2014). CaS x solution was directly applied on the COPR to treat the Cr(VI). The effect of the treatment was evaluated by measuring the resultant Cr(III) either quantitatively or qualitatively. In each of these studies, different molar ratios of CaS x solution to Cr(VI) were used under different pH conditions (Table 2). Graham et al. (2006) were first to use CaS x for the COPR treatment in Glasgow, UK, in groundwater contamination from the chemical works and suggested the pH range 8.0 to 12.5 was more effective.

CaS x requires suitable conditions to reduce Cr(VI) at different rates. COPR treatment is challenging in terms of speciation and distribution of Cr(VI) specially when Cr(VI) occurs in the solid phase. According to Chyrosochoou et al. (2009b) solid phase made Cr(VI) inaccessible for CaS x to bind. Therefore in order to react Cr(VI) with the added sulphur ions (CaS5), it is essential to release Cr(VI) from solid matrix into solution. Similarly, Cr(VI) was bounded as PbCrO4 in the beginning that precipitated in the interspatial pores of soil and had a long residence time in environment (Chyrosochoou et al. 2010). Authors also concluded that in situ reduction is not an efficient treatment method for high Cr(VI) containing soils in surficial layers. The CaS x application for Cr application has been summarized in Table 2.

Detoxification of other potentially toxic elements (PTEs)

Another application of CaS x is to remove PTEs from different matrices such as fly ash, soil, wastewater, and groundwater (Table 2). Fly ash generated from municipal waste incineration facilities contains high levels of pollutants like dioxins and heavy metals including Pb and Cr(VI) (Bosshard et al. 1996; Nagib and Inoue2000; Hartmut et al. 2001; Kalogirou et al. 2010; Darakas et al. 2013). In a study by Sun et al. (2010), the application of CaS x solution in fly ash precipitated Pb as PbO/PbCO3. It was concluded that there was an overall decrease in soluble Pb concentration from the leachates of treated fly ash by post-treatment leaching tests.

CaS x solution has also been used for the treatment of wastewater, groundwater and effluents attributable to different industries containing high concentrations of toxic elements (Aratani et al. 1978a, 1978b; Yahikowaza et al. 1978; Takaoka and Ganczarczyk1985; Messer et al. 2004; Chen et al. 2009; Table 2). Yahikowaza et al. (1978) utilized CaS x (x = 4.7–5.4) as a single coagulant, to remove heavy metals (Hg2+, Cd2+, Pb2+, Cu2+, Zn2+, Cr3+, and Cr6+) from wastewater. CaS x also used as a potential treatment of industrial effluents containing concentrated cyanide (CN) liquors in combination of other polysulphides (Takaoka and Ganczarczyk1985). The study suggested that the treatment was effective in a broad range of CN concentrations and metal complexes.

Calcium sulphide (CaS) was studied in relation to the sulphidation of Zn, Ni, and Cu from wastewater originating from a plating facility (Soya et al. 2010). In this study, selective precipitation of metal sulphides achieved at different pH values and CaS x was described as the most effective precipitation agent for separation and recovery of Cu, Zn, and Ni. Increasing the molar ratio of the filtrates resulted in increasing pH value. In another study, CaS x solution was used for the treatment of automotive wastewaters containing Cu, Ni, Pb, and Zn (Kim et al. 2002). In this case, precipitation of metals as sulphides were compared to metal hydroxide precipitation in the presence of chelating agents and it was concluded that the presence of small amounts of chelating agents can decrease the solubility of metal sulphides. Chelating agents, such as EDTA, can inhibit the precipitation of Ni, Zn and Pb above the proposed standards. In a study by Mihara et al. (2008), CaS was produced as a recycled product of waste gypsum. CaS was then used for treatment of Ni containing simulated wastewater. The produced CaS was utilized as a sulphuration agent to treat simulated wastewater containing Ni. CaS to Ni ratio of 1.30 was successfully decreased the concentration of Ni from 100 mg l−1 to less than 1.0 mg l−1 (Table 3).

CaS x is also used for demercurisation processes as patented by Russian institution. In this process, a mercury containing waste, phosphor (the content is Tuti was determined according to GOST C 51768–2001) was mixed in polyethylene containers with the sample oxidizer (chlorine, lime, white, chloramine). To obtain a thick concrete solution consistency, 25–50 wt% water was added to the mixture and left for 7–8 h. CaS x (2.5 to 12 %) was added to this mixture at room temperature and laid out on pallets for 2–2.5 h until it dried out. Analytical analyses demonstrated a significant reduction in Hg concentration (0.0022 mg/m3) (Patent RU(11) 2 400 545(13) C1).

Application for CaS x as nanoparticle

Advancing technology and increasing consumer demand resulted in the development of efficient and more effective chemicals in the form of nanoparticles. One such chemical is sulphur nanoparticles which can be prepared from aqueous solution of CaS x with hydrochloric, oxalic, nitric, and sulphuric acid (Massalomov et al. 2014). Sulfur nanoparticles produced by polysulphides resulted in high-efficiency fungicide and plant growth regulators (Massalimov et al. 2013, 2014). Nanoparticle preparation from aqueous solution of polysulphides of alkali and alkaline-earth metals is described simple and ecologically safe (Massalimov et al. 2012). It is also interesting to note that nanoparticles prepared from CaS x with a mixture of hydrazine hydrate and monoethanolamine resulted in an average particle size of 20–25 nm, which further coarsen to 100–1000 nm after 10–15 min (Massalimov et al. 2014).

Technical issues associated with the molar ratio of CaS x required for treatment of PTEs

The available literature where CaS x solution was applied for environmental remediation primarily comprises case studies involving the remediation of COPR and examined the kinetics of CaS x reaction in greater depth (Graham et al. 2006; Wazne et al. 2007; Moon et al. 2008; Tinjum et al. 2008). There was little insight into the mechanism of CaS x reactions with other PTEs. However, there have been empirical findings regarding the stoichiometric ratio of CaS x to PTEs for an effective removal of PTEs, especially for Cr(VI). The ratio of CaS x to Cr(VI) depends on many factors such as; type of matrices (soil, water, COPR, or sediments), concentration of PTEs, aerobic or anaerobic and the pH conditions. Most of the available literature working ratio of CaS x solution with PTEs and their methodological approaches has been summarized in Table 3.

Kinetics of CaS x

Kinetics of CaS x studied with methylation of polysulphide suggests the higher concentration of hepta- and octasulphides whereas, lower concentration of Nona-, deca- polysulphides (Kamyshny et al. 2004). Yahikozawa et al. (1978) studied the kinetics of CaS x in wastewater with the presence of heavy metals (Hg2+, Cd2+, Cu2+, Zn2+, and Cr6+), O2 and CO2. The simple reaction in the presence of O2 and CO2 is provided as:

Equation (2) suggests the presence of H2S in CO2 contained solution. CaS x decomposes rapidly in the presence of CO2 compared to O2 and produce H2S, CaCO3, CaSO4, and solid sulphur particles. In wastewater containing heavy metals, the precipitating reactions can be explained as:

Where;

M represents the heavy metal cations

MS represents the precipitated metal sulphides.

Hg removal from soil and other open surfaces described by a Russian patent (Patent RU(11) 2 400 545(13) C1) follows the following reaction without CO2 and O2:

According to the batch test experiment, Eq. (3) was found to be faster compared to equation (4). The precipitation rate was determined by the CaS x decomposition in former reactions (steps 1 and 2). The reactions from Eqs. 1 to 4 evolve with the formation of precipitate and known as “heterogeneous gas-liquid reaction”. Similarly Graham et al. (2006) suggested the following redox equilibrium reaction for COPR treatment using CaS x

Tabata et al. (2013) reported the mechanism based on hydrodechlorination in which they used CaS x to reduce fly ash waste. The authors postulated that Ca(OH) and sulphur reacted to produce CaS x . The CaS x solution decomposed to provide a mixture of Ca(SH)2, Ca(OH)2 and Ca(SH)(OH) in the presence of water, which further produces CaS and CaS x . The resultant CaS and CaS x acted as strong reducing agents in the reaction mixture and reduced chlorinated compound to CaSO4 or CaSO3.

Ganczarczyk et al. (1985) studied the thermodynamic reaction of CaS x conversion to CN, resulted in thiocyanate production. In this study, a rapid moderately exothermic reaction of CN with CaS x was detected, where CN concentration was non-detectable within 2 weeks. CaS x was used for phosphate removal by precipitating phosphate ions into calcium phosphate present in wastewater in the presence of calcium ions (Aratani et al. 1978b). Similarly, LLS solves the water contamination problem by forming irreversible and insoluble sulphide salts with Zn and Cu (Salvato1992).

The environmental fate and toxicity aspects of CaS x

CaS x has a very high pH (about 11.5 which is corrosive) and can cause irreversible eye damage (EPA Toxicity Category I) and is considered mildly irritating to skin (EPA Toxicity Category III) (USEPA2005). Chronic dietary toxicity hazard, carcinogenicity, and mutagenic content have not been identified so far (USEPA 2005). CaS x exposure to midge eggs caused embryogenesis although evaluation of the testing methods indicates that the response may not cause by the CaS x ; therefore, endocrine disruption needs further research (Thurston county report 2012). The primary safety hazards it poses include burns from skin or eye contact with concentrated solution, or from exposure to H2S gas that can evolve from LLS. Occupational health and safety administration workplace limits for H2S are 10 μl l−1 for 8 h and 15 μl l−1 for brief exposures of 15 min (Anon 1997).

As discussed earlier, CaS x is used widely as a pesticide and insecticide in agriculture industries. About 500,000 tons of insecticides are now applied each year in the USA alone and insects such as aphids continue to affect agricultural productivity by developing resistance against these chemicals (van Emden and Harrington 2007). Pesticide resistance is the adaptation of pest populations resulting in decreased susceptibility to that chemical. In other words, resistance is the key mode of survival which evolves over time and gets genetically passed on to the offspring (PBS 2001). Resistance can be developed in insects with time and continuous usage of particular chemical. After 100 years of LLS usage, Melander (1914) reported orchard pests, the San Jose scale (Quadraspidiotus perniciousus) in the state of Washington, developed resistance to LLS on various in situ experiments. In the first experiment, all scales were killed with lime treatment within 1 week in typical orchards. However, the survival rate increased to 90 % after 2 weeks in an orchard with resistant scales. In a second experiment, the author used 2° (1 lb.: 7 gal), 3° (1 lb.: 5 gal), 5° (4 × 3°), 1:1/2:5, 1:2:5 factory made sulphur-lime in Clarkston, Walla Walla, Kennewick, Prosser, Sunnyside, North Yakima, and Wenatchee, USA, to carry out experiments with 350,000-scale insects. In a biweekly experiment, he found 50 % of the scales were still alive under the crust of dried spray. LLS also reported damage to fruit quality as well as reduced the number of harvested fruits with increasing application due to its sulphide content (Palmer et al. 2003). Authors reported a delay of maturity and fading of colors in apples treated with 12 % lime sulphur as well as decreased photosynthesis activity in plants.

Another application of CaS x is metal binding which makes it attractive for cleaning contaminants from wastewater and groundwater facilities. However, water based CaS x applications are not suitable for deep vadose zones and can lead to groundwater contamination by mobilizing the contaminant through preferential pathways within the sediments (Dresel et al. 2011). The Deep Vadose region is a zone of low permeability, having preferential flow area that is determined by gravity (Zhong et al. 2009).

Maletić et al. (2015) used many ameliorants to treat metal-contaminated soils, where CaS x solution was one of the ameliorants tested for its toxicity. The toxicity test was performed on the extracted pore water samples after treatment with different doses of CaS x solutions. For this purpose, a genetically modified lux-based biosensor: Escherichia coli HB101 (pUCD607) was used in a dose-response manner. The luminescence was measured after 15-min exposure. It was concluded that CaS x solution outperformed the other ameliorants. Furthermore, CaS x demonstrated the least toxic response as measured by the biosensor compared to other ameliorants studied (namely bone meal, activated carbon, and bentonite). Similarly, Bailey et al. (2012) exposed microbes, Shewanella oneidensis MR-1 to CaS x and other surfactants (sodium laureth sulphate (SLES), sodium dodecyl sulphate (SDS), cocamidopropyl betaine (CAPB), and NINOL40-CO). CaS x was found to be toxic at all the tested concentration (1.45–7.25 mM) and stimulatory at lower concentrations (20–500 μM). Most of the standard toxicity tests performed by IUPAC and USEPA used the LLS form. LLS demonstrated moderate acute toxicity in mammals, fish, and aquatic invertebrates and low acute toxicity in insects (Anon 1997; IUPAC 2009). Combined data with organisms is summarized in Table 4.

Conclusion

CaS x is an inorganic chemical that gained popularity in agricultural industries due to its effective insecticide and pesticide properties. It is most commonly used in the form of LLS and applied towards post-harvest treatments. With increasing application, recent technologies has developed sulphur nanoparticles from CaS x , which demonstrated a higher efficiency and improved regulation in plant growth. Although increasing use of any chemical can cause resistance issues in insects, limited research is available, making it difficult to identify the insect species which have developed resistance and the amount needed for successful application. There is a need of experimental series describing ecological issues regarding LLS for the effective measurements.

CaS x chemical properties to clean air, water, and soil pollution make it a prominent chemical in treatment of wastewater, groundwater and superfund sites. Its easy availability, economic cost, and successful application also adds value towards its industrial applications (Kameshwari et al. 2015). The hydrophobic nature of CaS x makes it a very applicable coagulant against heavy metal pollution from the environment. The kinetics demonstrated that the mode of action highly depends on pH, its physical state, and accessibility. The ability of CaS x to react with other metals and make them less soluble, nontoxic sulphides and hydroxides made it an approved reductant to clean contaminated land, wastewater, and groundwater (Jacobs 2001; Lewis 2011).

While a range of PTEs such as Zn, Pb, Fe, and Ni can be treated with CaS x ; however, its area of major application is Cr(VI) removal from groundwater, wastewater, soil, and COPR sources. CaS x is very effective and economically feasible to remove Cr(VI), which makes it popular in Cr plating and metallurgy industries. It works by precipitating heavy metals at certain basic pH. According to the literature reviewed so far, the chemical nature of CaS x makes it a very applicable chemical against of heavy metal pollution in the environment. Further successful applications in different industries can be identified by kinetics described within this paper.

Even after a range of use and application of CaS x , their molar ratio, dosage, and required chemical properties to work effectively is not very well defined. The successful application at defined pH is also missing in various prominent researches (Table 2). Limited stoichiometry data and kinetics with each metal makes it hard to implement its successful application with various heavy metals.

The limited research on the fate of CaS x in environment makes it a threat to living biota. Some government reports and peer-reviewed articles identified CaS x toxicity in various biota at certain quantity (Table 4), which requires attention and further studies. The lack of toxicity information cannot be compensated by field application and limited database reports by individual agency. The physiochemical properties of every single organism are different and highly depend upon their surrounding environment. Real-time lab experiments are necessary to identify its effects on living organisms in soil and water. Dietary as well as exposure experiments with organisms are required to define LC50 and LD50 values in living organisms.

CaS x application ranges from agriculture, metal refineries, leather tanning to construction industries. The wide range applications further expose it to the environment. So far, there is no documented human health effects associated with CaS x , which makes it an ecofriendly chemical against heavy metal pollution and other industrial application. However, there is a need to conduct some in depth studies related to the toxicity and resistance to avoid any future health and environmental hazards.

References

Adriano DC (1986) Trace elements in the environment. Chapter 5: chromium. Springer Verlag, New York

Anonymous (1997) National Institute for Occupational Safety and Health pocket guide to chemical hazards. US Department of human health services (NIOSH) publication no. 97–140. US Government Printing Office, Washington DC

Aratani T, Yahikozawa K, Matoba H, Yasuhara S, Yano T (1978a) Conditions for the precipitation of heavy metals from wastewater by the lime sulfureted solution (calcium polysulfide) process. Bull Chem Soc Jpn 51:1755–1760

Aratani T, Yasuyuki N, Matoba H, Yasuhara S, Yano T (1978b) The removal of heavy metals, phosphate, and COD substances from wastewater by the lime sulfureted solution (calcium polysulfide) process. Bull Chem Soc Jpn 51(9):2705–2709

Auld SJM (1915) LVII.—the reaction between calcium hydroxide and sulphur in aqueous solution. J Chem Soc Trans 107:480–495

Bailey KL, Tilton F, Jansik DP, Ergas SJ, Marshall MJ, Miracle AL, Wellman DM (2012) Growth inhibition and stimulation of Shewanella oneidensis MR-1 by surfactants and calcium polysulfide. Ecotoxicol Environ Safety 80:195–202

Bewley RJF, Clarke S (2010) Field application of calcium polysulphide for ex situ treatment of soils contaminated with chromite ore processing residue. Land Contam Reclam 18:1–12

Borgwardt RH (1984) Surface area of calcium oxide and kinetics of calcium sulphide formation. Environ Prog 3(2):129–135

Bosshard PP, Bachofen R, Brandl H (1996) Metal leaching of fly ash from municipal waste incineration by Aspergillus niger. Environ. Sci. Technol. 30(10):3066–3070

Chandra P, Sinha S, Rai UN (1997) Bioremediation of Cr from water and soil by vascular aquatic plants. In: Kruger EL, Anderson TA, Coats JR (eds) Phytoremediation of soil and water contaminants, ACS Symposium Series #664. American Chemical Society, Washington DC, pp. 274–282

Charboneau, B., Thomson, K.M., Wilde, R., Ford, B., Gerber, M. 2006 Hanford groundwater remediation. In: Proceedings of the WM’06 Conference, Tuscon, AZ, February 26–March 2

Chen K, Morris J (1972) Kinetics of oxidation of aqueous sulfide by O2. Environ Sci Technol 6(6):529–537

Chen A, Qiu X, Sridharan K, Horne WG, Dodd RA, Hamdi AH, Elmoursi AA, Malaczynski GW (1996) Chromium plating pollution sources reduction by plasma source ion implantation. Surf Coat Tech 82:305–310

Chen Q, Luo Z, Hills C, Xue G, Tyrer M (2009) Precipitation of heavy metals from wastewater using simulated flue gas: sequent additions of fly ash, lime and carbon dioxide. Water Res 43(10):2605–2614

Chrysochoou M, Johnston CP (2015) Polysulfide speciation and reactivity in chromate-contaminated soil. J Hazard Mater 281:87–94

Chrysochoou M, Ting A (2011) A kinetic study of Cr(VI) reduction by calcium polysulfide. Sci Total Environ 409(19):4072–4077

Chrysochoou M, Fakra SC, Marcus MA, Deok HM, Dermatas D (2009a) Microstructural analyses of Cr(VI) speciation in chromite ore processing residue (COPR). Environ Sci Technol 43(14):5461–5466

Chrysochoou M, Moon DH, Fakra S, Marcus M, Dermatas D, Christodoulatos C (2009b) Use of micro X-ray absorption spectroscopy and diffraction to delineate Cr(VI) speciation in COPR. Global Nest J 11(3):318–324

Chrysochoou M, Ferreira DR, Johnston CP (2010) Calcium polysulfide treatment of Cr(VI)-contaminated soil. J Hazard Mater 179(1–3):650–657

Chrysochoou M, Johnston CP, Dahal G (2012) A comparative evaluation of hexavalent chromium treatment in contaminated soil by calcium polysulfide and green-tea nanoscale zero-valent iron. J Hazard Mater 201-202:33–42.199

Darakas E, Tsiridis V, Petala M, Kungolos A (2013) Hexavalent chromium release from lignite fly ash and related ecotoxic effects. J Environ Sci Heal A 48(11):1390–1398

Dippenaar BJ (1958) Concentric ring blotch citrus. Its cause and control. S Afri J Agric Sci 1:83–99

Dorman DC, Moulin FJ-M, McManus BE, Mahle KC, James RA, Struve MF (2002) Cytochrome oxidase inhibition induced by acute hydrogen sulfide inhalation: correlation with tissue sulfide concentrations in the rat brain, liver, lung, and nasal epithelium. Toxicol Sci 65(1):18–25

Dresel PE, Wellman DM, Cantrell KJ, Truext MJ (2011) Review: technical land policy challenges in deep vadose zone remediation of metals and radionuclides. Environ. Sci. Technol. 42:4207–4216

Eckert JW, Eaks IL (1989) Postharvest disorders and diseases of citrus fruits. In: Reuther W, Calavan EC, Carman GE (eds) The citrus industry, vol 4. University of California Press, Berkeley, CA, pp. 179–260

EFSA (European Food Safety Authority) (2010) Conclusion on the peer review of the pesticide risk assessment of the active substance lime sulfur. EFSA J 8(11):1890–1935

Elesin MA, Pavlov AV, Berdov GI, Mashkin NA, Oglezneva IM (2002) Mechanism of hydration conversion of portland cement in calcium polysulfide solution. Russ J Appl Chem 75(6):883–887

Farmer JG, Paterson E, Bewley RJF, Geelhoed JS, Hillier S, Meeussen JCL, Lumsdon DG, Thomas RP, Graham MC (2006) The implications of integrated assessment and modelling studies for the future remediation of chromite ore processing residue disposal sites. Sci Total Environ 360(1–3):90–97

Freedman DL, Lehmicke L, Verce MF (2005) Reductive dechlorination of tetrachloroethene following abiotic versus biotic reduction of hexavalent chromium. Bioremediation Journal 9(2):87–97

Freese K, Miller R, Cutright TJ, Senko J (2014) Review of chromite ore processing residue (COPR): past practices, environmental impact and potential remediation methods. Current Environ Eng 1:82–90

Fruchter J (2002) In-situ treatment of chromium-contaminated groundwater. Environ. Sci. Technol. 36(23):464A–472A

Ganczarczyk JJ, Takoaka PT, Ohashi DA (1985) Application of polysulfide for pretreatment of spent cyanide liquors. Water Pollut Control Federation 57(11):1089–1093

Graham MC, Farmer JG, Anderson P, Paterson E, Hillier S, Lumsdon DG (2006) Calcium polysulfide remediation of hexavalent chromium contamination from chromite ore processing residue. Sci Total Environ 364(1–3):32–44

Gun J, Modestov A, Kamyshny A, Ryzkov D, Gitis V, Goifman A (2004) Electrospray ionization mass spectrometric analysis of aqueous polysulfide solutions. Microchim Acta 146:229–237

Haller MH (1952) Handling, transportation, storage, and marketing of peaches. USDA Biograph Bull 21:1–105

Hartmut M, Baumann W, Becker B, Jay K, Paur H-R, Seifert H (2001) Adsorption of PCDD/F on MWI fly ash. Chemosphere 42:803–809

Hojjatie, M., Feinstein, Y., Lockhart, C.L.F. 2011. Tessenderlo Kerley, Inc. US patent no. US034318 B1/US20110262343 A1, Washington DC.

IETEG (Independent Environmental Technical Evaluation Group) 2005 In: Guertin J, Jacobs, JAC Avakian (Eds.), Chromium(VI) Handbook, CRC Press, Boca Raton, FL

IUPAC (International Union of Pure & Applied Chemistry) 2015. Pesticide Properties Database. Lime sulphur. EC Regulation 1107/2009 (repealing 91/414). Accessed 11/16/2015.

Jacobs, J.A., 2001. In-situ delivery methods for remediation of hexavalent chromium in soil and groundwater. Abstracts of the national meeting of the national association of engineering geologists and American institute of professional geologists, St Louis, MO; Oct 5.

Jagupilla SC, Moon DH, Wazne M, Christodoulatos C, Kim MG (2009) Effects of particle size and acid addition on the remediation of chromite ore processing residue using ferrous sulfate. J Hazard Mater 168:121–128

Kalogirou, E., Themelis, N., Samaras, P., Karagiannidis, A., Kontogianni, ST., 2010. Fly ash characteristics from waste-to-energy facilities and processes for ash stabilization. ISWA World Congress 2010, Hamburg , Germany, 15–18 November 2010

Kameshwari KSB, Pedaballe V, Narasimman LM, Kalyanaraman C (2014) Remediation of chromite ore processing residue using solidification and stabilization process. Environ Prog Sustain Energy 34:674–680

Kameshwari KSB, Narasimman LM, Pedaballe V, Kalyanaraman C (2015) Diffusion and leachability index studies on stabilization of chromium contaminated soil using fly ash. J Hazard Mater 297:52–58

Kamyshny AJ, Goifman A, Gun J, Rizkov D, Ovadia L (2004) Equilibrium distribution of polysulfide ions in aqueous solutions at 25 °C: a new approach for the study of polysulfides’ equilibria. Environ. Sci. Technol. 38:6633–6644

Kamyshny A, Gun J, Rikzov D, Voitsekovski T, Lev O (2007a) Equilibrium distribution of polysulfide ions in aqueous solutions at different temperatures by rapid single phase derivatization. Environ. Sci. Technol. 41:2395–2400

Kamyshny A, Gun J, Rizkov D, Voitsekovski T, Lev O (2007b) Equilibrium distribution of polysulfide ions in aqueous solutions at different temperatures by rapid single phase derivatization. Environ Sci Technol 41:2395–2400

Katz SA, Salem H (1994) The biological and environmental chemistry of chromium. VCH Publishers, Inc., New York

Kelsall GH, Thompson I (1993) Redox chemistry of H2S oxidation by the British gas Stretford process, part II: electrochemical behavior of aqueous hydrosulphide (HS−) solutions. J Appl Electrochem 23:287–295

Kim BR, Gaines WA, Szafranski MJ, Bernath EF, Miles AM (2002) Removal of heavy metals from automotive wastewater by sulfide preparation. J Environ Eng 128(7):612–623

Klein, C., Hurlbut, C. S., Jr. 1985. Manual of mineralogy (20th edn.), John Wiley, pp. 352–353, ISBN 0–471–80580-7

Knauf, A., Hartmann, P., Schmidt, A., Wirsching, F., 1973. Process for treating plaster of paris. US patent Publication number: US3770468 A, Washington DC.

Lan Y, Deng B, Kim C, Thornton EC, Xu H (2005) Catalysis of elemental sulfur nanoparticles on chromium (VI) reduction by sulfide under anaerobic conditions. Environ Sci Echnol 39(7):207–2094

Large EC (1940) The advance of fungi. Dover, New York

Levchenko LM, Galitskii AA, Kosenko VV, Sagidullin AK (2015) Development of semi-industrial synthesis of calcium polysulfide solution and determination of the content of sulfide ions in solution. Russian J Appl Chem 88(9):1403–1408

Lewis M, Pryor R, Wilking L (2011) Fate and effects of anthropogenic chemicals in mangrove ecosystem: a review. Environ Pollut 159:2328–2346

Maletić SP, Watson MA, Dehlawi S, Diplock EE, Mardlin D, Paton GI (2015) Deployment of microbial biosensors to assess the performance of ameliorants in metal-contaminated soils. Water Air Soil Pollut 226:85

Massalimov IA, Gazizyanovich MA, Rifhatovn SA, Nailevich KA, Maratovna ZR (2012) Obtaining sulfur nanoparticles from sodium polysulfide aqueous solution. J Chem Chem Eng 6:233–341

Massalimov IA, Yanakhmetov MR, Chuykin AE, Mustafin AG (2013) Protection of building constructions with sulfur impregnating solution. Int J Sci 2:25–30

Massalimov IA, Khusainov AN, Zainitdinova RM, Musavirova LR, Zaripova LR, Mustafin AG (2014) Chemical precipitation of sulfur nanoparticles from aqueous solutions. Russ J Appl Chem 87(6):700–708

McCallan SEA (1967) History of fungicides. In: Torgeson DC (ed) Fungicides: an advanced treatise. 1 Academic Press, New York, pp. 1–37

Melander AL (1914) Can insects become resistant to sprays? J Econ Entomol 7:167–173

Messer, A., Storch, P, Palmer, D. 2004 In-situ remediation of chromium contaminated site using calcium polysulfide. Internal report. URS Corporation

Mihara N, Soya K, Kuchar D, Fukuta T, Matsuda H (2008) Utilisation of calcium sulfide derived from waste gypsum board for metal containing wastewater treatment. Global NEST J 10:101–107

Moon DH, Wazne M, Jagupilla SC, Christodoulatos C, Kim MG, Koutsospyros A (2008) Particle size and pH effects on remediation of chromite ore processing residue (COPR) using calcium polysulfide (CaS5). Sci Total Environ 399:2–10

Moon DH, Wazne M, Koutsospyros A, Christodoulatos C, Gevgilili H, Malik M, Kalyon DM (2009) Evaluation of the treatment of chromite ore processing residue by ferrous sulfate and asphalt. J Hazard Mater 166(1):27–32

Nagib S, Inoue K (2000) Recovery of lead and zinc from fly ash generated from municipal incineration plants by means of acid and/or alkaline leaching. Hydrometallurgy 56(3):269–292

Nriagu JO, Nieboer E (eds) (1988) Chromium in natural and human environments. Wiley Interscience, New York, pp. 81–104

Pakzadeh B, Batista JR (2011) Chromium removal from ion-exchange waste brines with calcium polysulfide. Water Res 45:3055–3064

Palmer JW, Davies SB, Shaw PW, Wünsche JN (2003) Growth and fruit quality of “Braeburn” apple (Malus domestica) trees as influenced by fungicide programs suitable for organic production. New Zeal Crop Hort 31:169–177

Palou L, Usall J, Smilanick J, Aguilar M, Vinas I (2002) Evaluation of food additives and low-toxicity compounds as alternative chemical for the control of Penicillium digitatum and Penecillium italicum on citrus fruit. Pest Manag Sci 58:459–466

Pant, C.P. (1958) “Studies on the mode of action of insecticides”. Retrospective Theses and Dissertations. Paper 2262.

Patent RU(11) 2 400 545(13) C1; Date of publication: 27.09.2010 Bull. 27. Method for demercuration of mercury-containing wastes for recycling said wastes.

PBS, 2001. Pesticide resistance. Retrieved on December 06, 2015.

Poulos PL (1949) The use of sodium hypochlorite for the control of the brown rot disease of peach in Delaware. Plant Dis Rep 33:413–415

Rai D, Eary LE, Zachara JM (1989) Environmental chemistry of chromium. Sci Tot Environ 86:15–23

Salvato JA (1992) Environmental engineering and sanitation, 4th edn. Wiley-Interscience, New York

Smilanick JL, Sorenson D (2001) Control of postharvest decay of citrus fruit with calcium polysulfide. Postharvest Biol Technol 21:157–168

Smith L, Kruszyna H, Smith RP (1977) The effect of methemoglobin on the inhibition of cytochrome c oxidase by cyanide, sulfide and azide. Biochem Pharmacol 26:2247–2250

Soya K, Mihara N, Kuchar D, Khbota M, Matsuda H, Fukuta T (2010) Selective sulfidation of copper, zinc and nickel in plating wastewater using calcium sulfide. Int J Civil Env Engg 2:93–97

Storch P, Messer A, Palmer D, Pyrih R (2002) Pilot test for in situ geochemical fixation of chromium (VI) using calcium polysulfide, in: proceedings of the third international conference on remediation of chlorinated and recalcitrant compounds. Battelle Press, Monterey, CA

Sun Y, Watanabe N, Qiao W, Gao X, Wang W, Zhu T (2010) Polysulfide as a novel chemical agent to solidify/stabilize lead in fly ash from municipal solid waste incineration. Chemospeher 81:120–126

Syracuse Research Corporation, 1993. Toxicological profile for chromium. Prepared for U.S. Dept. Health and Human Services, Public Health Service, Agency for Toxic Substances and Disease Registry, under Contract No. 205–88-0608.

Tabata M, Ghaffar A, Shono A, Notomi K (2013) Hydrodechlorination/detoxification of PCDDs, PCDFs, and co-PCBs in fly ash by using calcium polysulfide. Waste Manag 33:356–362

Takaoka PT, Ganczarczyk JJ (1985) Feasibility of polysulfide detoxification of concentrated cyanide waste-water. Water Pollut Res J Can 20(1):118–128

Tartar HV (1914) The reaction between Sulphur and calcium hydroxide in aqueous solution. J Am Chem Soc 36(3):495–498

Thurston County Review, 2012. Lime sulphur (calcium polysulphide). CAS #: 1344–81-6.

Tinjum JM, Benson CH, Edil TB (2008) Treatment of Cr (VI) in COPR using ferrous sulfate-sulfuric acid or cationic polysulfides. J Geotech Geoenviron Eng 134(12):1791–1803

Tweedy BG (1967) Elemental sulfur. In: Torgeson DC (ed) Fungicides: an advanced treatise, vol 2. Academic Press, New York, pp. 119–145

USEPA. Office of Prevention, Pesticides and Other Toxic Substances. Reregistration eligibility decision for inorganic polysulfides. List D—case no. 4054. September 30, 2005.

Van Emden H, Harrington R (eds) (2007) Aphids as crop pests. CABI, Wallingford, Oxon, GBR

Wazne M, Jagupilla SC, Moon DH, Christodoulatos C, Kim MG (2007) Assessment of calcium polysulfide for the remediation of hexavalent chromium in chromite ore processing residue (COPR). J Hazard Mater 143:620–628

Wazne M, Jagupilla SC, Moon DH, Christodoulatos C, Koutsospyros A (2008) Leaching mechanisms of Cr(VI) from chromite ore processing residue. J Environ Qual 37(6):2125–2134

Yahikozawa K, Aratani T, Ito R, Sudo T, Yano T (1978) Kinetic studies on the lime sulfureted solution (calcium polysulphide) process for the removal of heavy metals from wastewater. Bull Chem Soc Jap 51(2):613–617

Zayed AM, Terry N (2003) Chromium in the environment: factors affecting biological remediation. Plant Soil 249:139–156

Zhong L, Qafoku NP, Szecsody JE, Dresel PE, Zhang ZF (2009) Foam delivery of calcium polysulfide to the vadose zone for chromium(VI) immobilization: a laboratory evaluation. Vadose Zone J 8(4):976–985

Acknowledgment

Authors would like to thanks University of Dammam for its support. Authors also like to thanks Miss Kelly Corriea for her suggestions in this review article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Disclaimer

The views expressed in this paper are those of the authors and do not necessarily reflect the views or policies of any government organization and peer-reviewed research article authors.

Additional information

Responsible editor: Philippe Garrigues

Highlights

• Physicochemical properties of CaS x and its chemical speciation.

• Application of CaS x in agriculture industries, removal of potentially toxic elements (PTEs) from air, soil, wastewater, and groundwater.

• Reduction of Cr(VI) to Cr(III) in chromite ore processing residue (COPR).

• Technical issues associated with the molar ration of CaS x.

• Detailed kinetics of CaS x .

• Environmental fate and toxicity aspects of CaS x .

Rights and permissions

About this article

Cite this article

Dahlawi, S., Siddiqui, S. Calcium polysulphide, its applications and emerging risk of environmental pollution—a review article. Environ Sci Pollut Res 24, 92–102 (2017). https://doi.org/10.1007/s11356-016-7842-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-016-7842-3