Abstract

Background, aim, and scope

A coupled Life Cycle Costing and life cycle assessment has been performed for car-bodies of the Korean Tilting Train eXpress (TTX) project using European and Korean databases, with the objective of assessing environmental and cost performance to aid materials and process selection. More specifically, the potential of polymer composite car-body structures for the Korean Tilting Train eXpress (TTX) has been investigated.

Materials and methods

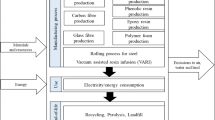

This assessment includes the cost of both carriage manufacturing and use phases, coupled with the life cycle environmental impacts of all stages from raw material production, through carriage manufacture and use, to end-of-life scenarios. Metallic carriages were compared with two composite options: hybrid steel-composite and full-composite carriages. The total planned production for this regional Korean train was 440 cars, with an annual production volume of 80 cars.

Results and discussion

The coupled analyses were used to generate plots of cost versus energy consumption and environmental impacts. The results show that the raw material and manufacturing phase costs are approximately half of the total life cycle costs, whilst their environmental impact is relatively insignificant (3–8%). The use phase of the car-body has the largest environmental impact for all scenarios, with near negligible contributions from the other phases. Since steel rail carriages weigh more (27–51%), the use phase cost is correspondingly higher, resulting in both the greatest environmental impact and the highest life cycle cost. Compared to the steel scenario, the hybrid composite variant has a lower life cycle cost (16%) and a lower environmental impact (26%). Though the full composite rail carriage may have the highest manufacturing cost, it results in the lowest total life cycle costs and lowest environmental impacts.

Conclusions and recommendations

This coupled cost and life cycle assessment showed that the full composite variant was the optimum solution. This case study showed that coupling of technical cost models with life cycle assessment offers an efficient route to accurately evaluate economic and environmental performance in a consistent way.

Similar content being viewed by others

References

Althaus H-J, Blaser S, Classen M, Jungbluth N (2003) Life Cycle Inventories of Metals. Final report ecoinvent 2000 No. 10. EMPA Dübendorf, Swiss Centre for Life Cycle Inventories, Dübendorf.

Bage G, Samson R (2003) The Econo-Environmental Return (EER). A Link between environmental impacts and economic aspects in a life cycle thinking perspective. Int J Life Cycle Assess 8(4):246–51

Bartlett N (2000) Trains in the 21st century. Design News, 4.1.2000. http://www.designnews.com/article/CA137910.html

Batchelor J (1981) Use of fibre reinforced composites in modern railway vehicles. Materials in Engineering 2(4):172–182

Baumgartner T, Tietje O, Spielmann M, Bandel R (2000) Ökobilanz der Swissmetro, Umweltwirkungen durch Bau und Betrieb (Teil 1) und durch induzierte Aktivitäten (Teil 2). Berne

Campbell FC (2004) Manufacturing processes for advanced composites. Elsevier, Oxford

Carruthers J (2004) The research requirements of the transport sectors to facilitate an increased usage of composite materials, Part III: The composite material research requirements of the rail industry. June 2004, ComposiTN

Dahlbo H, Ollikainen M, Peltola S, Myllymaa T, Melanen M (2007) Combining ecological and economic assessment of options for newspaper waste management. Resources, Conservation and Recycling 51:42–63

Dones R, Bauer C, Bolliger R, Burger B, Faist Emmenegger M, Frischknecht R, Heck T, Jungbluth N, Röder A (2004) Life Cycle Inventories of Energy Systems: Results for Current Systems in Switzerland and other UCTE Countries. ecoinvent report No. 5. Paul Scherrer Institut Villigen, Swiss Centre for Life Cycle Inventories, Dübendorf.

EAA (2009) European Aluminium Association website. Recycled aluminium. http://www.eaa.net/en/about-aluminium/production-process/recycled-aluminium/ Accession date 25.02.2009

Ecabert B, Wakeman MD, Blanc I, Jolliet O, Lee S, Månson JAE (2006) Coupled cost and life cycle modelling of composite car-bodies for the Korean tilting train. Proceedings of the 27th SAMPE International Conference Europe, March 2006, Paris

Frischknecht R, Jungbluth N, Althaus H-J, Doka G, Dones R, Heck T, Hellweg S, Hischier R, Nemecek T, Rebitzer G, Spielmann M (2005) The ecoinvent database: Overview and methodological framework. Int J Life Cycle Assess 10(1):3–9

Gibson TL (2000) LCA of Advanced Materials for Automotive Applications, Proceedings of The ‘Total Life Cycle Conference, Land. Sea & Air Mobility’, SAE International

Guillemot JM, Grunevald YH (2000) Les composites en construction ferroviaire, Techniques de l’Ingénieur, traité Plastiques et Composites, AM 5 650

Guinèe JB, Gorrée M, Heijungs R, Huppes G, Kleijn R, de Koning A, van Oers L, Wegener Sleeswijk A, Suh S, Udo de Haes HA, de Bruijn H, van Duin R, Huijbregts MAJ, Lindeijer E, Roorda AAH, Weidema BP (2001) Life cycle assessment — An operational guide to the ISO standards; Characterisation and Normalisation Factors. Retrieved 17.02.2004

Helms H, Lambrecht U (2007) The Potential Contribution of Light-Weighting to Reduce Transport Energy Consumption. Int J Life Cycle Assess 12(1):58–64 Special issue

Hunkeler D, Lichtenvort K, Rebitzer G (2008) Environmental life cycle costing. CRC Press. ISBN: 978-1-4200-5470-5

IDEMAT (2001) IDEMAT database. Delft University of Technology, Delft, The Netherlands

IEC60300 (1996) International Electrotechnical Commission standard, 1996, NO. 60300

ISO 14040 (2006) International Standard. Environmental management — Life cycle assessment — Principles and framework, International Organization for Standardization, Geneva.

ISO 14044 (2006) International Standard. Environmental management — Life cycle assessment — Requirements and Guidelines, International Organisation for Standardisation, Geneva.

Jolliet O, Saadé M, Cretaz P (2005) Analyse de cycle de vie comprendre et réaliser un écobilan. Presses Polytechniques et Universitaires Romandes, Lausanne

Jolliet O, Margni M, Humbert S, Rebitzer G, Rosenbaum R (2003) Impact 2002+: a new life cycle impact assessment methodology. Int J Life Cycle Assess 8(6):324–330

KELA (2005) Korean Database (extraction) for electricity production

Kirimura K, Tsujimura T, Mifune N (1997) Railway materials tending to be increasingly environment-conscious in Japan. Proceedings of the World Congress on Railway Research, Italy

Maibach K, Peter D, Seiler B (1999) Ökoinventar Transporte, Grundlagen für den ökologischen Vergleich von Transportsystemen und den Einbezug von Transportsystemen in Ökobilanzen, 2. korrigierte Auflage. Swiss National Science Foundation, Zü

Margand A, Payet J, Jolliet O (2003) Life cycle assessment of an underbody panel for car. In preparation for publication, Swiss Federal Institute of Technology of Lausanne 16 pp

Mingot S, Baumgartner T (1997) Ökobilanz Swissmetro. LCA für ökologische Optimierung & Vergleich mit anderen Verkehrsmitteln, Zürich

Nagatomo T, Miyauchi T, Tsuchiya H (1997) Preliminary investigation for life cycle assessment (LCA) of Shinkansen vehicles. Proceedings of the World Congress on Railway Research, Italy

Nolte R (2003) EVENT Evaluation of Energy Efficiency Technologies for Rolling Stock and Train Operation of Railways. Final report. International Union of Railways. Deutsche Bahn AG, Berlin

Norris G (2001) Integrating life cycle cost analysis and LCA. Int J Life Cycle Assess 6(2):118–20

Rivier RE, Tzieropoulos P, EPFL-LITEP (1987) Computer-aided planning for railway network, lines and stations. In: Computers in Railway Management, Computational Mechanics Publications. Springer-Verlag, Berlin, pp 3–16

Rebitzer G, Hunkeler D, Jolliet O (2003) LCC- The economic pillar of sustainability: methodology and application to wastewater treatment. Environmental Progress 22(4):241–249

Robinson M (2000) Applications in Train and Railways. In: Comprehensive Composite Materials. Vol. 6, Elsevier Science Ltd

Spielmann M, Kägi T, Stadler P, Tiethe O (2003) Life Cycle Inventories of Transport Services, 2003, in Ecoinvent database 1.01, Ecoinvent reports No 14, Swiss Centre for Life Cycle Inventories, Dübendorf

Spielmann M, Scholz RW (2005) Life cycle inventories of transport services: Background data for freight transport. Int J Life Cycle Assess 10(1):85–94

The Global Aluminium Recycling Committee (2006) Global Aluminium Recycling: A Cornerstone of Sustainable Development, International Aluminium Institute, London. http://www.world-aluminium.org/cache/fl0000181.pdf

Von Rozycki C et al (2003) Ecology profile of the German high-speed rail passenger transport system, ICE. Int J Life Cycle Assess 8(2):83–91

Vogtländer J, Brezet H, Hendricks C (2001) The virtual Eco-Costs ’99. Int J Life Cycle Assess 6(2):157–66

Wakeman, MD, Månson, JAE (2005) Design and Manufacture of Textile Composites Chapter 11: Cost analysis, Ed. A. Long, Woodhead, published spring 2005, Clark JP, Roth R, Eds. ‘Techno-Economic issues in materials selection’, Materials selection and design, Materials Park, OH, ASM International

Wilson M for ‘Bombardier Transportation’ (2002) Composite Materials For Railway Applications, Genoa, June 2002

Acknowledgements

This work is the result of a collaboration between Hankuk Fiber Glass Co., the Korea railroad research institute (KRRI) and Ecole Polytechnique Fédérale de Lausanne (EPFL) represented by the Laboratory of Ecosystem Management (GECOS) for the LCA study, the Composites and Polymers Technology Laboratory (LTC) for the technical cost modelling (TCM) study of candidate composite manufacturing processes, and the Laboratory for Intermodality, Transport and Planning (LITEP) for use phase energy modelling.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Tak Hur

Rights and permissions

About this article

Cite this article

Schwab Castella, P., Blanc, I., Gomez Ferrer, M. et al. Integrating life cycle costs and environmental impacts of composite rail car-bodies for a Korean train. Int J Life Cycle Assess 14, 429–442 (2009). https://doi.org/10.1007/s11367-009-0096-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-009-0096-2