Abstract

Purpose

Simulation plays a critical role in the design of products, materials, and manufacturing processes. However, there are gaps in the simulation tools used by industry to provide reliable results from which effective decisions can be made about environmental impacts at different stages of product life cycle. A holistic and systems approach to predicting impacts via sustainable manufacturing planning and simulation (SMPS) is presented in an effort to incorporate sustainability aspects across a product life cycle.

Methods

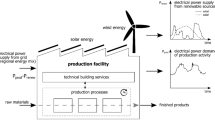

Increasingly, simulation is replacing physical tests to ensure product reliability and quality, thereby facilitating steady reductions in design and manufacturing cycles. For SMPS, we propose to extend an earlier framework developed in the Systems Integration for Manufacturing Applications (SIMA) program at the National Institute of Standards and Technology. SMPS framework has four phases, viz. design product, engineer manufacturing, engineer production system, and produce products. Each phase has its inputs, outputs, phase level activities, and sustainability-related data, metrics and tools.

Results and discussion

An automotive manufacturing scenario that highlights the potential of utilizing SMPS framework to facilitate decision making across different phases of product life cycle is presented. Various research opportunities are discussed for the SMPS framework and corresponding information models.

Conclusions

The SMPS framework built on the SIMA model has potential in aiding sustainable product development.

Similar content being viewed by others

References

Ameta G, Mani M, Sudarsan R, Feng SC, Sriram RD, Lyons K (2009) Carbon weight analysis for machining operation and allocation for redesign. Intl J Sust Eng 2(4):241–251

Banks J, Carson JS, Nelson BL, Nicol DM (2000) Discrete-event system simulation, 3rd edn. Prentice-Hall, Upper Saddle River

Barkmeyer JE (1997) SIMA reference architecture part 1—activity models. National Institute of Standards and Technology, Report No. NISTIR 5939

ISO (2006) Environmental management—life cycle assessment—principles and framework. ISO 14040:2006. http://www.iso.org/iso/catalogue_detail?csnumber=37456. Accessed August 2012

ISO (2006) Environmental management—life cycle assessment—requirements and guidelines. ISO 14044:2006. http://www.iso.org/iso/home/store/catalogue_tc/catalogue_detail.htm?csnumber=38498. Accessed August 2012

ITA (2011) International trade commission on sustainable manufacturing, http://www.ita.doc.gov/competitiveness/sustainablemanufacturing/how_doc_defines_SM.asp. Accessed August 2012

Johansson B, Mani M, Skoogh A, Leong S (2009) Discrete event simulation to generate requirements specification for sustainable manufacturing systems design. Proceedings of PerMIS'09, Gaithersburg, MD, USA

Johansson B, Mani M, Skoogh A, Leong S (2009) Discrete event simulation as requirements specification for sustainable design of manufacturing systems. Proceedings of the PERMIS09, Gaithersburg, MD, USA

Johansson B, Stahre J, Berlin J, Östergren K, Sundstrom B, Tillman A M (2008) Discrete event simulation with life cycle assessment data at a juice manufacturing system, In proceedings of the 5th FOODSIM Conference, University College Dublin, Ireland

Law AM, Kelton WD (2000) Simulation modeling and analysis, 3rd edn. McGraw-Hill, New York

Law AM, McComas MG (1999) Simulation of manufacturing systems. In: Farrington PA, Nembhard HB, Sturrock DT, Evans GW (eds) Proceedings of the 1999 Winter Simulation Conference, Pheonix, AZ, pp 56–59

Leng CF, Yingchao G (2005) Production performance improvement using des of low volume production in a paint shop. Dissertation. Chalmers University of Technology, Gothenburg, Sweden

Mahesh M, Ong SK, Nee AYC, Fuh JYH, Zhang YF (2007) Towards a generic distributed and collaborative digital manufacturing. Intl J RoboT Com- Int Manuf 23(3):267–275

Mani M, Johansson B, Lyons K, Sriram RD, Ameta G (2010) Modeling, simulation and analysis for sustainable product development. National Institute of Standards and Technology Internal Report (NISTIR)

Mani M, Lyons K, Sudarsan R, Feng SC, Sriram RD, Ameta G (2008) Introducing sustainability indices early into manufacturing process planning and scheduling. Proceedings of the 14th International Conference on Manufacturing Science and Engineering, ASME, October 07–10

Masanet E, Horvath A (2007) California air resources board’s chair’s air pollution seminar, on industrial energy analysis Website http://industrial-energy.lbl.gov/node/402/. Accessed August 2012

NACFAM (2011) National Council of advanced manufacturing defining sustainable manufacturing in the policy initiatives http://www.nacfam.org/PolicyInitiatives/SustainableManufacturing/tabid/64/Default.aspx. Accessed August 2012

Oakland JS (2003) Total quality management. Butterworth–Heinemann, Oxford

Oden JT, Belytschko T, Hughes TJR, Johnson C, Keyes D, Laub A, Petzold L, Srolovitz D, Yip S (2006) Revolutionizing engineering science through simulation: A report of the National Science Foundation blue ribbon panel on simulation-based engineering science. Arlington, VA http://www.nsf.gov/pubs/reports/sbes_final_report.pdf. Accessed August 2012

Ostergren K, Berlin J, Johansson B, Stahre J, Tillman A-M (2007) A tool for productive and environmentally efficient food production management. In: European Conference of Chemical Engineering, Copenhagen, 16–20 September 2007

Saaty TL (2008) Decision making with the analytic hierarchy process. Intl J Serv Sci 1(1):83–98

SISO (2009) Standard for core manufacturing simulation data information model: UML model CMSD Product Development Group, Simulation Interoperability Standards Organization, http://www.sisostds.org/DigitalLibrary.aspx?Command=Core_Download&EntryId=30569. Accessed August 2012

Solding P, Petku D (2005) Applying energy aspects on simulation of energy-intensive production systems. In: Kuhl ME, Steiger NM, Armstrong FB, Joines JA (eds) Proceedings of the 2005 Winter Simulation Conference, Orlando, FL, USA

Solding P, Thollander P (2006) Increased energy efficiency in a swedish iron foundry through use of discrete event simulation, In: Perrone LF, Wieland FP, Liu J, Lawson BG, Nicol DM, Fujimoto RM (eds) Proceedings of the 2006 Winter Simulation Conference, Monterey, CA, USA

USCAR (2008) Technology roadmap for energy reduction in automotive manufacturing, workshop report, U.S. Council for automotive research. http://www1.eere.energy.gov/manufacturing/intensiveprocesses/pdfs/auto_industry_roadmap.pdf. Accessed August 2012

Conflict of interest

The work described was funded by the US Government and is not subject to copyright. No approval or endorsement of any commercial product by the National Institute of Standards and Technology is intended or implied.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Sangwon Suh

Rights and permissions

About this article

Cite this article

Mani, M., Johansson, B., Lyons, K.W. et al. Simulation and analysis for sustainable product development. Int J Life Cycle Assess 18, 1129–1136 (2013). https://doi.org/10.1007/s11367-012-0538-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-012-0538-0